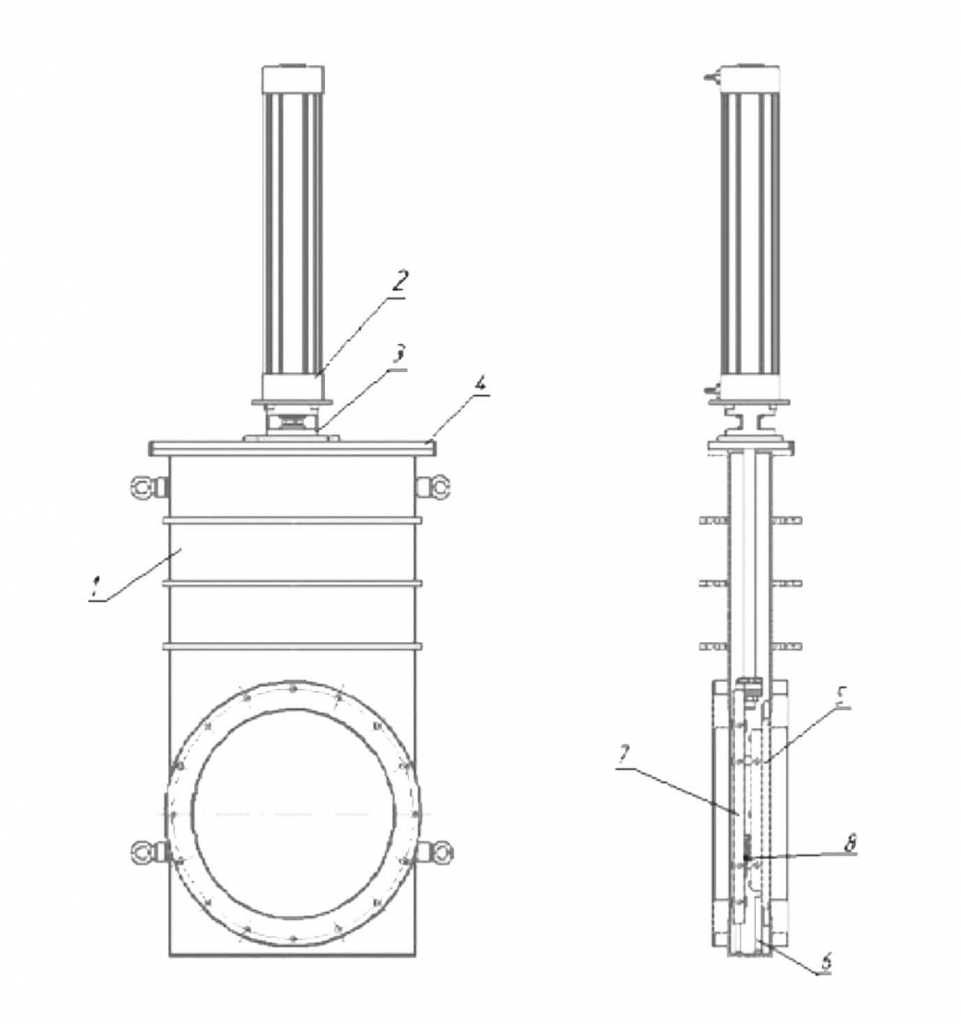

The main components related to the two types of those produced by the NPO “GKMP” LLC are shown on the Picture 1 as an example of a shut-off with a rubber seal.

1. Housing

2. Pneumatic cylinder

3. Support

4. Housing cap

5. Poppet

6. Retainer poppet

7. Frame

8. SpringThe housing is a leakproof vacuum chamber attached by the flanges to the vacuum system. Unlike vacuum valves, the gate valve poppet moves perpendicularly to the gas flow thus ensuring its maximum conductivity when opened. This is the reason why vacuum shut-offs are the best to equip the hardware operating in molecular gas mode, like turbomolecular, ion, getter and cryogenic pumps.

Vacuum shut-offs can be operated manually, pneumatically or electromechanically. Shut-offs can be manufactured with bellows or elastomer rod seal.

The NPO “GKMP” LLC manufactures straight shut-offs with pneumatic drive designed to close a vacuum system.

Application: vacuum systems for electronic components production, electric devices, energy, tool construction, machine construction and in scientific research.

Shut-offs are equipped with pneumatic drive. Operating medium – air or gases that do not induce corrosion. Shut-offs are equipped with the flanges of different dimensions with the standard fitting ISO-K/ISO-F. Shut-offs manufactured correspond to the NF regulation category 4 per GOST 15150.

