Manufacture of specific vacuum furnaces exclusively for the needs of your production

Manufacture of specific vacuum furnaces exclusively for the needs of your production

Training of Customer’s staff

Training of Customer’s staff

Commissioning and supervised mounting

Commissioning and supervised mounting

Repair, maintenance and upgrade of existing metal hoses

Repair, maintenance and upgrade of existing metal hoses

Nominal parameters

- DN from 6 to 16 mm (Pmax from 1.1 to 44.0 MPa);

- DN from 20 to 50 mm (Pmax from 0.4 to 16.0 MPa);

- DN from 65 to 250 mm (Pmax from 0.03 to 6.0 MPa);

- DN from 300 mm (Pmax from 0.03 to 1.3 MPa);

- Length from 0.3 to 6 m;

- Operating temperature from -270 to +600 ºC

- *DN –abbreviation code

- *detailed information about a characteristic, like temperature or maximal length

Bellow types

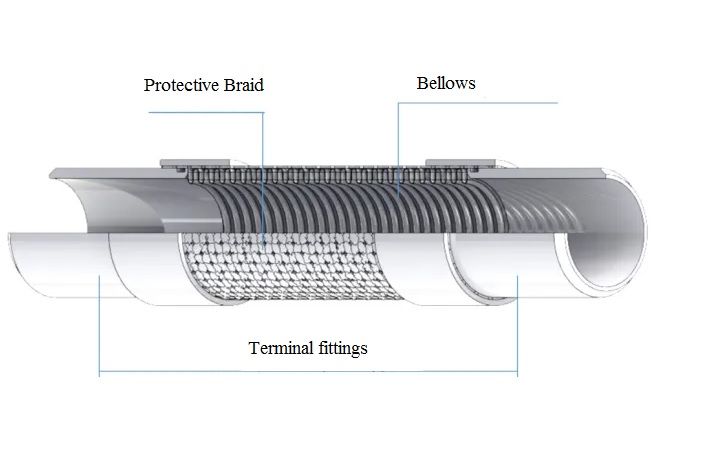

Bellow is an internal part of a metal hose that ensures flexibility exposed to leak tests while production process.

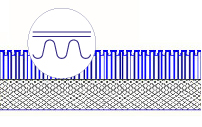

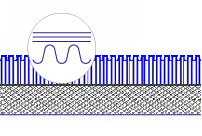

Braid types

Braid is an external part of a bellow that consists of stainless-steel wire strands over 0.3 mm thick, depending on diameter.

Stainless-steel metal hoses are braided with cutting-edge braiding machines. Braid operates not only as the shielding that protects the internal flexible bellow of the metal hose from mechanical damage and aggressive environment.

A high-pressure metal hose braid is a crucial component that has a direct effect on technical characteristics of the end item, especially its ability withstand the required operating pressure: when a metal hose with a single braid is not strong enough (one layer of wire strands), one puts the second or even the third one.