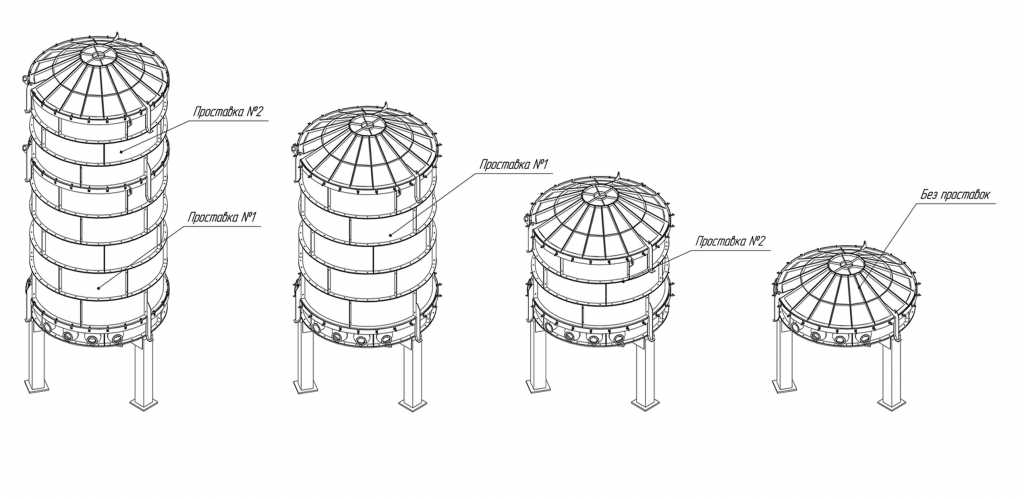

Manufacture of specific vacuum furnaces exclusively for the needs of your production

Manufacture of specific vacuum furnaces exclusively for the needs of your production

Training of Customer’s staff

Training of Customer’s staff

Commissioning and supervised mounting

Commissioning and supervised mounting

Repair, maintenance and upgrade of existing vacuum equipment

Repair, maintenance and upgrade of existing vacuum equipment

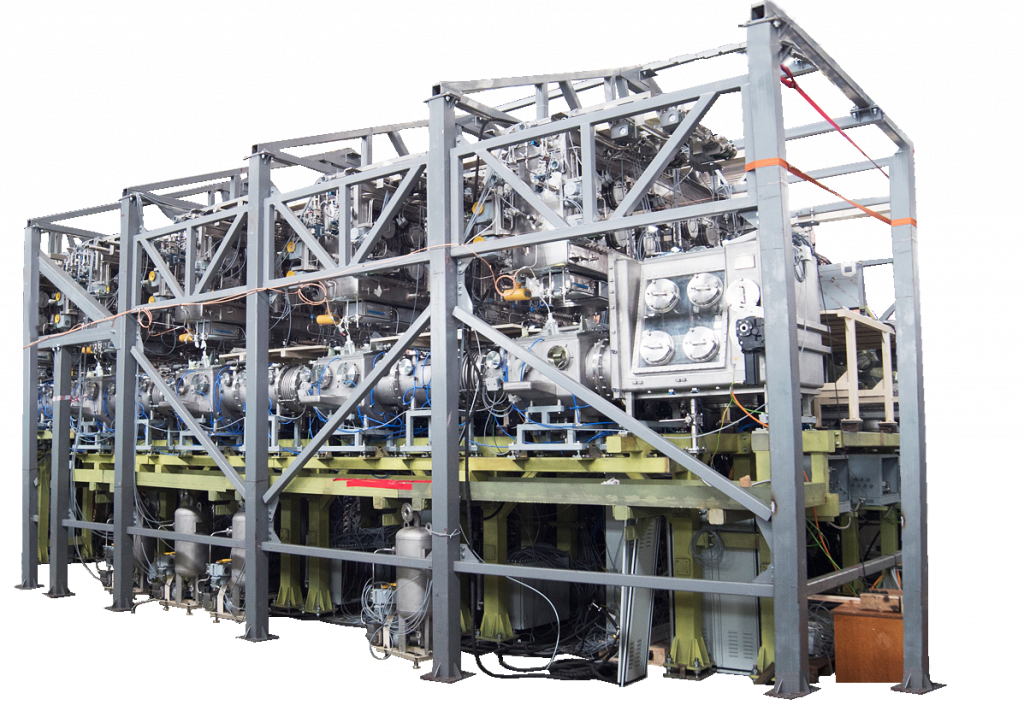

Modern technologies and a powerful production base ensure a high level of quality in the development and design of unique vacuum equipment, which allows us to achieve technical characteristics that are unattainable for competitors.