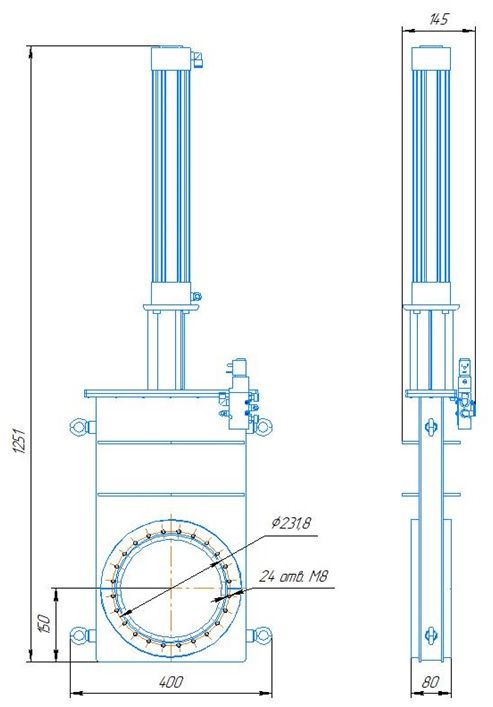

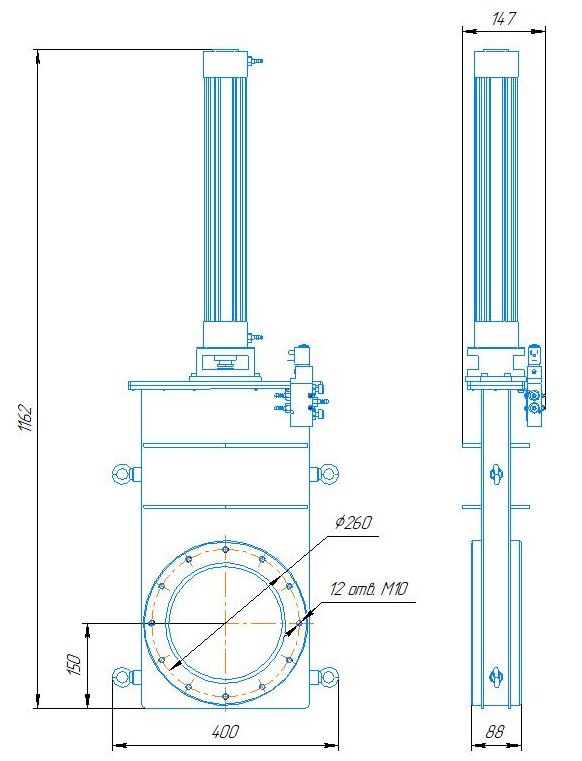

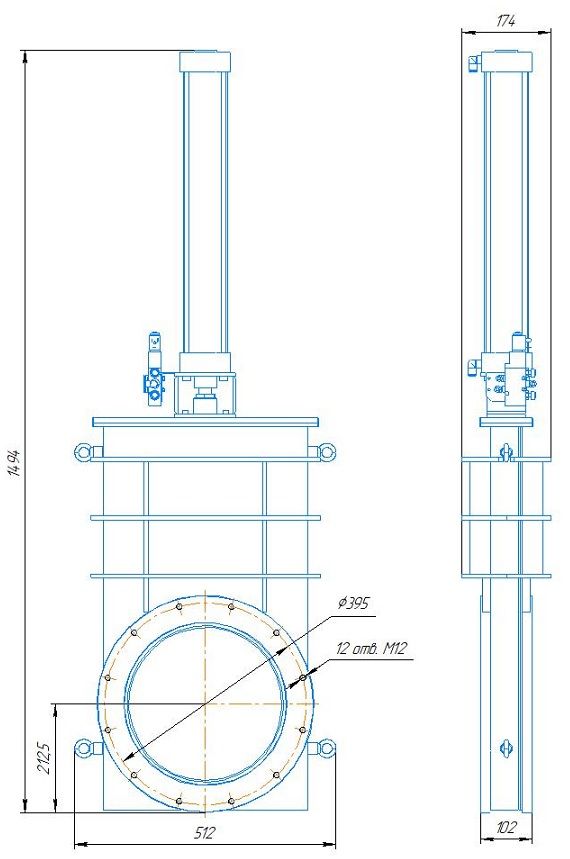

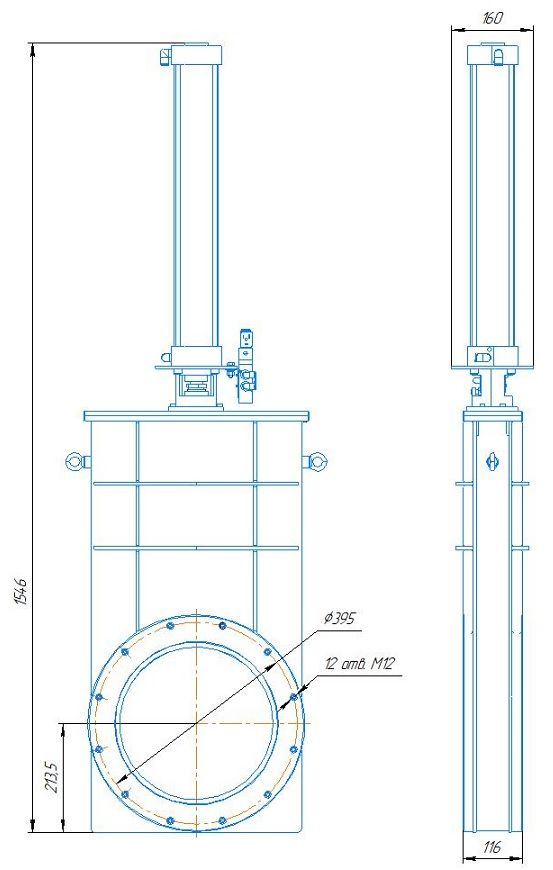

