Tungsten

Tungsten is a valuable and rather rare refractory metal, which due to its unique characteristics is actively used in a number of industries. Tungsten has the highest melting point and lowest vapor pressure of all metals, and at temperatures over 1650°C has the highest tensile strength.

It has excellent corrosion resistance and is attacked only slightly by most mineral acids. Along with an increase in temperature, the ductility of tungsten increases while maintaining the strength characteristics. Tungsten processing is carried out only at high temperatures, under ordinary conditions this material is quite brittle.

Benefits of tungsten items

The maximal operation temperature: in oxygen-free shielding and reduction medium up to 2600 °C.

Thermal conductivity and red-hardness: tungsten keeps its properties intact once heated up to full red and at subsequent cooling down.

Creeping and rupture strength (much higher than that of molybdenum, tantalum, niobium at, for example 1110°C).

Chemical inertness: up to 400°C in oxygen, up to 600°C in hydrogen, up to 700°C in ammonium and up to 800°C in nitric oxide.

Tungsten products have high density – 19.3 g/cm3, hardness (HV30 >460).

Tungsten products have the highest melting point among refractory metals - 3420 °C.

Thanks to its extraordinary refractory properties and high strength tungsten is considered as the most promising base for materials and pieces expected to operate at high temperatures and radiation. Low electric resistance, thermal expansion and electron emission render tungsten irreplaceable material best fit for high temperatures. Apart from that, tungsten pieces are used in highly aggressive medium without being subject to any deformation or rupture whatsoever.