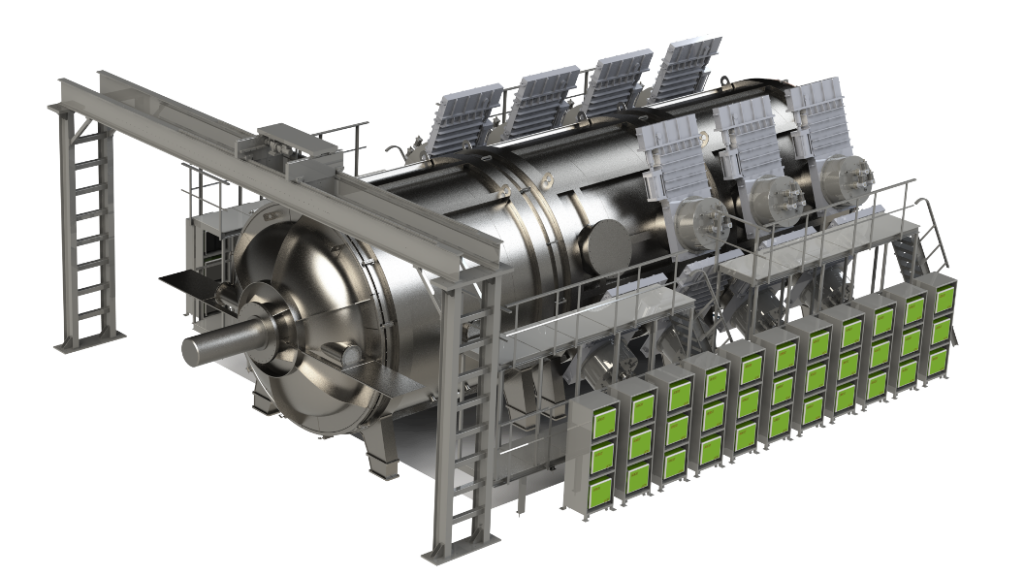

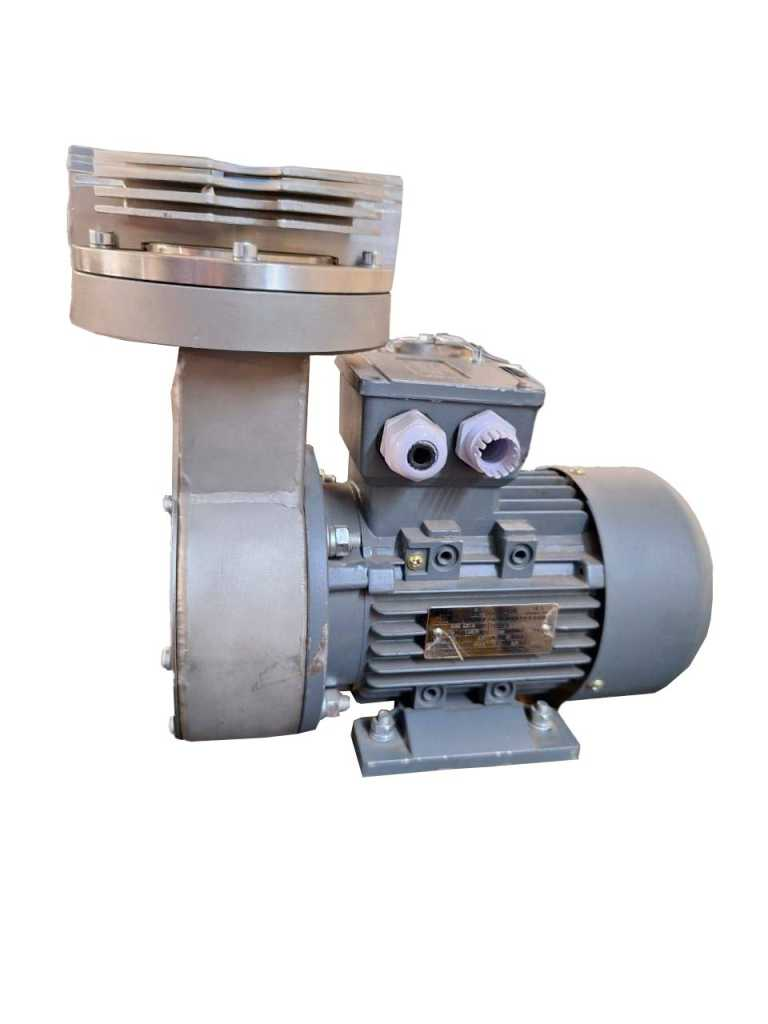

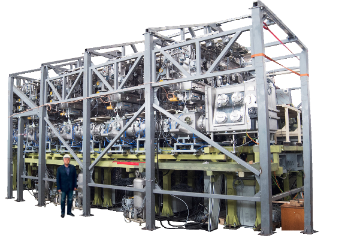

