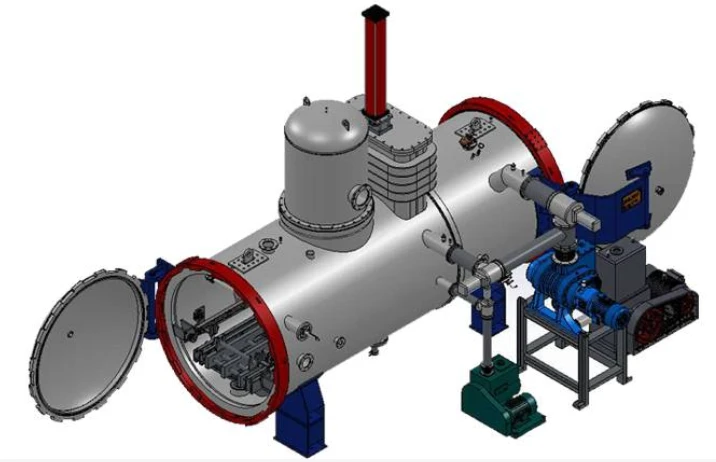

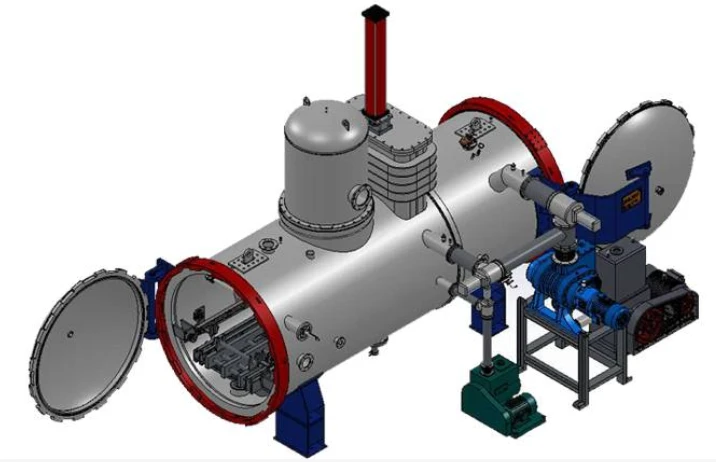

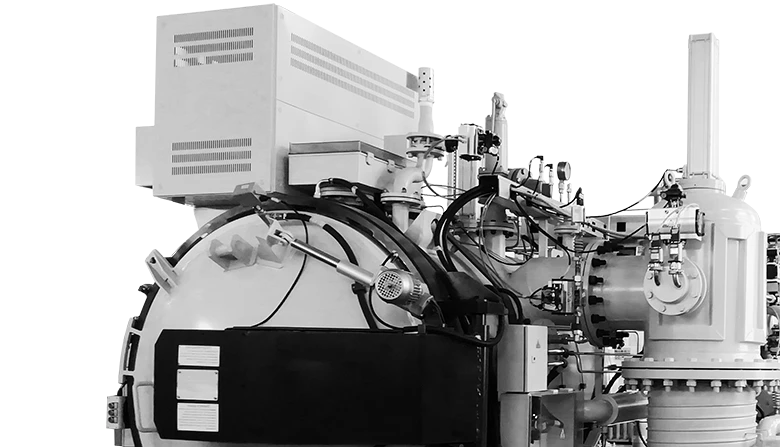

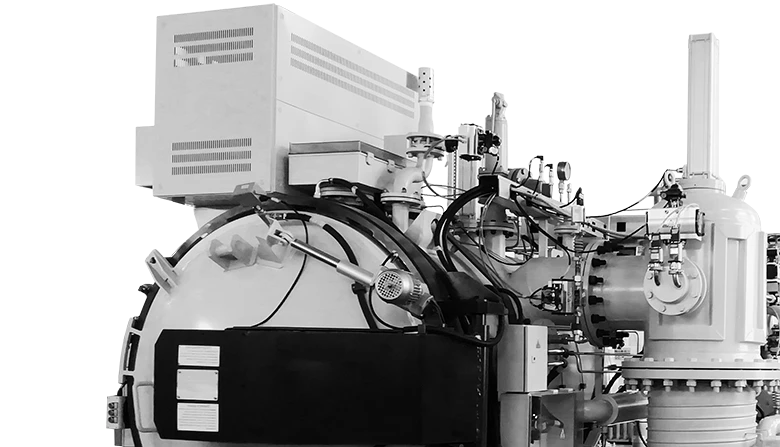

Vacuum furnaces

Vacuum furnaces are specialized thermal equipment that is used to carry out temperature treatment processes in an oxidizing environment and (or) vacuum. Industrial vacuum furnaces are used for heat treatment and melting of various materials.

Some of the main characteristics of vacuum furnaces produced by the “NPO “GKMP” LLC include:

A wide range of device-enabled thermal treatment.

High quality industrial vacuum furnaces designed for continuous lifetime and minimal maintenance.

Vacuum furnaces are equipped with safety systems to prevent overheating and other hazardous situations.

Vacuum furnaces consume less energy in comparison with those operating at atmospheric pressure.

This is achieved via uniform heating and cooling of pieces inside the furnace thus ensuring required properties of materials.

Vacuum inside the furnace prevents the materials treated from oxidation thus improving the quality.

Vacuum furnaces operate at cryogenic temperatures (close to the absolute zero), as well as at extreme ones over 3000 C°.

Vacuum furnaces can support the required temperature down to fractional degrees.

Vacuum furnace is specialized thermal equipment designed for thermal treatment in non-oxidizing media and (or) in vacuum. Industrial vacuum furnaces are used for thermal treatment and melting of different materials to ensure high temperature control. Considering its capacity to work at very high or very low temperatures, vacuum furnaces are perfect choice for a wide range of applications.

Industrial vacuum furnaces are a perfect solution where production of such electronic components as semiconductors and integral circuits are concerned. This equipment is also used in scientific research, metallurgy and glass production. Vacuum furnaces are used to manufacture parts for aerospace industry, in medicine, machinery, automobile production, metallurgy, electronics, and chemical industry. Vacuum furnaces are used to perform sintering of ceramics and metallic powder.

The “NPO “GKMP” LLC is a renowned expert of selection, design and engineering of a wide range of vacuum equipment, including furnaces for sintering metallization paste into ceramics, creation of glass and metal fused junctions, furnaces for tempering and removal of binder, annealing and tempering furnaces, retort vacuum furnaces, vacuum and compression furnaces, vacuum arc furnaces, vacuum chamber furnaces, vacuum laboratory furnaces, vacuum nitration furnaces, vacuum reduction furnaces, vacuum brazing furnaces, vacuum furnaces with low loading chamber, vacuum resistance furnaces, vacuum sintering furnaces, vacuum binder removal furnaces, vacuum melting furnaces, vacuum electron arc furnaces, vacuum thermal furnaces etc.

Why choose us? Industrial thermal equipment

Get your catalog of industrial thermal equipment