Vacuum coating systems

The processes of applying thin films in a vacuum are the basis of most technologies of modern microelectronics, aircraft manufacturing, instrument making, metalworking, medicine, nuclear energy.

Benefits of vacuum sputtering machines produced by the “NPO “GKMP” LLC

The “NPO “GKMP” LLC guarantees compliance with safety standards, as well as maintenance and replacement of facilities in case of defects.

State-of-the-art production policy adopted within the territory of the Russian Federation.

Customized production: we produce facilities for vacuum sputtering per Customer’s Technical Assignment considering specific requirements of the latter. The selection of components is to be approved by the Customer.

One of advantages proposed by vacuum sputtering facilities is the wide range of mechanics under cover and inside the chamber that enables to create layers with different properties, like conductivity, optical transparency or reflection power.

Enables to create hybrid facilities.

Ensures cleanliness and quality films, as well as operation with different materials and base types.

Vacuum sputtering furnaces are used to produce semiconductor devices and integral circuits, as well as in optical and electronic instrumentation. These facilities are perfect for thin films to coat substrates of different materials. This technique enables to create layers of different properties, such as conductivity, optical transparency or reflective power.

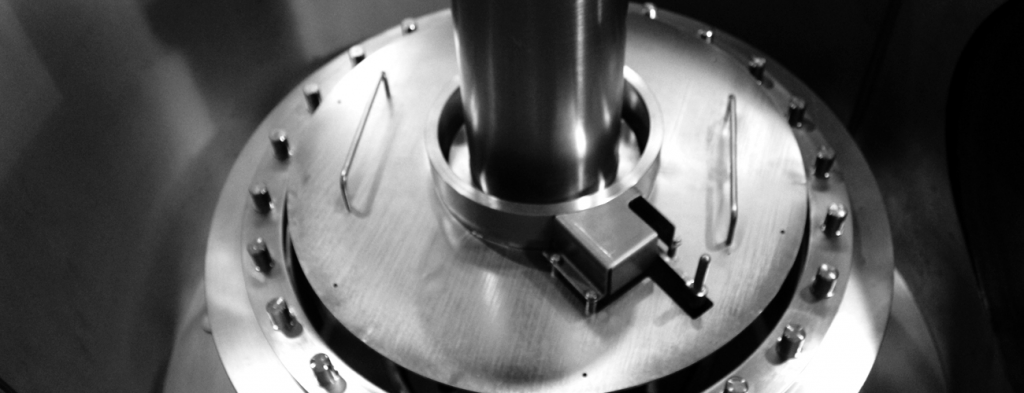

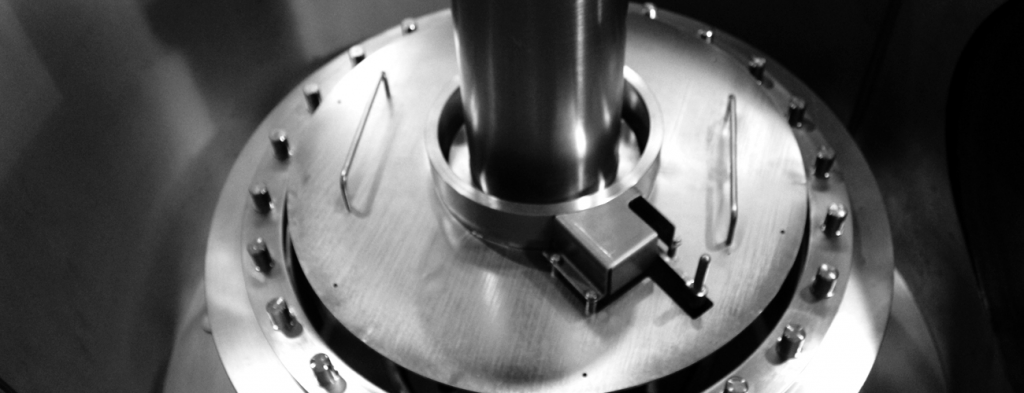

Vacuum sputtering takes place in deep vacuum to ensure cleanliness and quality of coated films. The facility consists of the following components:

- Source of material – winded coils, trays with powder or other sources of material to be sputtered

- Material handling system – includes mechanisms to move materials from source to the substrate.

- Sputtering chamber – a vacuum vessel equipped with sputtering heads and substrate holders.

- Control system – controls all the sputtering parameters, such as the substrate temperature, pressure inside the chamber, sputtering speed and others.

Vacuum sputtering facilities can differ in dimensions and configuration, depending on required efficiency and type of material sputtered. Some of them are capable to work with several substrates at the same time to ensure better efficiency and lower costs.

The “NPO “GKMP” LLC produces vacuum sputtering facilities mostly of resistive and magnetron types. Once a preliminary agreement with the Customeris reached, such a facility can be manufactured with electron-beam evaporation feature. Thanks to the in-the-house production of heating elements, magnetrons and vacuum chambers, sealed feedthrough, transportation containers, force transfer mechanisms and other high-tech elements, the Customer can select a vacuum sputtering facility of the desired configuration.

The majority of technologies in advanced microelectronics, aviation, instrumentation, metal processing, medicine and nuclear energy are based on thin filming processes. A large number of state-of-the-art construction materials used in most critical items are produced with the help of vacuum sputtering facilities.Application: standard production processes of advanced microelectronic circuits, condensers, semiconductor elements, electric vacuum devices, protective coating of metal processing instruments, antifriction coating of machine parts, medicine, decorative coatings etc.

The “NPO “GKMP” LLC produces vacuum sputtering facilities with non-standard dimensions of operating area per Customer’s specification.

Why choose us? Industrial thermal equipment

Get your catalog of industrial thermal equipment