Vacuum shut-offs

Modern technologies and a powerful production base ensure a high level of quality in the development and design of unique vacuum equipment, which allows us to achieve technical characteristics that are unattainable for competitors.

The 15-year experience of NPO GKMP LLC in working with clients from various industries has allowed us to develop a large line of special vacuum valves.

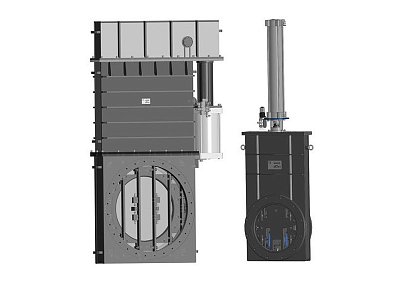

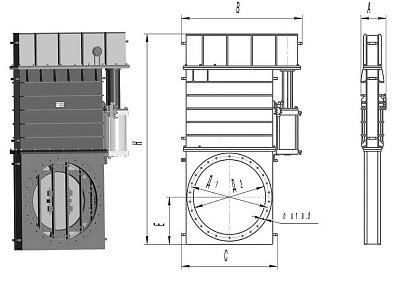

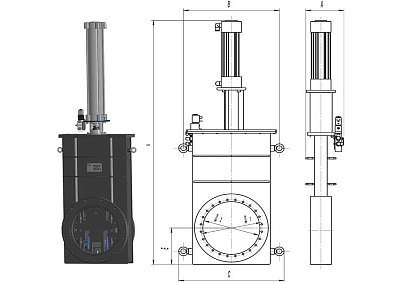

The main components related to the two types of those produced by the NPO “GKMP” LLC are shown on the Picture 1 as an example of a shut-off with a rubber seal.

The housing is a leakproof vacuum chamber attached by the flanges to the vacuum system. Unlike vacuum valves, the gate valve poppet moves perpendicularly to the gas flow thus ensuring its maximum conductivity when opened. This is the reason why vacuum shut-offs are the best to equip the hardware operating in molecular gas mode, like turbomolecular, ion, getter and cryogenic pumps.

Vacuum shut-offs can be operated manually, pneumatically or electromechanically. Shut-offs can be manufactured with bellows or elastomer rod seal.

Housing

Pneumatic cylinder

Support

Housing cap

Poppet

Retainer poppet

Frame

Spring

Electromagnetic shutoff

This product perfectly meets the needs of vacuum flow regulation. The control of the valves is ensured via processing of specific electric signals. Shutoffs are available in various dimensions in order to fit any vacuum system in the best manner.

The main benefit of such a shutoff is instant actuation. The opening takes less than 0.2, the closing – about 0,1. The product has no stand-alone control device and therefore, has better actuation capacity. This is the reason why shutoffs of this type are used for emergency valves.

To the closures

Electromechanic shutoff

This type of shutoffs is second-to-none as when compared with others, they provide better stability and robustness. Such stand-alone mechanism provides no effect whatsoever on how vacuum equipment is to be mounted.

When selecting a proper option, the specific energy type shall be taken into account, as well as required actuation cycle and pass-through diameter. Select manual or automatic control.

Electric pneumatic shutoff

This type of shutoffs is designed to meet kinematic scenarios. Actuation devices start operation induced by forward motion. Such shutoffs are characterized by high actuation speed due to the adopted pneumatic drive that regulates the gas flow in the system.

The “NPO “GKMP” LLC produces vacuum feedthrough shutoffs with pneumatic drive designed to seal vacuum systems.

Application: vacuum systems designed for production of electronics, electric devices, energy, instrumentation, machinery, scientific research.

Shutoffs are equipped with a pneumatic drive. Operating medium – air or non-corrosive gases. Shutoffs are manufactured with flanges of various dimensions per attachment standard ISO-K/ISO-F. Shutoffs are manufactured per NF category 4 of the GOST 15150. Refer catalogue to find the required model.

To the closures

The general appearance of shut-offs with rubber seal and overhead pneumatic cylinder.

