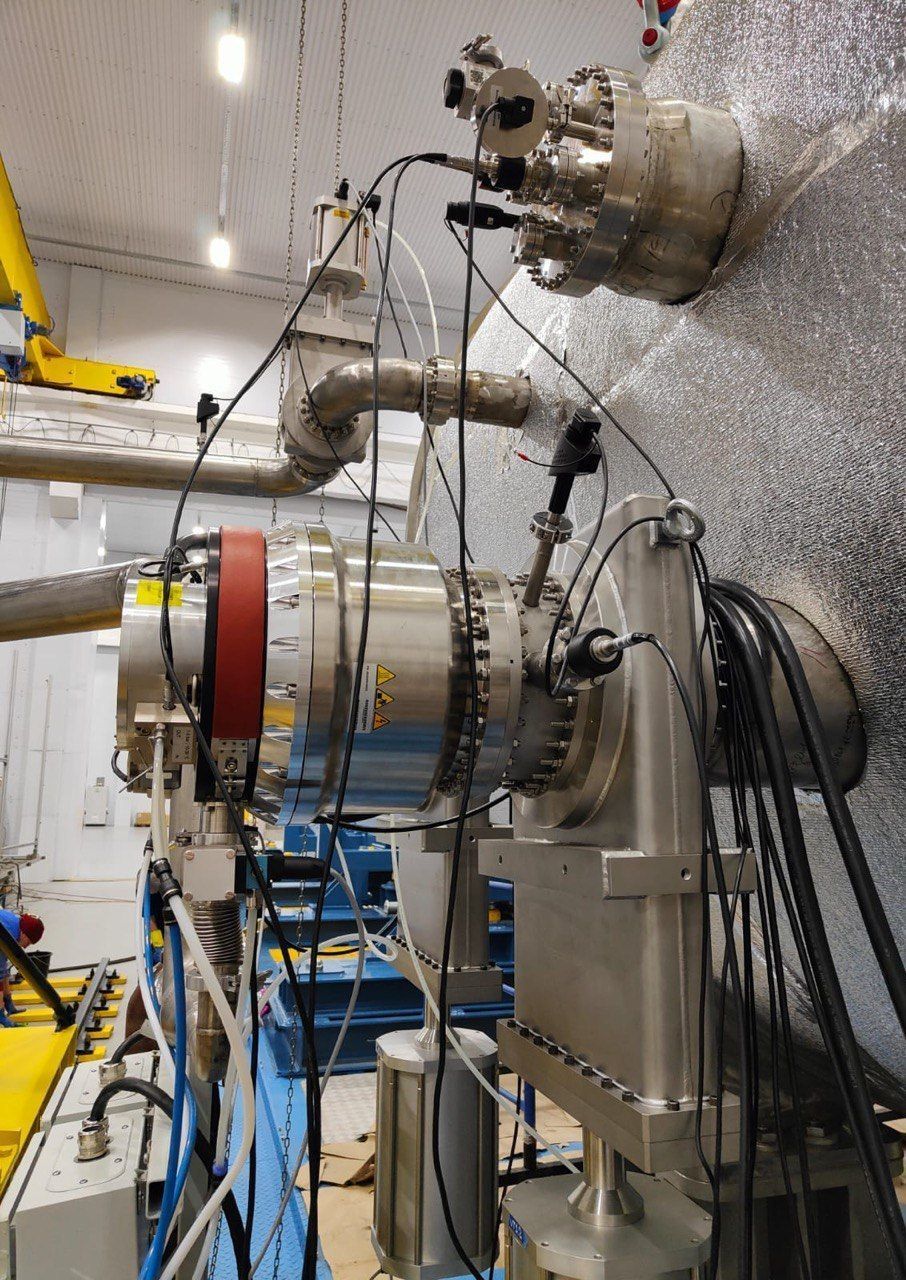

Upgrade of vacuum chambers and test facilities

The “NPO “GKMP” LLC provides services aimed at upgrading of vacuum chambers and test facilities in order to restore and improve their performances. The most valuable element of a vacuum system is a vacuum chamber, as it cost may exceed half of all the expenses related to a brand-new facility. Usually the upgrade of a vacuum facility performed by our specialists cover the full replacement of components including activities aimed at restoration of the vacuum chamber performances.

Cooperation with our company involves a maintenance agreement that sets forth a free of charge audit of your vacuum equipment stock. Based on results obtained we prepare a report enlisting recommendations to replace/upgrade, as well as on maintenance of the system and its components. Further you submit an application to perform the required services and we provide you our best proposal.

Project implementation

- Acceptance

- Rating

- Analysis

- The deal

- Preparation

- The process

- Delivery

Acceptance and evaluation: at this stage all materials and hardware necessary for further implementation of the project are accepted. Moreover, quality and conformity assessment is made to make sure that the project is in line with requirements.

Analysis and transaction: this stage covers analysis of all data and materials, as well as transactions and agreements to be entered into between suppliers and contractors.

Preparation and production flow: this stage includes preparation of all required documents and schedules related to the project. The released product or services rendered shall be in accordance with the requirements of the project.

Commissioning and completion of the project: at the last stage the project is handed over to the customer, the works performed are subject to quality inspection, possible defects are rectified, if any. After that the project is considered completed and ready for use.

Read more

Upgrade of vacuum chambers and test facilities

Upgrade of the pumping system:

- Replacement of vacuum pumps, installation of a booster pump, it is possible to build-up an oil-free pumping system of dry vacuum.

- Fault detection of vacuum chamber (grinding and polishing, plugging of leaks).

- Full replacement of vacuum fittings (valves, shut-offs, adapters, bellows etc.

- Replacement of rotary feed through and technical rubber parts.

Modernization of the element base:

- Full replacement of electric technical parts.

- Manufacture of an up-to-date facility control unit.

- Development and adjustment of an automated process control system.

- Installation of cutting-edge vacuum meters and vacuum sensors.

Functional improvements:

- Replacement of functional components: magnetrons, ion sources, electron beam gun etc.

- Installation of the cooling jacket, heating system, substrate rotation jig, lighting system etc.

- Deep upgrade of vacuum chamber design.

- Change of the facility’s functional purpose.

Upgrade of vacuum systems and facilities

In order to address the upgrade of vacuum system and facilities, our specialists analyze the technical process and propose the most efficient solution. The process includes the following milestones:

- Purpose of upgrade, i.e. which performances require improvement.

- Engineering design, that implies either selection of already existing or development of new components to implement the project and their further integration with the existing operational system (at mechanical, electrical and software level).

- Purchase/ manufacture of required materials and hardware.

- Actual upgrade of the hardware, i.e. integration of new elements in the existing system. Depending on the scale, the integration may require either taking out of service the operating hardware for entire upgrade period, or gradual upgrade with partial shut-down of the hardware and minimal downtime of the line during operations (provided that the transfer from previously used components to the new ones is done properly).

- Commissioning and testing of the new equipment including quality inspection of the end product to confirm successful improvement of performances.