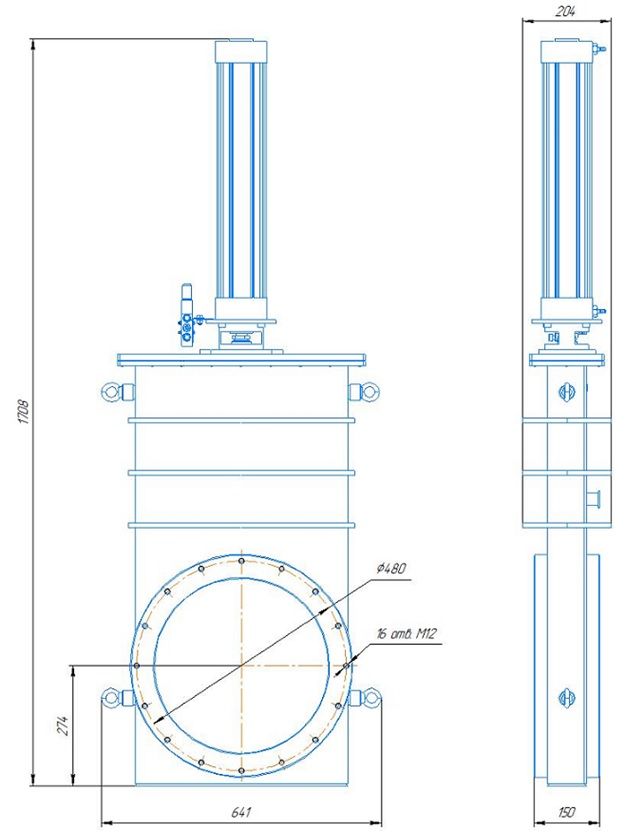

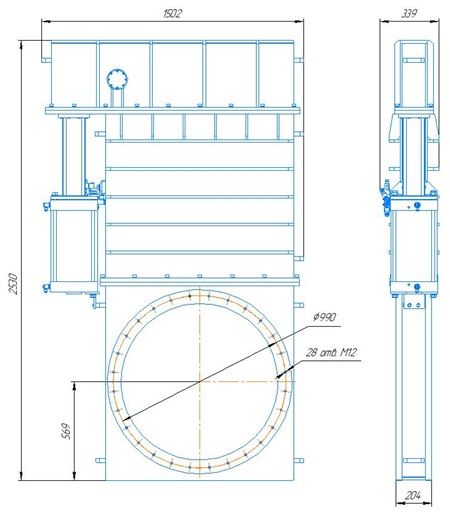

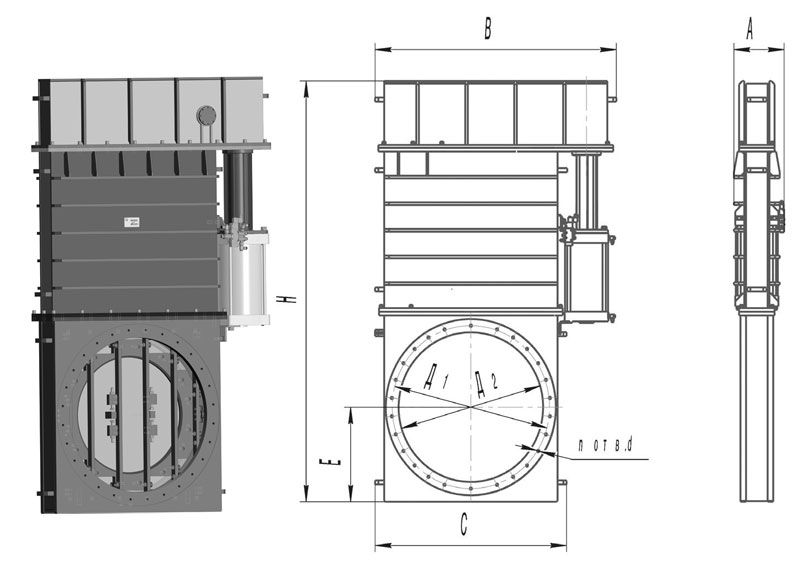

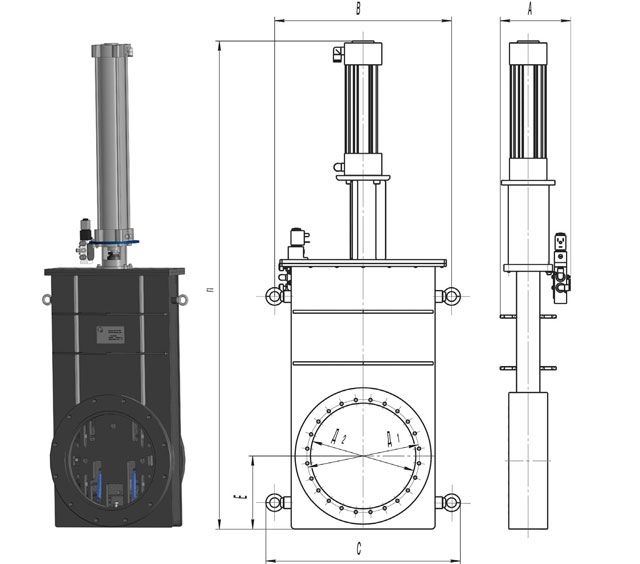