Table 1. Dimensions and mass of shut-offs per Design documentation

|

Dу of the shut-off |

Dimensions, mm |

n of mating part |

Mass, kg (not to exceed) |

|||||||

|---|---|---|---|---|---|---|---|---|---|---|

|

H |

B |

E |

C |

A |

D1 |

D2 |

d |

|||

|

Dy 160 |

871 |

300 |

112 |

335 |

139 |

200 |

150 |

М10 |

8 |

30 |

|

Dy 200-1 |

1142 |

367 |

155 |

398 |

143 |

260 |

200 |

М10 |

12 |

60 |

|

Dy 200-2 |

1251 |

364 |

150 |

400 |

144 |

232 |

200 |

М8 |

24 |

50 |

|

Dy 320-1 |

1494 |

476 |

212 |

512 |

173 |

395 |

306 |

М12 |

16 |

100 |

|

Dy 400-1 |

1704 |

5944 |

269 |

641 |

204 |

480 |

400 |

М12 |

16 |

190 |

|

Dy 900-2 |

2530 |

1502 |

569 |

1112 |

- |

980 |

900 |

М16 |

28 |

1510 |

Table 2. Main characteristics of shut-offs.

| Designation |

Shut-off nominal diameter, Dу |

||||||

|---|---|---|---|---|---|---|---|

|

160 |

200 |

320 |

400 |

630 |

900 |

1250 |

|

|

Operating air pressure, bar |

4-6 |

4-6 |

5-6 |

5-6 |

5-6 |

5-6 |

5-6 |

|

Open/closure time, sec |

4/4 |

4/4 |

4/4 |

6/5 |

10/11 |

16/15 |

18/17 |

|

Pressure difference to open a shut-off, MPa (mmHg) (not to exceed) |

0.106 (800) |

0.106 (800) |

0.106 (800) |

0.106 (800) |

0.106 (800) |

0.106 (800) |

0.106 (800) |

|

Helium leak rate, mm Hg•l/sec |

˂1*10-9 |

˂1*10-9 |

˂1*10-9 |

˂1*10-9 |

˂1*10-9 |

˂1*10-9 |

˂1*10-9 |

|

Ultimate operating pressure in the vacuum chamber, Pa (mm Hg), (not to exceed) |

0.067 (5*10-4) |

0.067 (5*10-4) |

0.067 (5*10-4) |

0.067 (5*10-4) |

0.067 (5*10-4) |

0.067 (5*10-4) |

0.067 (5*10-4) |

|

Poppet shall be hermetically clamped to the housing at residual pressure, Pa (mmHg) |

0.067 (5*10-4) |

0.067 (5*10-4) |

0.067 (5*10-4) |

0.067 (5*10-4) |

0.067 (5*10-4) |

0.067 (5*10-4) |

0.067 (5*10-4) |

|

Mounting position |

Vertical Horizontal |

Vertical Horizontal |

Vertical Horizontal |

Vertical Horizontal |

Vertical Horizontal |

Vertical Horizontal |

Vertical Horizontal |

|

Warm-up temperature when the shutoff is open, ºС |

200* |

200* |

200* |

200* |

200* |

200* |

200* |

|

Warm-up temperature when the shutoff is open, ºС |

150* |

150* |

150* |

150* |

150* |

150* |

150* |

Some of the main advantages of ordering vacuum shut-offs from GKMP:

Once shut-offs arrives at the storage site, the person in charge shall perform a number of actions to properly locate the goods as provided by service instruction.

Vacuum shut-off is packed at manufacturer’s premises as required by the Design documentation.

Shelf life is 6 months provided that storage requirements are met.

Storage conditions (1) L per GOST 15150 at the air temperature from +5 to +40ºC and relative air humidity 80% at 25ºC. Shut-offs can be transported with any vehicles. When loaded, a shut-off shall be protected from any mechanical damage, either internal surfaces from contamination. Companies and organizations that use shut-offs in their activity, shall keep those in proper condition and ensure the safe operation strictly in compliance with operational documents.

The proper technical maintenance and use of industrial equipment enable to cut substantially the maintenance costs and off period.

Vacuum shut-offs are manufactured and packed at the manufacturer company’s premises per requirements of the Design Documentation.

Vacuum shut-offs are manufactured and packed at the manufacturer company’s premises per requirements of the Design Documentation.

The Manufacturer (Supplier) guarantees that shut-offs correspond to requirements of relevant technical conditions and regulatory documents provided that User complies with required conditions of transportation, storage, mounting and use.

Warranty life time of a shut-off is 112 months once commissioned. Warranty shelf life is 6 months. Warranty does not cover cases when the user does not comply with the storage rules, improper mounting and use of the shut-off.

Vacuum closures

<1*10-9

Get your catalogue of Vacuum hardware and customized equipment