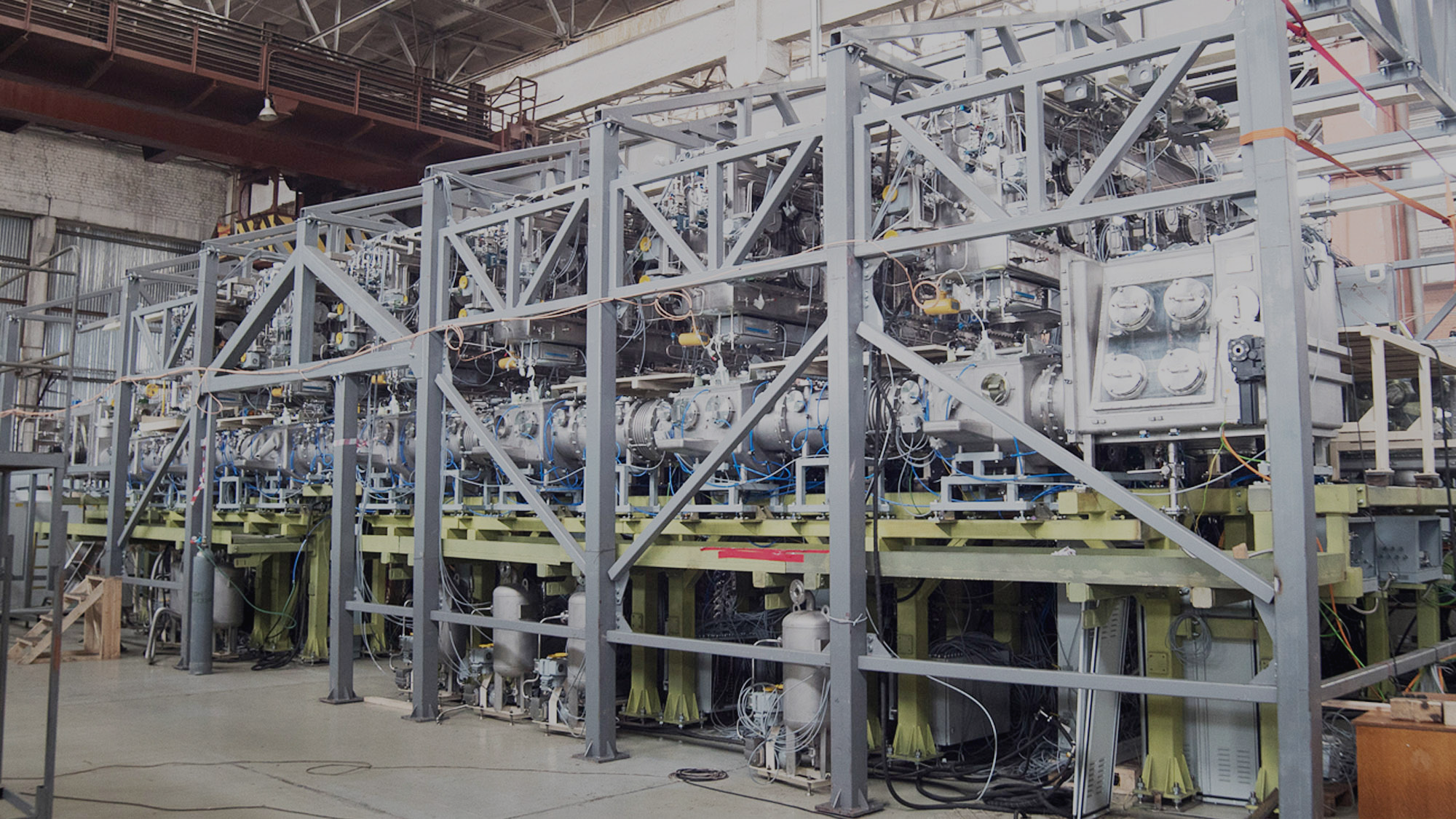

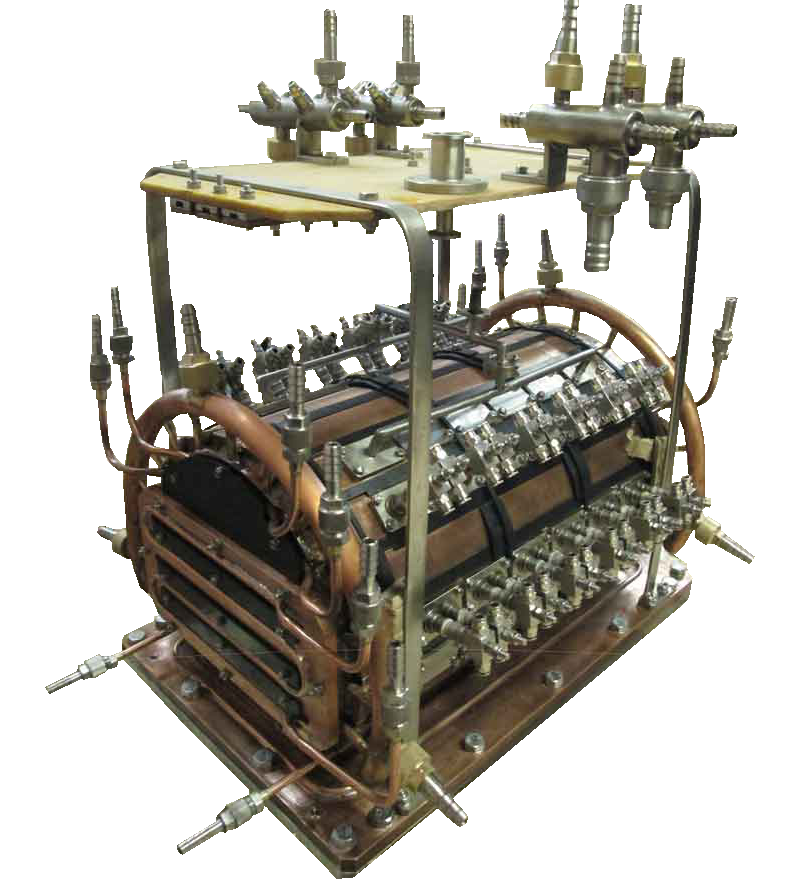

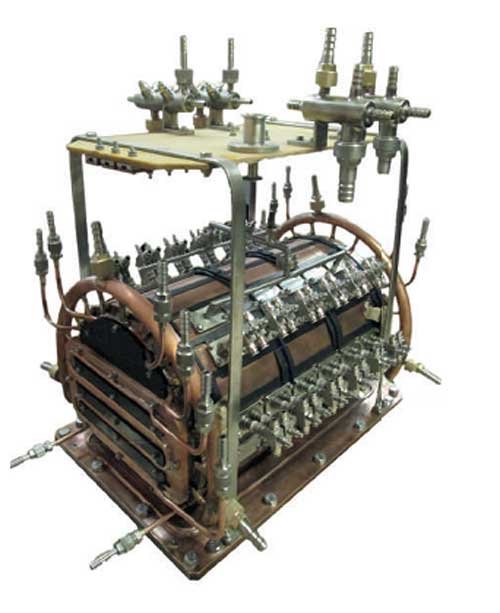

PGBA 918.21.00.000

Designed to increase pressure of the operating gas before its injected into technological hardware.

