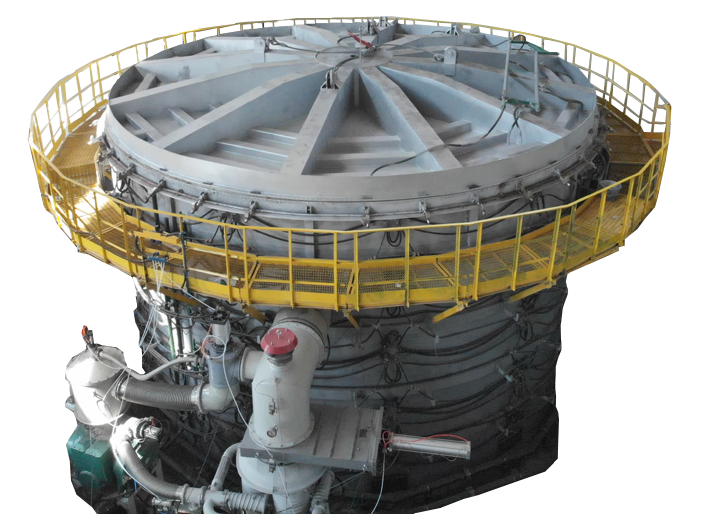

Large-volume bell lift type furnaces

This type of furnace is designed for serial or large-scale production, as well as for processing large products.

More

*On request

We will tell you in detail about our products, types and cost of delivery, prepare an individual offer and develop a technical specification

Other products

Get your catalog of industrial thermal equipment

Please fill in your telephone number and our experts will call you back

Why choose us?

Affordable prices. The cost is calculated depending on requirements set forth in technical assignment.

Qualified personnel. Our well-trained staff will complete a task of any complexity.

High quality. We use only high-quality raw materials and keep up with the relevant technologies.

Full service cycle. Apart from production itself, we provide additional services, from comissioning to subsequent maintenance.

Wide range of products. Thanks to our long-standingand well-alligned cooperation with numerous companies, we constantly look for new challenges.

One-of-the-kind customized products. We work on approved technical assignment based on relevant standards and regulation.

Ordering products/services

Получить консультацию

Подробно расскажем о наших товарах, видах и стоимости доставки,

подготовим индивидуальное предложение для оптовых клиентов!

Задать вопрос

Подробно расскажем о наших товарах, видах и стоимости доставки,

подготовим индивидуальное предложение для оптовых клиентов!

Your name E-mail Phone

Your request

Sent