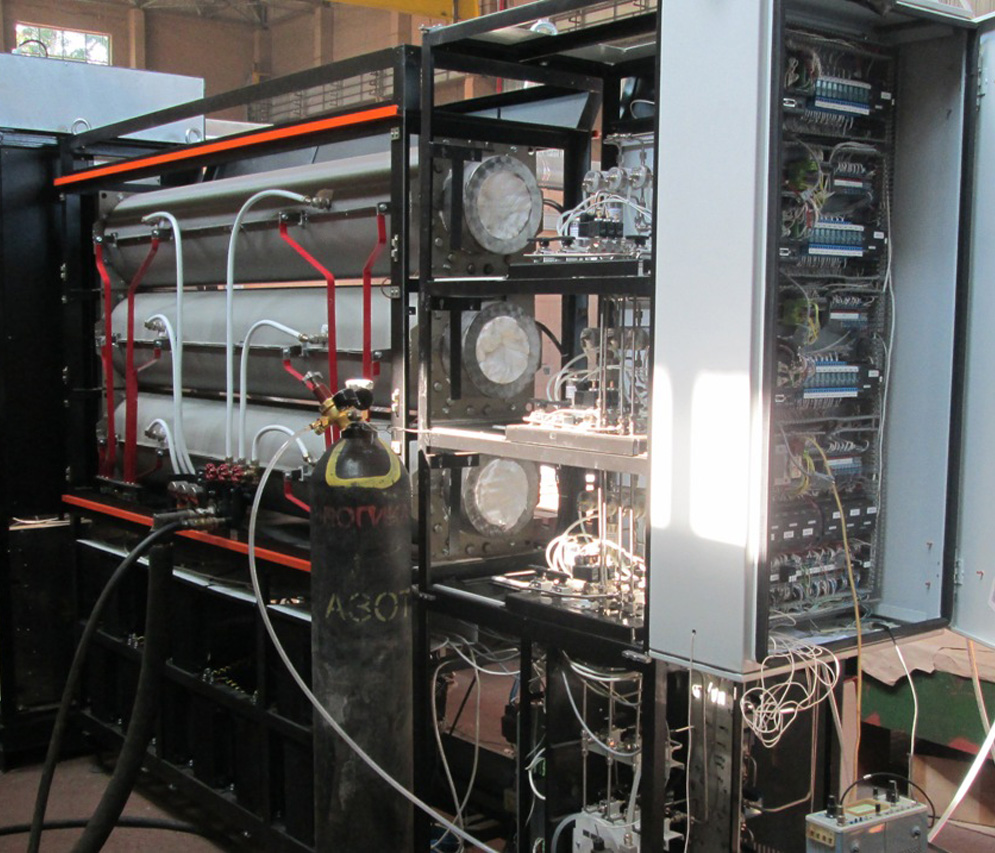

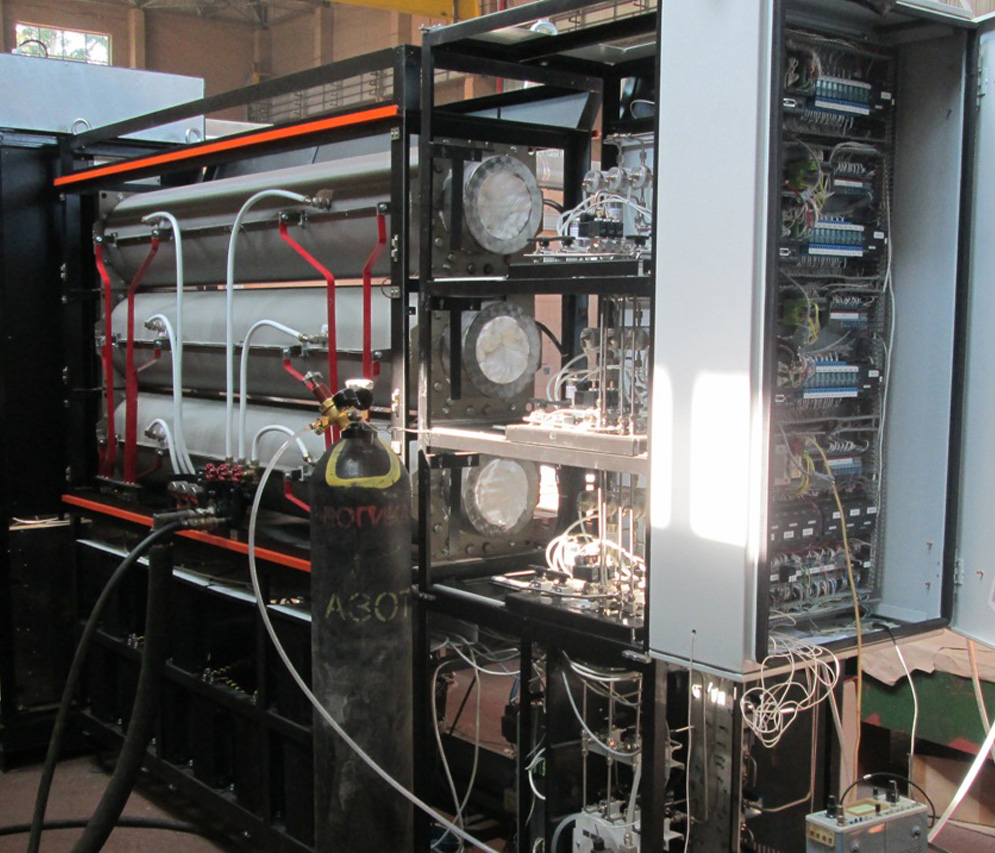

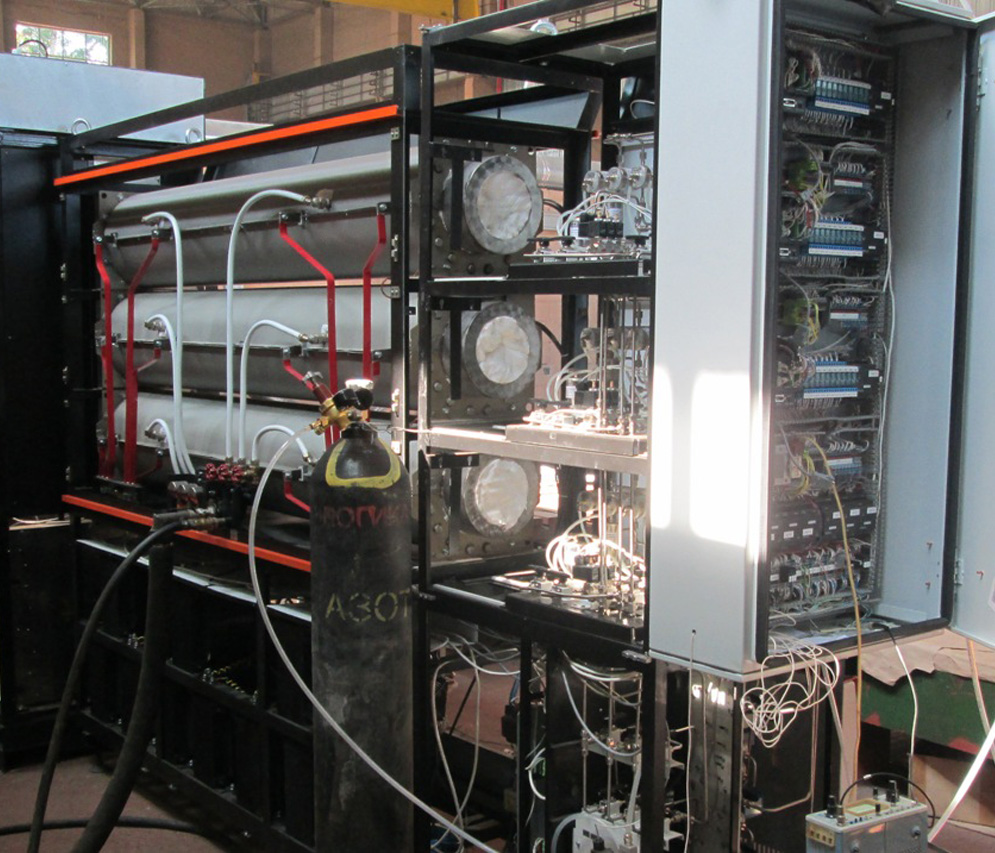

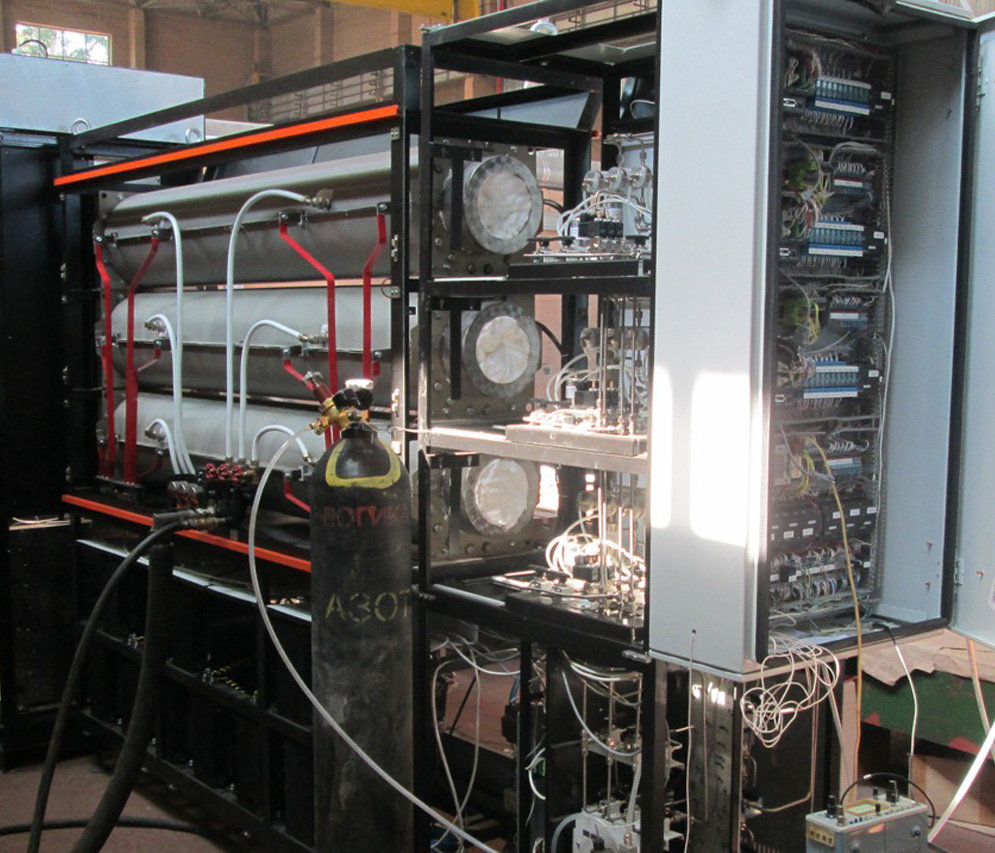

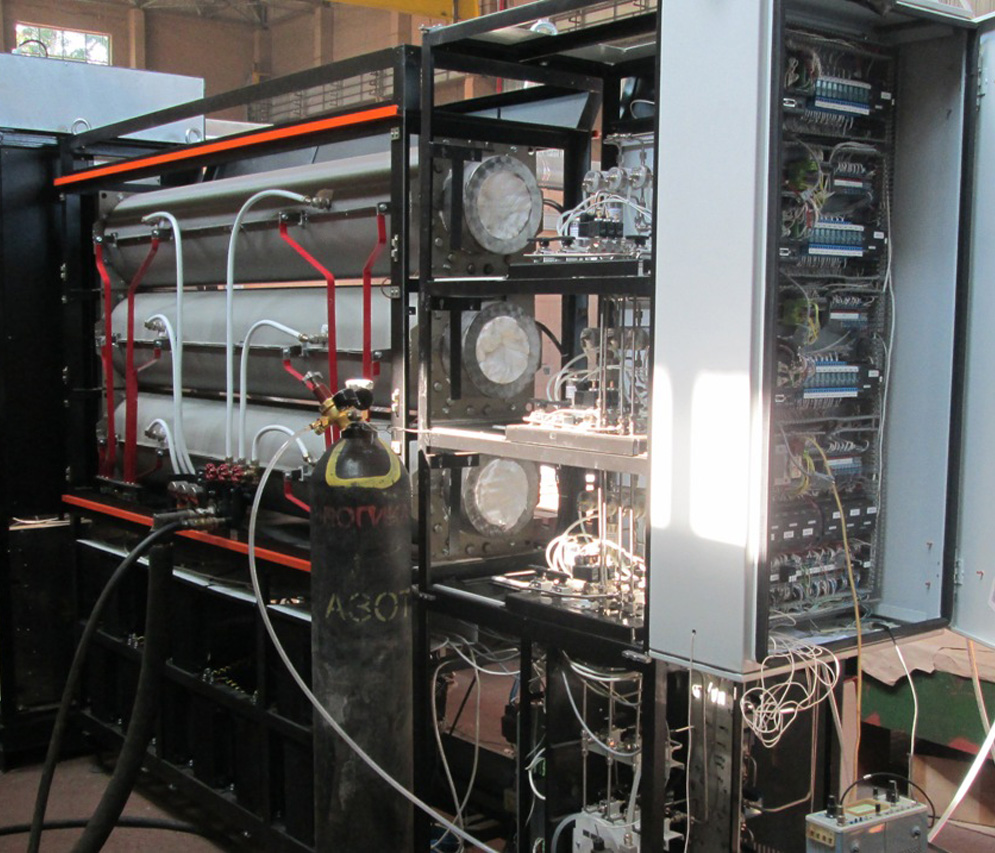

Thermaldiffusion and thermocompression equipment

Thermaldiffusion is a physicochemical process that changes the surface structure of a workpiece under conditions of thermal stabilization and a controlled atmosphere. Thermocompression welding is the process of welding parts from dissimilar materials, carried out with heating under pressure.

Benefits of thermaldiffusion and thermalcompression furnaces

When obtained in thermal compression furnaces, the coating has good adhesion and robustness thus ensuring proper protection from corrosion.