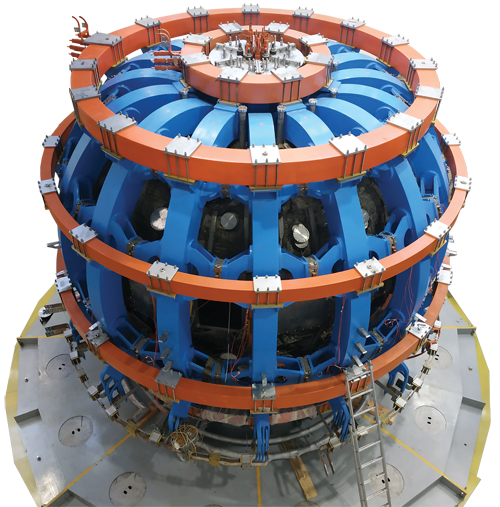

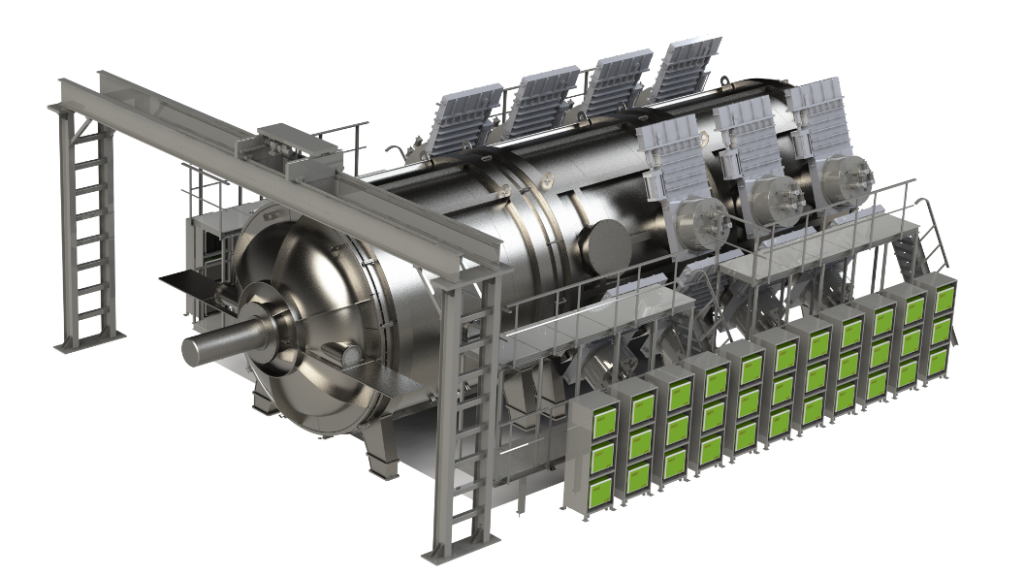

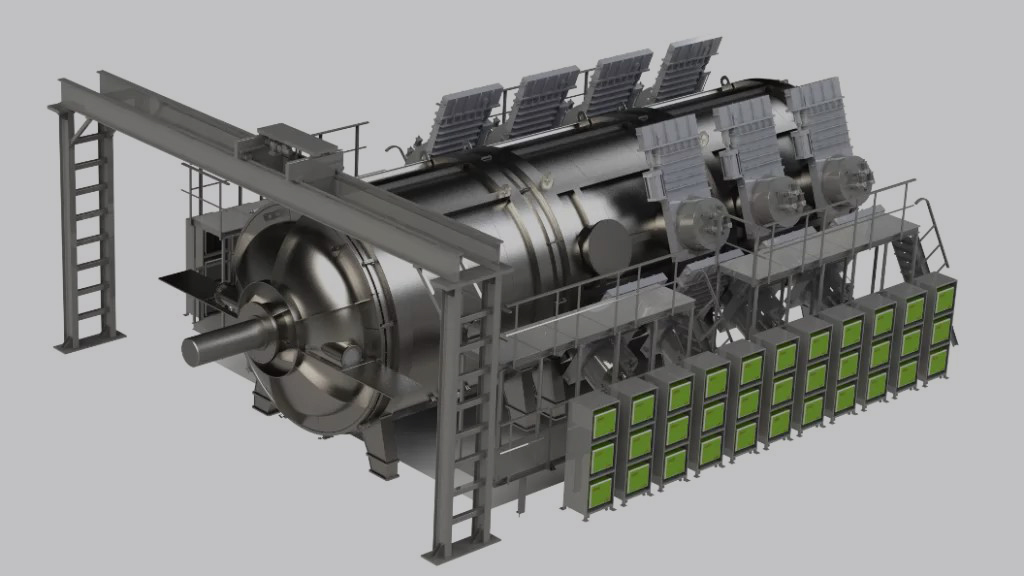

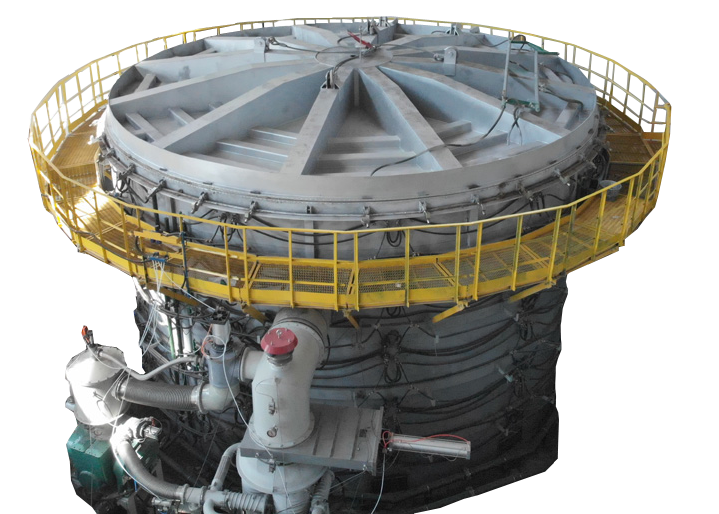

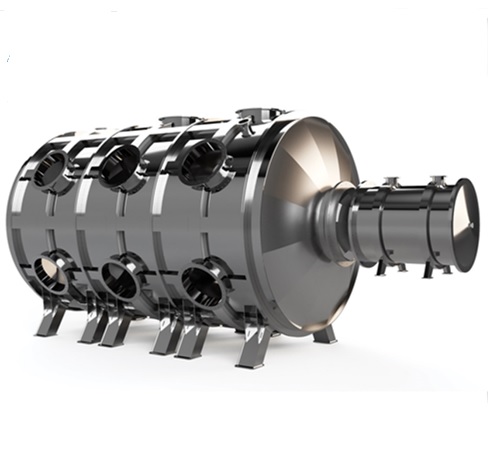

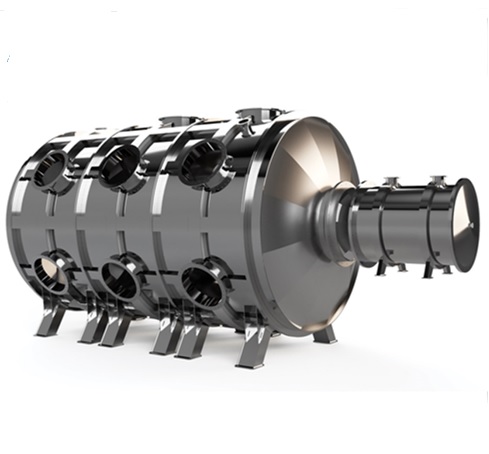

