Electric resistance (batch) furnaces

Electric resistance (batch) furnaces is an industrial thermal equipment (furnace) that uses resistive heating to increase the temperature of materials passing through it. It consists of a long channel inside which heating elements (usually made of nichrome or fehral) are located to provide heating.

Main advantages of electric resistance (batch) furnaces:

The furnaces are used for various thermal treatment processes such as heating, quenching, annealing, tempering, drying and others. These furnaces can treat different materials including metals, ceramics, glass, plastic etc.

Furnaces are equipped with automated control systems that enable to control and regulate temperature and heating time.

These furnaces can operate in periodic mode, i.e. when material is loaded and unloaded in and from the chamber.

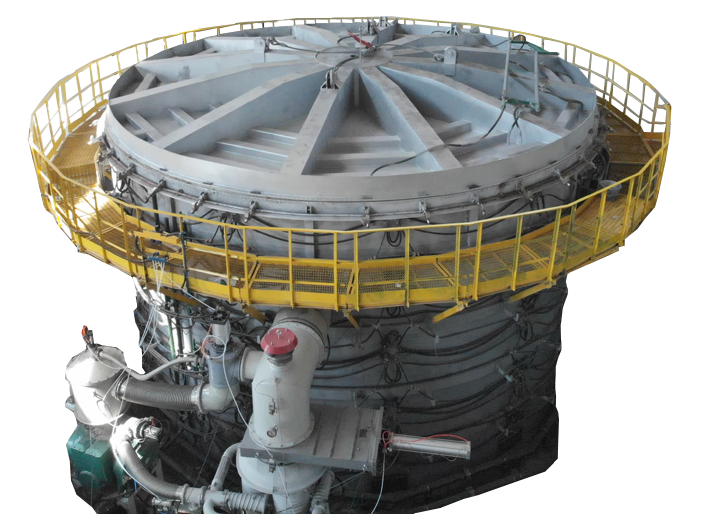

Furnaces have rectangular or cylindrical shape with one or few operating chambers (covers). Heating element located inside the chamber can be manufactured from different materials depending on required temperature and atmosphere inside the furnace.

Periodic resistance chamber furnace is a facility (hardware) designed for contact free transfer of thermal energy from heating element to a heated object in enclosed volume.

The main components of periodic resistance furnace include:

- Furnace body: usually manufactured from heat resistive materials such as stainless steel or cast iron. A heating element is placed inside the body.

- Heating element: coil or tape made from material with high specific resistance (for example, nickel and chromium, ferro-aluminium alloy, chrome-aluminum alloy) that is subject to heating when electric current passes through.

- Thermal couple: designed to measure temperature inside the furnace. Usually located close to the heated material.

- Thermal regulator: device that controls temperature inside the furnace by automatically switching on and off the heating element once the required temperature is reached.

- Control unit: includes regulation mechanisms like power supply switch, temperature regulator and operating indicators.

Periodic resistance furnace is used in many industries such as metallurgy, machinery, chemical industry, production of ceramics and glass. One can perform a wide range of operations, including annealing, tempering, quenching, brazing and fusion of materials.

Why choose us? Industrial thermal equipment

Get your catalog of industrial thermal equipment