Thermal diffusion process does not take much time, so one can treat a large number of workpieces at time.

The coating is highly robust and resistive to wear-off contributing to the workpieces’ lifetime.

Thermal compression takes place at relatively low temperatures to avoid destruction of metal.

Thermal diffusion does not involve any toxic substances and completely safe for human health and environment.

Thermal diffusion and thermal compression furnaces are facilities widely used in different industries, including metallurgy, metal processing, chemicals and production of plastics.

Thermal diffusions is a physic-thermal process that alters the surface structure of a workpiece treated via thermal stabilization and controlled atmosphere. Thermal diffusion furnace is used to coat metallic parts, such as steel, aluminum and copper by diffusing the metal or chemical compound on the surface of a workpiece. This process can improve corrosion resistance, wear-resistance, strength and other characteristics of a given material. While processing the workpiece is placed in the furnace to be subject to high temperatures and diffusion. Thermal compression, on the other hand, is a physic process that comprises heating of one or few workpieces by applying regulated force that boosts a specific physical process.

On the other hand, thermal compression furnaces are used to compress thermal plastic materials, such as plastics, to create workpieces of different shapes and dimensions. The target material is heated till it reaches the melting point, then the pressure compresses it in the mold thus creating a robust and reliable end piece. Both furnaces are based on the principle of heat transfer from source to material subject to treatment in order to ensure the required conditions for diffusion or compression.

Thermal diffusion furnaces and thermal compression furnaces are important facilities for different industries that may ensure a wide number of functional or protective coatings for metallic pieces and create unique shapes from thermal plastic materials.

Why choose us? Industrial thermal equipment

Get your catalog of industrial thermal equipment