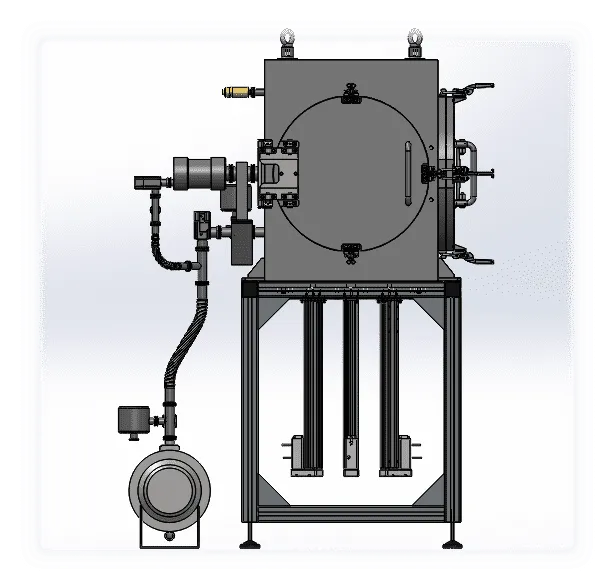

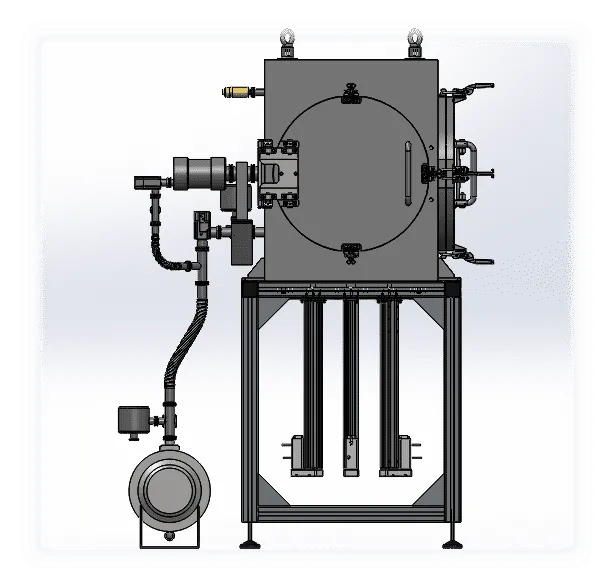

Thermal vacuum chamber is designed to perform out gassing of objects, to manufacture honeycomb panels for spacecrafts (hereinafter referred to as S/C) and perform leak test of S/C modules.