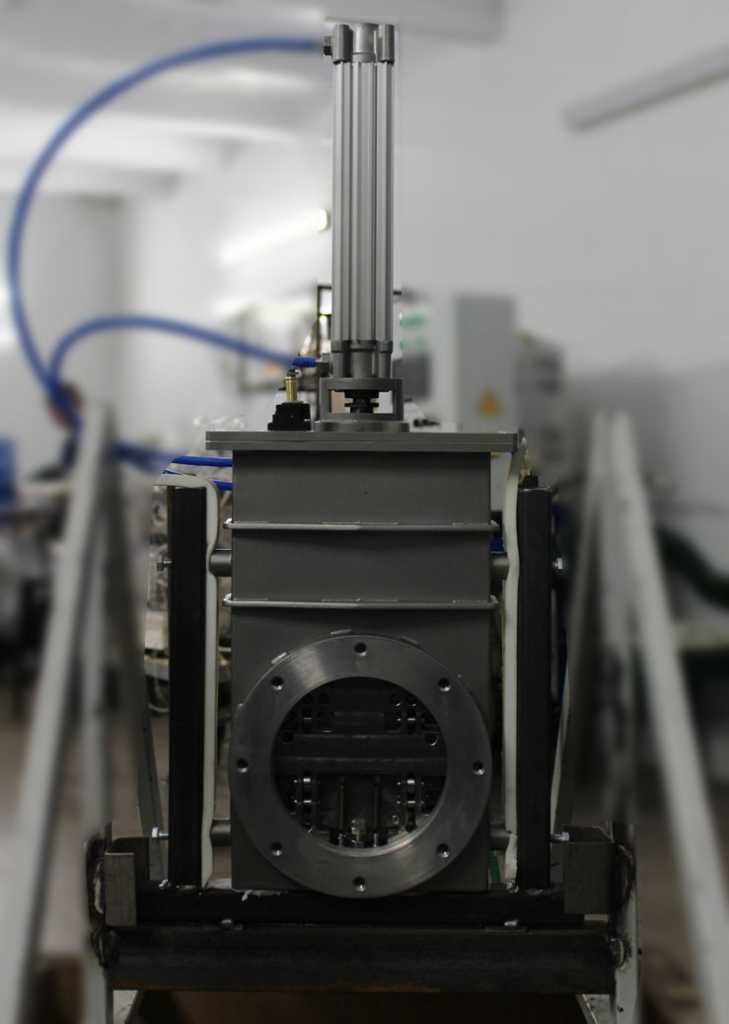

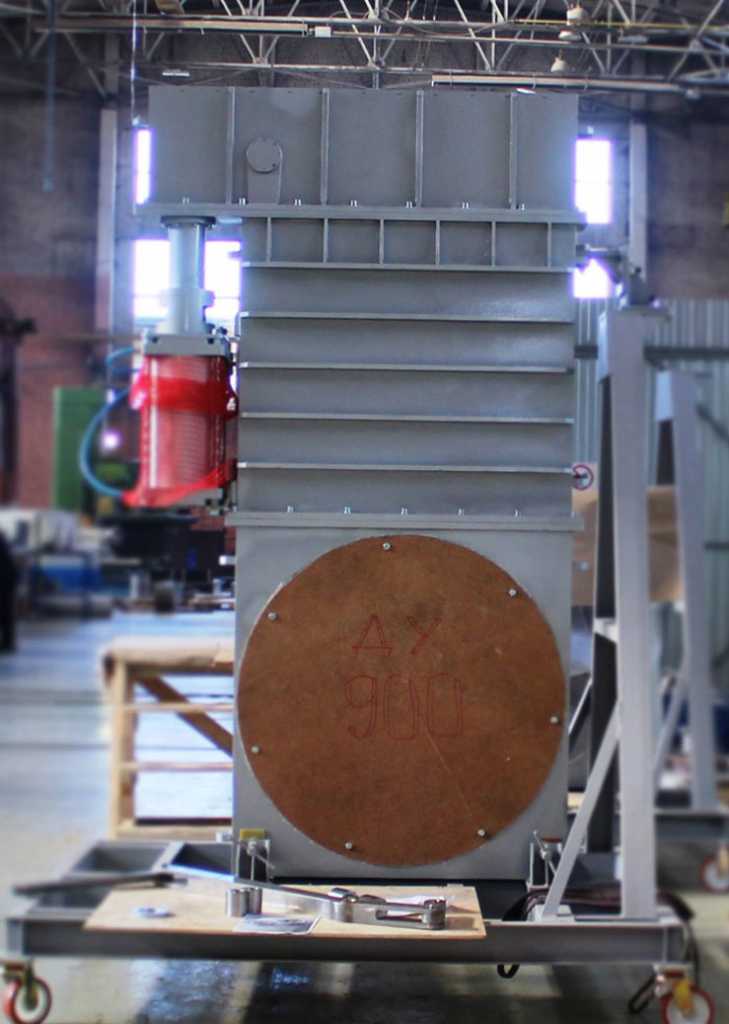

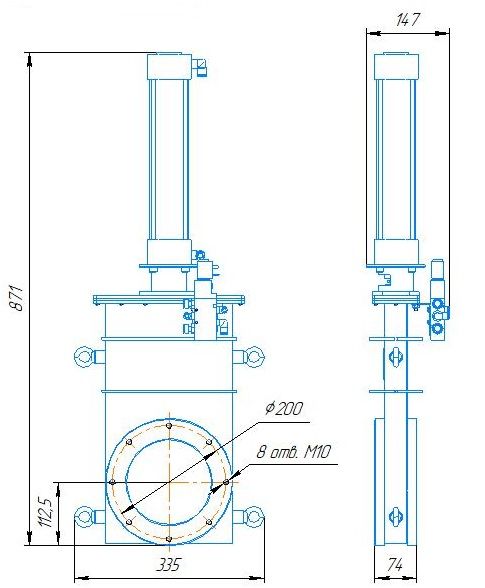

The general appearance of shut-offs is given on Pictures 2 and 3*.

Pic. 2 Pic. 3

Pic. 3

The general appearance of shut-offs with rubber seal and overhead pneumatic cylinder.