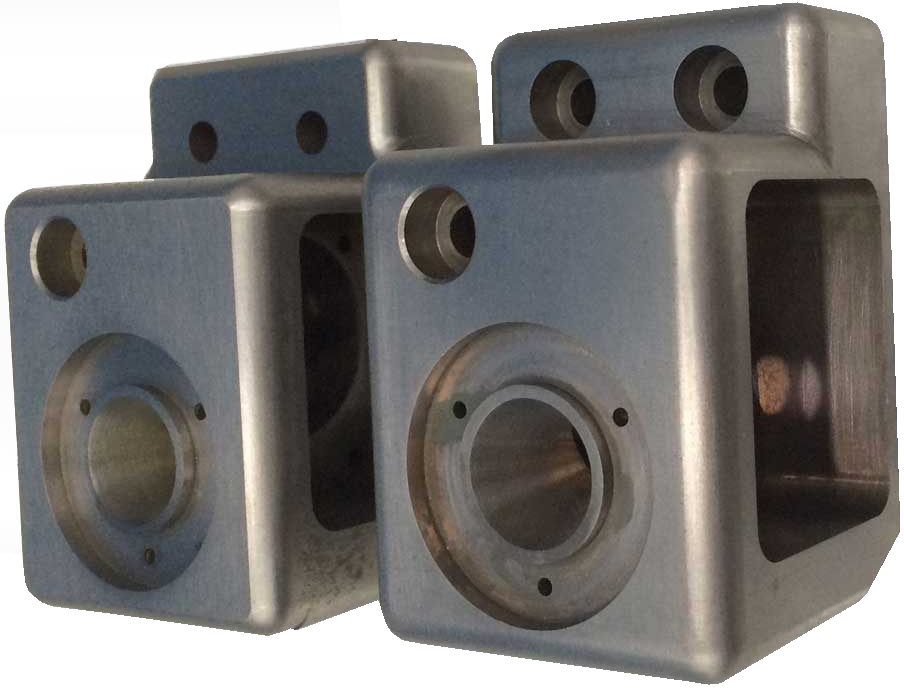

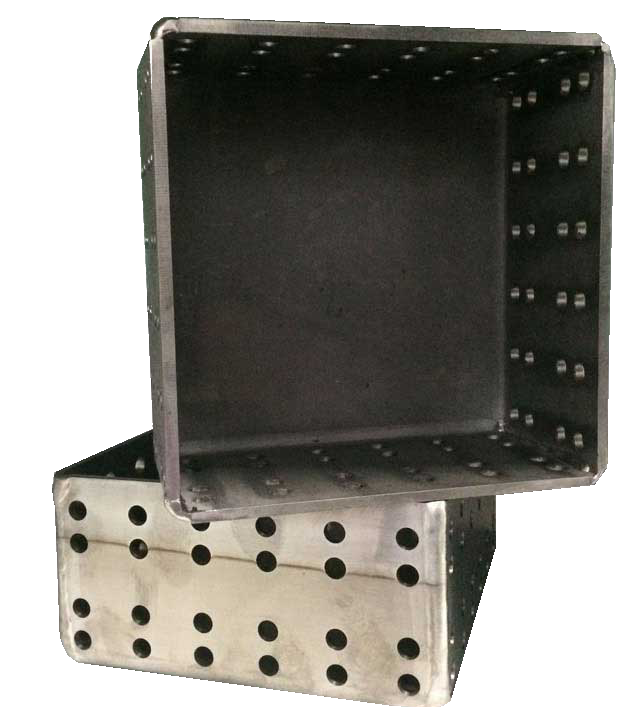

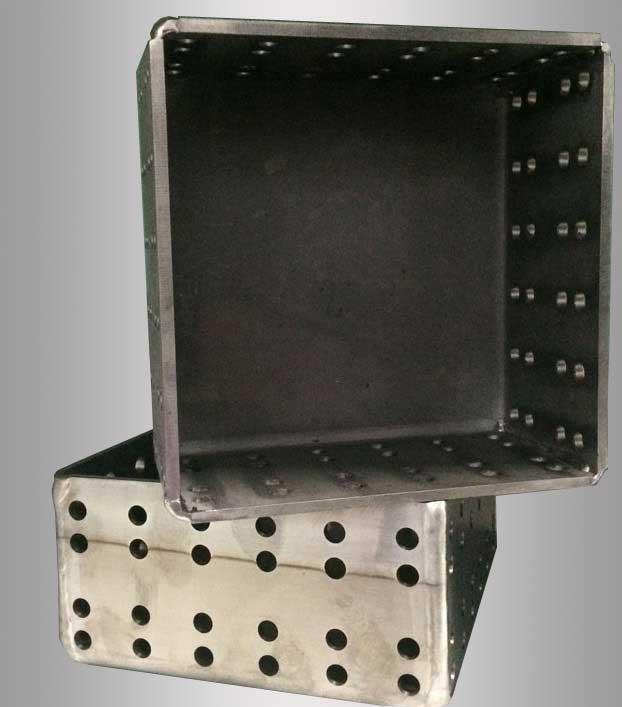

Parts made of tungsten alloys are peculiar with its durability, strength and high quality. Our company mastered a unique production technology of tungsten jig by welding.