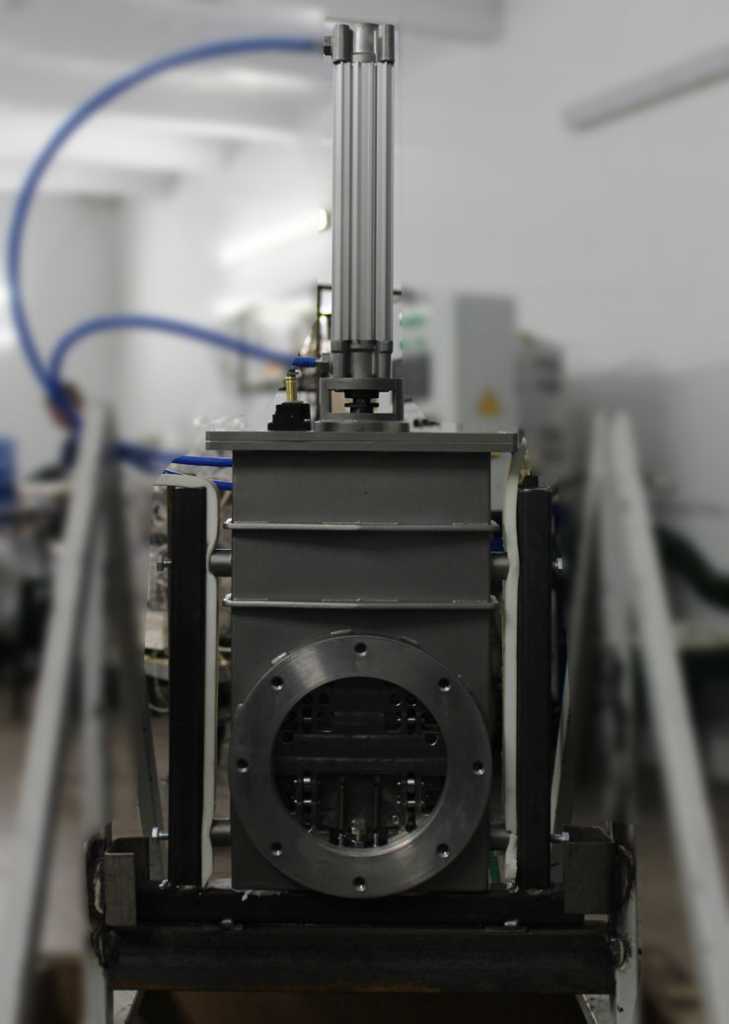

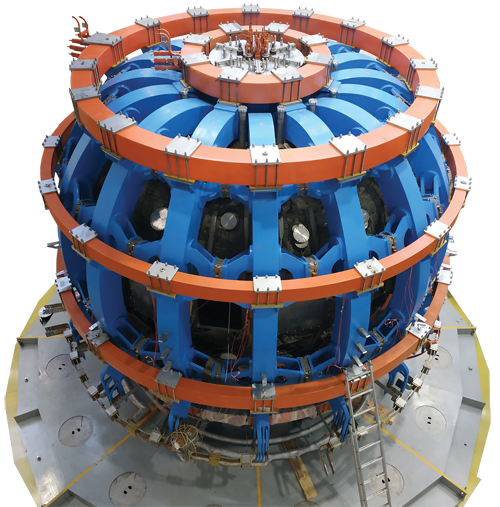

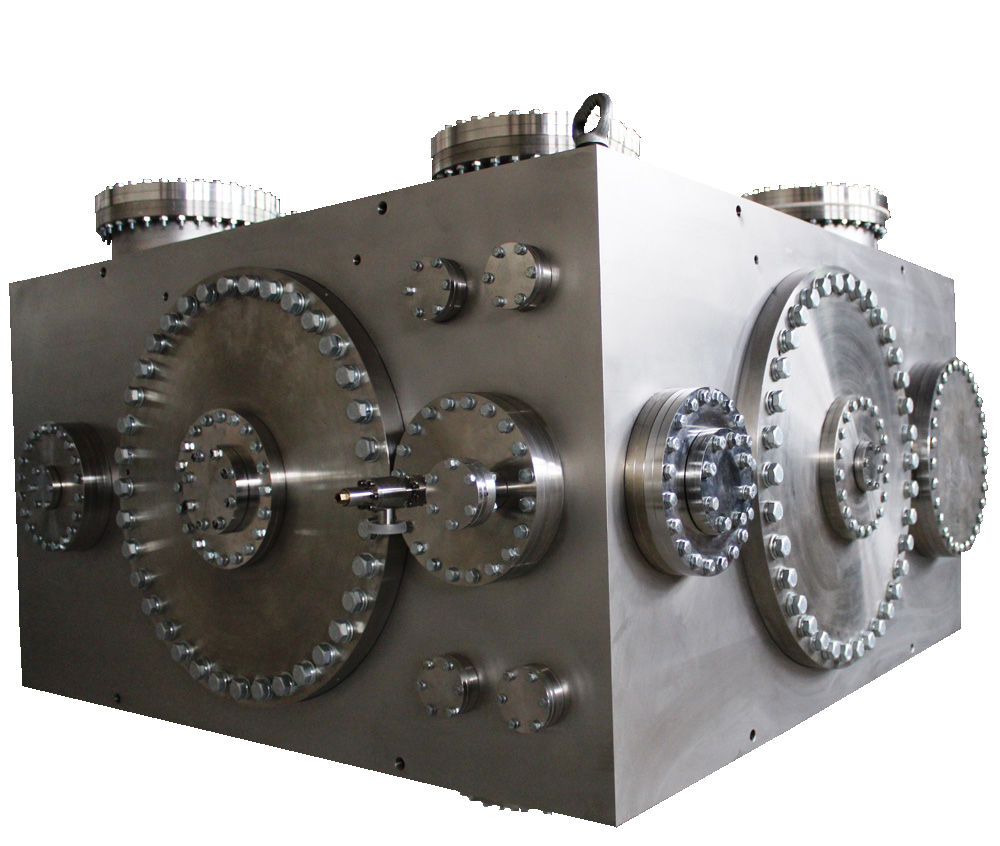

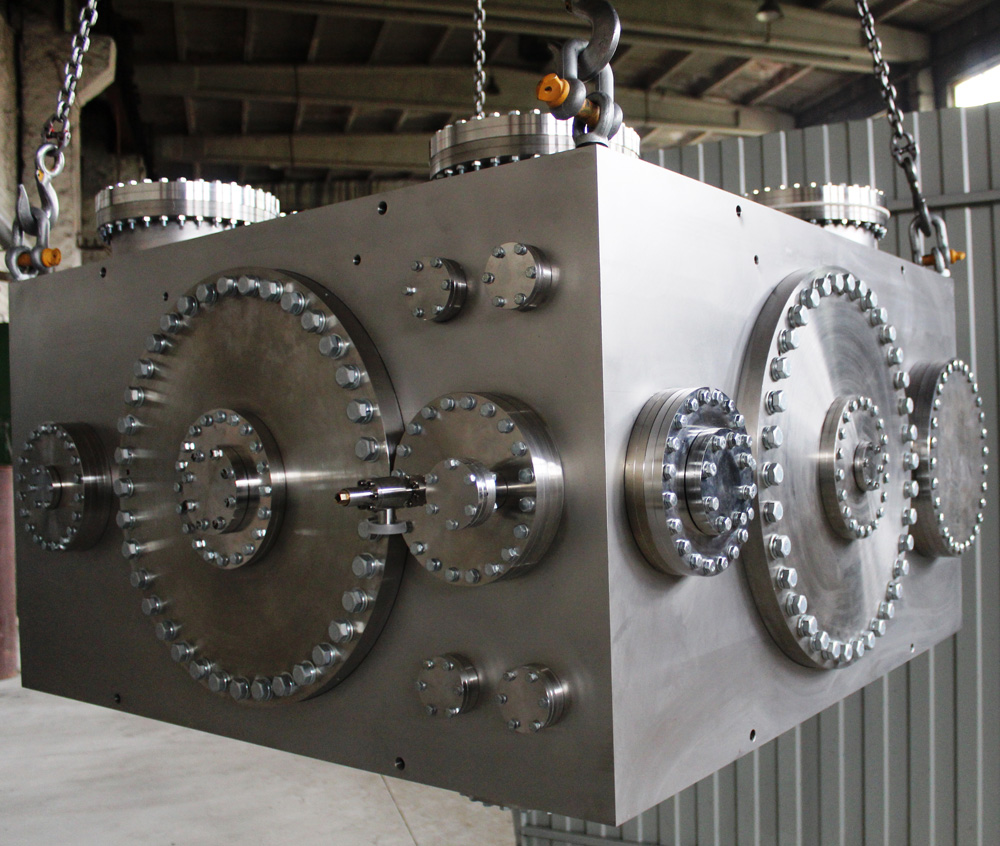

High vacuum rectangular chamber is designed to maintain the operating pressure at the level of 10-9 mmHg (1,3*10-7 Pa) and research of solid-state physics.

Vacuum equipment and special purpose hardware

Recent science and industry in most cases cannot do without vacuum equipment as it ensures the proper vacuum and enables reaching technical goals. Such equipment is of special purpose resulting in improved product quality, enhanced efficiency and energy saving processes thus paving the way towards new technologies.

The “NPO “GKMP” LLC is scientific and production community that aims at engineering and manufacture of special technological and high-tech equipment. We have vast production capacities to produce vacuum equipment and special-purpose hardware.

Advantages of vacuum equipment

Such equipment has a number of benefits considered decisive to use them in different industries with the following categories to be noticed:

- Operational flexibility. Vacuum system can be used in different industries for many applications.

- Enables to perform activities that cannot be performed at standard atmospheric pressure.

- Helps to boost some processes necessary within the production cycle.

Our company is a renowned manufacturer of high quality vacuum hardware. We can manufacture customized hardware per required characteristics for further industrial and scientific application.

Application areas

This type of equipment is used for scientific and research purposes, as well as in other industries, namely:

- In chemical industry to produce different substances;

- In nuclear energy to create vacuum medium for research purpose;

- In electronics and electric hardware to produce high clean materials;

- In medicine to ensure constant operation of institutions and hospitals;