Reference designation of shut-offs (for order):

ЗПМ.1. ХХХ – ТУ 28.14.13-018-65807096-2021;

ЗПМ.2. ХХХ – ТУ 28.14.13-018-65807096-2021;

ЗПМ – pneumomechanical shut-off ;

1 – backing within range 1•105 до 1•10-3 Ра;

2 – high vacuum within range 1•10-3 до 1•10-5 Ра;

ХХХ - pipe size in mm.

Delivery time: 4 months once the advance payment is provided.

Appearance of a shut-off may differ depending on its gage.

Table 1. Dimensions and mass of shut-offs per Design documentation.

|

Dу of the shut-off |

Dimensions, mm |

n of mating part |

Mass, kg (not to exceed) |

|||||||

|

H |

B |

E |

C |

A |

D1 |

D2 |

d |

|||

|

Dy 160 |

871 |

300 |

112 |

335 |

139 |

200 |

150 |

М10 |

8 |

30 |

|

Dy 200-1 |

1142 |

367 |

155 |

398 |

143 |

260 |

200 |

М10 |

12 |

60 |

|

Dy 200-2 |

1251 |

364 |

150 |

400 |

144 |

232 |

200 |

М8 |

24 |

50 |

|

Dy 320-1 |

1494 |

476 |

212 |

512 |

173 |

395 |

306 |

М12 |

16 |

100 |

|

Dy 400-1 |

1704 |

5944 |

269 |

641 |

204 |

480 |

400 |

М12 |

16 |

190 |

|

Dy 900-2 |

2530 |

1502 |

569 |

1112 |

- |

980 |

900 |

М16 |

28 |

1510 |

Table 2. Main characteristics of shut-offs.

| Designation |

Shut-off nominal diameter, Dу |

||||||

|

160 |

200 |

320 |

400 |

630 |

900 |

1250 |

|

|

Operating air pressure, bar |

4-6 |

4-6 |

5-6 |

5-6 |

5-6 |

5-6 |

5-6 |

|

Open/closure time, sec |

4/4 |

4/4 |

4/4 |

6/5 |

10/11 |

16/15 |

18/17 |

|

Pressure difference to open a shut-off, MPa (mmHg) (not to exceed) |

0,106 (800) |

0,106 (800) |

0,106 (800) |

0,106 (800) |

0,106 (800) |

0,106 (800) |

0,106 (800) |

|

Helium leak rate, mm Hg•l/sec |

˂1*10-9 |

˂1*10-9 |

˂1*10-9 |

˂1*10-9 |

˂1*10-9 |

˂1*10-9 |

˂1*10-9 |

|

Ultimate operatingpressureinthevacuumchamber, Pa (mm Hg), (not to exceed) |

0,067 (5*10-4) |

0,067 (5*10-4) |

0,067 (5*10-4) |

0,067 (5*10-4) |

0,067 (5*10-4) |

0,067 (5*10-4) |

0,067 (5*10-4) |

|

Poppet shall be hermetically clamped to the housing at residual pressure, Pa (mmHg) |

0,067 (5*10-4) |

0,067 (5*10-4) |

0,067 (5*10-4) |

0,067 (5*10-4) |

0,067 (5*10-4) |

0,067 (5*10-4) |

0,067 (5*10-4) |

|

Mounting position |

Vertical Horizontal |

Vertical Horizontal |

Vertical Horizontal |

Vertical Horizontal |

Vertical Horizontal |

Vertical Horizontal |

Vertical Horizontal |

|

Warm-uptemperaturewhentheshut-offis open, ºС |

200* |

200* |

200* |

200* |

200* |

200* |

200* |

|

Warm-uptemperaturewhentheshut-offis open, ºС |

150* |

150* |

150* |

150* |

150* |

150* |

150* |

Manufacturer (Supplier) warranty

The Manufacturer (Supplier) guarantees that shut-offs correspond to requirements of relevant technical conditions and regulatory documents provided that User complies with required conditions of transportation, storage, mounting and use.

Warranty life time of a shut-off is 112 months once commissioned. Warranty shelf life is 6 months. Warranty does not cover cases when the user does not comply with the storage rules, improper mounting and use of the shut-off.

Storage and transportation

Once shut-offs arrives at the storage site, the person in charge shall perform a number of actions to properly locate the goods as provided by service instruction.

Transportation

Vacuum shut-off is packed at manufacturer’s premises as required by the Design documentation.

Storage and transportation conditions

Shelf life is 6 months provided that storage requirements are met.