Application

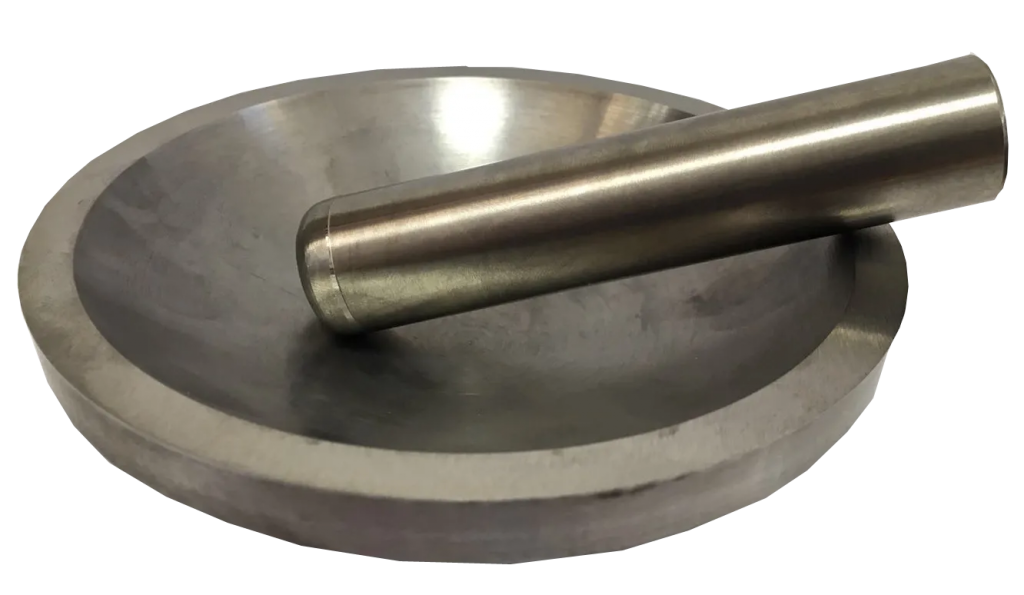

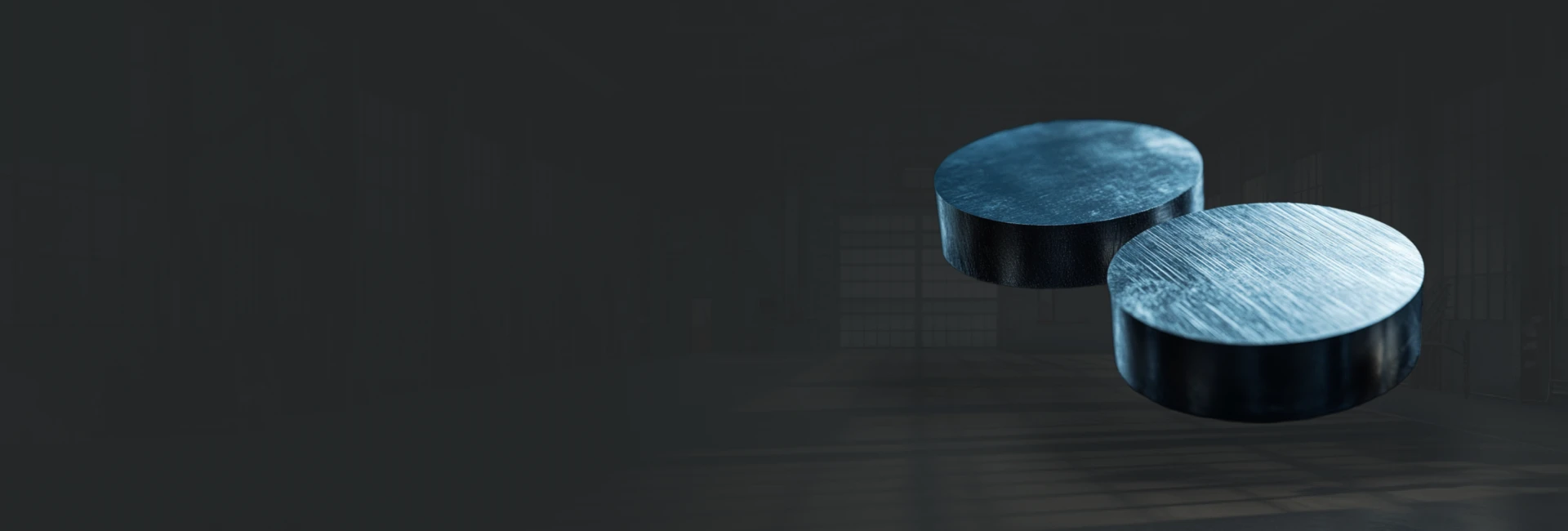

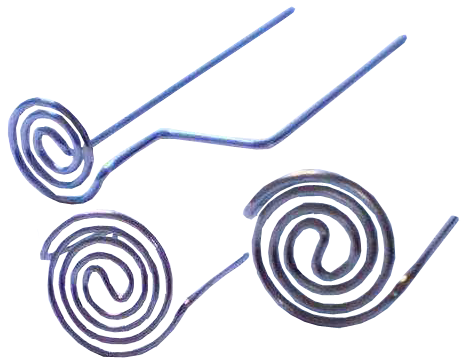

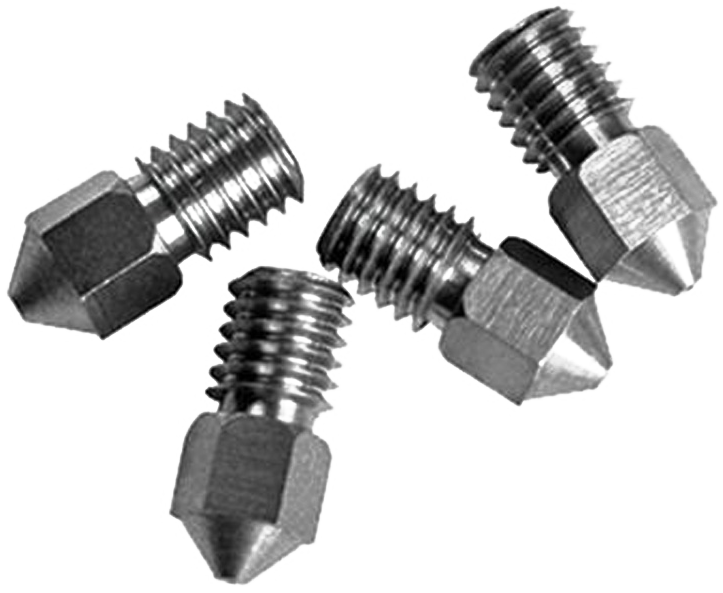

Tungsten and tungsten-based alloys are widely used to produce crucibles, shrouds, heaters, different pieces, parts of electric vacuum furnaces and other units designed to operate at high temperatures:

- As jig for high temperature hydrogen and vacuum furnaces;

- For cathode production: as the base for infusible welding electrodes;

- For glass production (fusible electrodes and tungsten stirrer);

- For pressing of hot metals;

- For production of heat resistive parts of space rockets;

- As shrouds to decrease radiation emission flow in nuclear energy etc.

Why choose us? Items manufactured from refractory metals and alloys

GET YOUR CATALOGUETEST