- In biology to perform a number of laboratory studies;

- In food production to pack ready-made items thus increasing their shelf life;

- In mining to remove aggressive medium and transport materials.

This list clearly shows that today’s industry is in dire need of vacuum facilities to meet the vast number of needs.

How we work

Our company manufactures state-of-the-art high quality hardware. We have an extensive team of highly qualified engineers and designers that provide a wide range of services. Cooperation with our company takes several steps:

- Submission of request to manufacture a vacuum facility.

- Filling in the assignment form with required information. We will come back to you at our convenience and make an appointment.

- Please provide the entire information regarding the project: goals, capacities, etc.

- Our experts will prepare all the necessary technical documentation and get the required approval.

- The production of special-purpose equipment will be performed in accordance with the design documentation. All production stages will be subject to thorough control.

- Set-up and testing of the hardware per requirements and parameters enlisted. Efforts to ensure ideal performance at the company’s premises. The facility can be assembled at site and further delivered to the object.

- Off-the-shelf hardware is handed over to the Customer with enabled warranty and post-warranty maintenance.

Our company considers all specific features of vacuum equipment applications. We successfully completed many large-scale projects and cherish our positive reputation. We have all the required licenses, permissions, patents and other documents that confirm high quality of our production.

If you have any more questions regarding the state-of-the-art vacuum hardware, please contact us via contact details given on our website or using the feedback form. We will provide any necessary information at your convenience.