Storage conditions (1) L per GOST 15150 at the air temperature from +5 to +40ºC and relative air humidity 80% at 25ºC. Shut-offs can be transported with any vehicles. When loaded, a shut-off shall be protected from any mechanical damage, either internal surfaces from contamination. Companies and organizations that use shut-offs in their activity, shall keep those in proper condition and ensure the safe operation strictly in compliance with operational documents.

The proper technical maintenance and use of industrial equipment enable to cut substantially the maintenance costs and off period.

When using the shut-offs the following maintenance is performed:

-

Daily technical maintenance

-

Monthly technical maintenance

-

6-month technical maintenance

Shut-off reliability factor:

-

Average failure-free cycle is over 1200 h

-

Average lifetime is over 10 years

-

Average recovery time is no more than 5 h

*Shut-off leakage is considered a failure criterion

|

|

|

|

Vacuum shut-offs

Vacuum shut-off ДУ 160-1 ПГБА.976.00.000

| Operating air pressure, bar |

4-6 |

| Opening/closing time, sec |

4/4 |

| Pressure difference to open a shut-off ), MPa (mmHg), not to exceed |

0.106 (800) |

| Helium leak rate, mm Hg•l /sec |

<1*10-9 |

| Max. operating pressure in the vacuum chamber, Pa (mmHg), not to exceed |

0.067 (5*10-4) |

| Poppet shall be hermetically clamped to the housing at residual pressure, Pa (mmHg) |

0.067 (5*10-4) |

| Mounting position |

vertical horizontal |

| Warm-up temperature when the shutoff is open, oС (from 1 • 10 -3 to 1•10-5 Pa) |

200 |

| Warm-up temperature when the shutoff is closed, oС(from 1•10-3 to 1•10-5 Pa) |

150 |

| Mass, kg, not to exceed |

30 |

| Rod seal |

bellow |

| Flange |

ISO-К ISO-F |

| Drive |

pneumatic |

| Operating medium |

Water or gases that do not induce corrosion |

Vacuum shut-offs

Vacuum shut-off ДУ 200-2 ПГБА.990.00.000

| Operating air pressure, bar |

4-6 |

| Opening/closing time, sec |

4/4 |

| Pressure difference to open a shut-off ), MPa (mmHg), not to exceed |

0.106 (800) |

| Helium leak rate, mm Hg•l /sec |

<1*10-9 |

| Max. operating pressure in the vacuum chamber, Pa (mmHg), not to exceed |

0.067 (5*10-4) |

| Poppet shall be hermetically clamped to the housing at residual pressure, Pa (mmHg) |

0.067 (5*10-4) |

| Mounting position |

vertical horizontal |

| Warm-up temperature when the shutoff is open, oС (from 1 • 10 -3 to 1•10-5 Pa) |

200 |

| Warm-up temperature when the shutoff is closed, oС(from 1•10-3 to 1•10-5 Pa) |

150 |

| Mass, kg, not to exceed |

50 |

| Rod seal |

bellow |

| Flange |

ISO-К ISO-F |

| Drive |

pneumatic |

| Operating medium |

Water or gases that do not induce corrosion |

Vacuum shut-offs

Vacuum shut-off ДУ 200-1 ПГБА.975.00.000

| Operating air pressure, bar |

4-6 |

| Opening/closing time, sec |

4/4 |

| Pressure difference to open a shut-off ), MPa (mmHg), not to exceed |

0.106 (800) |

| Helium leak rate, mm Hg•l /sec |

<1*10-9 |

| Max. operating pressure in the vacuum chamber, Pa (mmHg), not to exceed |

0.067 (5*10-4) |

| Poppet shall be hermetically clamped to the housing at residual pressure, Pa (mmHg) |

0.067 (5*10-4) |

| Mounting position |

vertical horizontal |

| Warm-up temperature when the shutoff is open, oС (from 1 • 10 -3 to 1•10-5 Pa) |

200 |

| Warm-up temperature when the shutoff is closed, oС(from 1•10-3 to 1•10-5 Pa) |

150 |

| Mass, kg, not to exceed |

60 |

| Rod seal |

elastomer |

| Flange |

ISO-К ISO-F |

| Drive |

pneumatic |

| Operating medium |

Water or gases that do not induce corrosion |

Vacuum shut-offs

Vacuum shut-off ДУ 320-1 ПГБА.942.00.000

| Operating air pressure, bar |

5-7 |

| Opening/closing time, sec |

4/4 |

| Pressure difference to open a shut-off ), MPa (mmHg), not to exceed |

0.106 (800) |

| Helium leak rate, mm Hg•l /sec |

<1*10-9 |

| Max. operating pressure in the vacuum chamber, Pa (mmHg), not to exceed |

0.067 (5*10-4) |

| Poppet shall be hermetically clamped to the housing at residual pressure, Pa (mmHg) |

