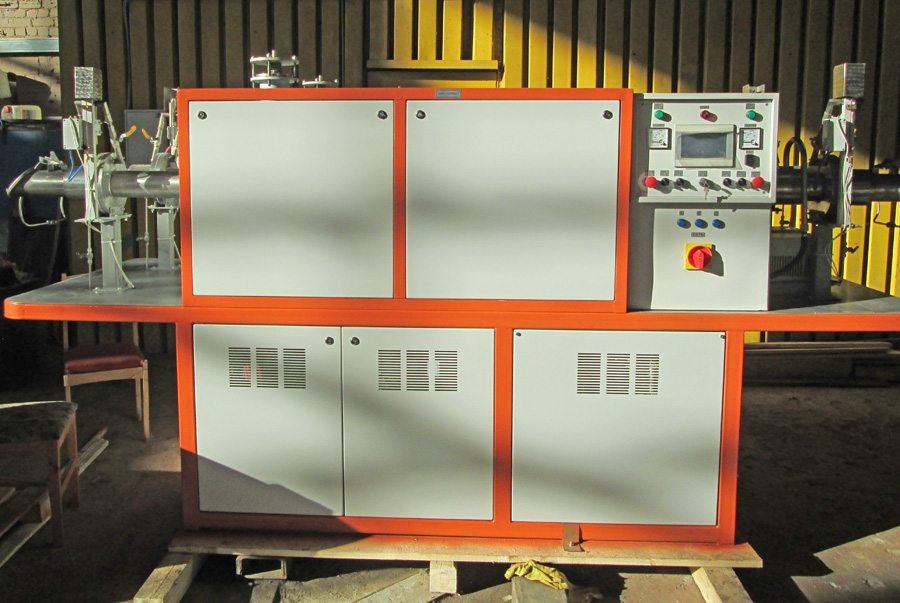

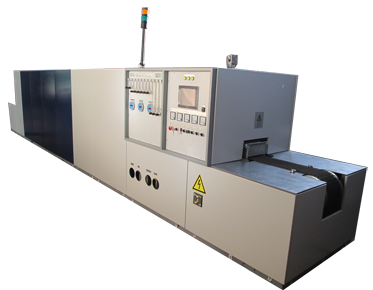

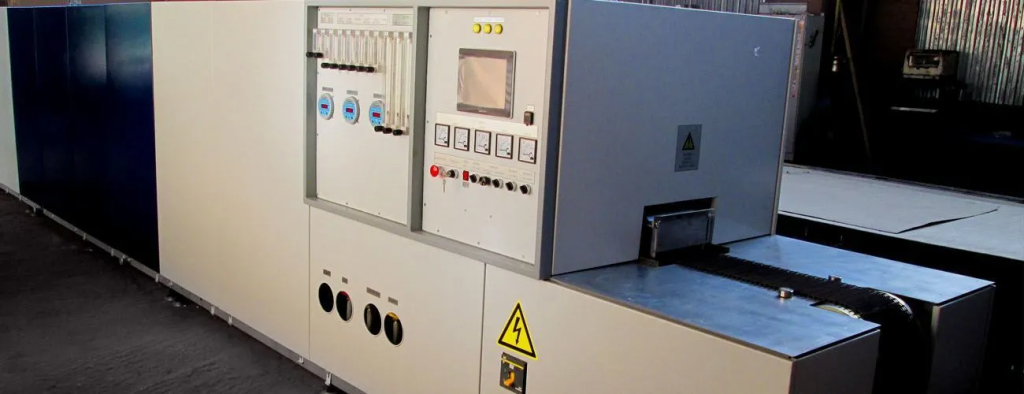

Electric conveyor continuous furnaces

Electric resistance furnace of through-feed type is an industrial thermal facility (furnace) based on resistive heating to increase temperature of materials involved. It consists of a long channel with heating elements located inside (usually made from nickel-chromium of ferrous-aluminum).

Resistance furnaces of through feed type have a number of benefits:

Enables to select the best solution for each specific process.

Ensures robustness and long service life.

Can be ensured via integration of furnace in product line or control system.

High energy efficiency, as heating elements are in direct contact with heated material; this approach decreases heat losses in environment.

Chamber electric furnaces are used in different industries, namely:

- Thermal treatment of metallic parts, including tempering, quenching, stabilization and annealing

- Soldering works

- Drying and sterilization of food products and other non-metallic materials

- Burning of powder paints and glazers

- Melting of materials and alloys (in case of high temperature furnaces)

- Sintering of galvanic coating in hydrogen shielding and reducing ambient at given temperature

The main disadvantage of through-feed type resistance furnace is the need of constant temperature and speed control of material fed inside the furnace in order to ensure a uniform and stable heating. Apart from that, such furnaces can take a lot of space at production site due to their length.

The “NPO “GKMP” LLC provides through-feed type electric resistance furnaces of non-standard dimensions per Customer’s specification.

Why choose us? Industrial thermal equipment

Get your catalog of industrial thermal equipment