0.067 (5*10-4) |

| Mounting position |

vertical horizontal |

| Warm-up temperature when the shutoff is open, oС (from 1 • 10 -3 to 1•10-5 Pa) |

200 |

| Warm-up temperature when the shutoff is closed, oС(from 1•10-3 to 1•10-5 Pa) |

150 |

| Mass, kg, not to exceed |

100 |

| Rod seal |

elastomer |

| Flange |

ISO-К ISO-F |

| Drive |

pneumatic |

| Operating medium |

Water or gases that do not induce corrosion |

Vacuum shut-offs

Vacuum shut-off ДУ 320-2 ПГБА.503.00.000

| Operating air pressure, bar |

5-7 |

| Opening/closing time, sec |

4/4 |

| Pressure difference to open a shut-off ), MPa (mmHg), not to exceed |

0.106 (800) |

| Helium leak rate, mm Hg•l /sec |

<1*10-9 |

| Max. operating pressure in the vacuum chamber, Pa (mmHg), not to exceed |

0.067 (5*10-4) |

| Poppet shall be hermetically clamped to the housing at residual pressure, Pa (mmHg) |

0.067 (5*10-4) |

| Mounting position |

vertical horizontal |

| Warm-up temperature when the shutoff is open, oС (from 1 • 10 -3 to 1•10-5 Pa) |

200 |

| Warm-up temperature when the shutoff is closed, oС(from 1•10-3 to 1•10-5 Pa) |

150 |

| Mass, kg, not to exceed |

110 |

| Rod seal |

elastomer |

| Flange |

ISO-К ISO-F |

| Drive |

pneumatic |

| Operating medium |

Water or gases that do not induce corrosion |

Vacuum shut-offs

Vacuum shut-off ДУ 400-1 ПГБА.962.00.000

| Operating air pressure, bar |

4-8 |

| Opening/closing time, sec |

6/5 |

| Pressure difference to open a shut-off ), MPa (mmHg), not to exceed |

0.106 (800) |

| Helium leak rate, mm Hg•l /sec |

<1*10-9 |

| Max. operating pressure in the vacuum chamber, Pa (mmHg), not to exceed |

0.067 (5*10-4) |

| Poppet shall be hermetically clamped to the housing at residual pressure, Pa (mmHg) |

0.067 (5*10-4) |

| Mounting position |

vertical horizontal |

| Warm-up temperature when the shutoff is open, oС (from 1 • 10 -3 to 1•10-5 Pa) |

200 |

| Warm-up temperature when the shutoff is closed, oС(from 1•10-3 to 1•10-5 Pa) |

150 |

| Mass, kg, not to exceed |

190 |

| Rod seal |

elastomer |

| Flange |

ISO-К ISO-F |

| Drive |

pneumatic |

| Operating medium |

Water or gases that do not induce corrosion |

Vacuum shut-offs

Vacuum shut-off ДУ 900-2 ПГБА.501.00.000

| Operating air pressure, bar |

5-7 |

| Opening/closing time, sec |

16/15 |

| Pressure difference to open a shut-off ), MPa (mmHg), not to exceed |

0.106 (800) |

| Helium leak rate, mm Hg•l /sec |

<1*10-9 |

| Max. operating pressure in the vacuum chamber, Pa (mmHg), not to exceed |

0.067 (5*10-4) |

| Poppet shall be hermetically clamped to the housing at residual pressure, Pa (mmHg) |

0.067 (5*10-4) |

| Mounting position |

vertical horizontal |

| Warm-up temperature when the shutoff is open, oС (from 1 • 10 -3 to 1•10-5 Pa) |

200 |

| Warm-up temperature when the shutoff is closed, oС(from 1•10-3 to 1•10-5 Pa) |

150 |

| Mass, kg, not to exceed |

1510 |

| Rod seal |

bellow |

| Flange |

ISO-К ISO-F |

| Drive |

pneumatic |

| Operating medium |

Water or gases that do not induce corrosion |