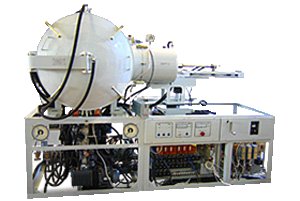

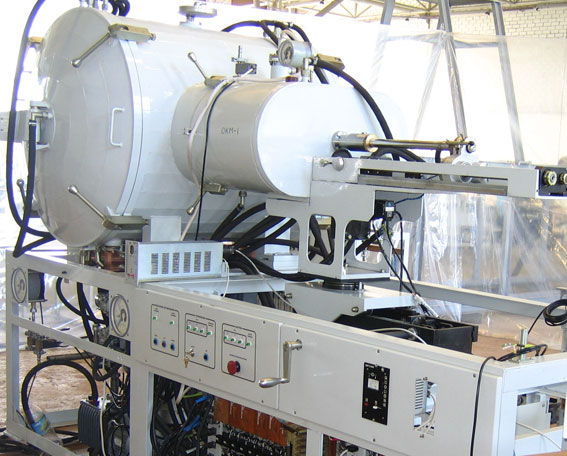

Machines for growing of sapphire and ruby monocrystals per Bridgman-Stockbarger method

This facility is designed to grow leucosapphire and ruby monocrystals of any crystallographic orientation, including the C-orientation (0001). A monocrystal is grown in a crucible, the form and dimensions of which shape those of the final crystal. The Bridgman-Stockbarger method is applied to grow crystals of any crystallographic axis resulting in better yield and reduced costs of further machining.

More

*On request

We will tell you in detail about our products, types and cost of delivery, prepare an individual offer and develop a technical specification

Description

Specifications

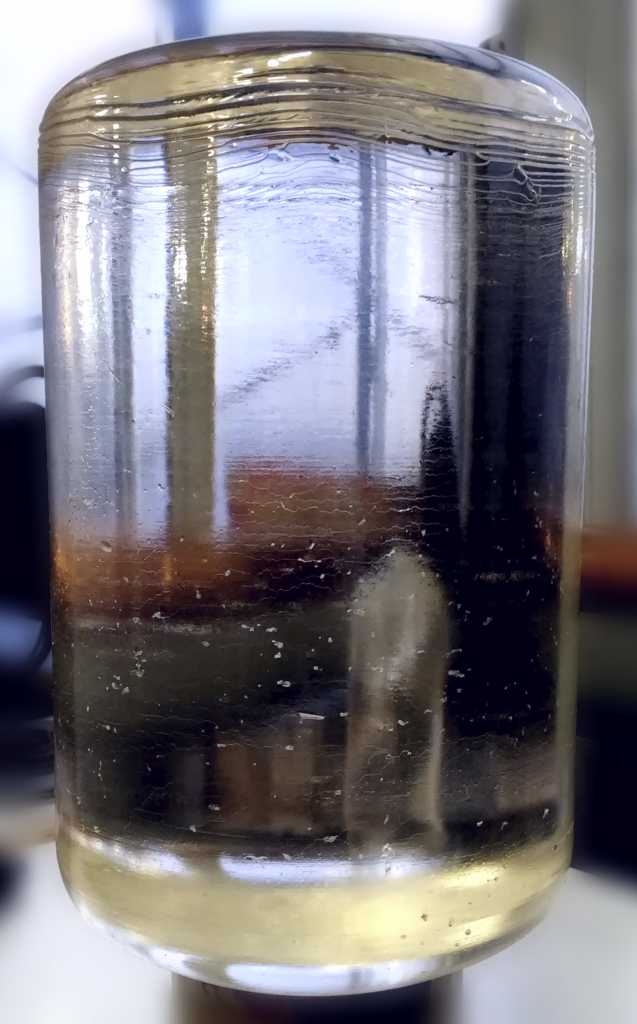

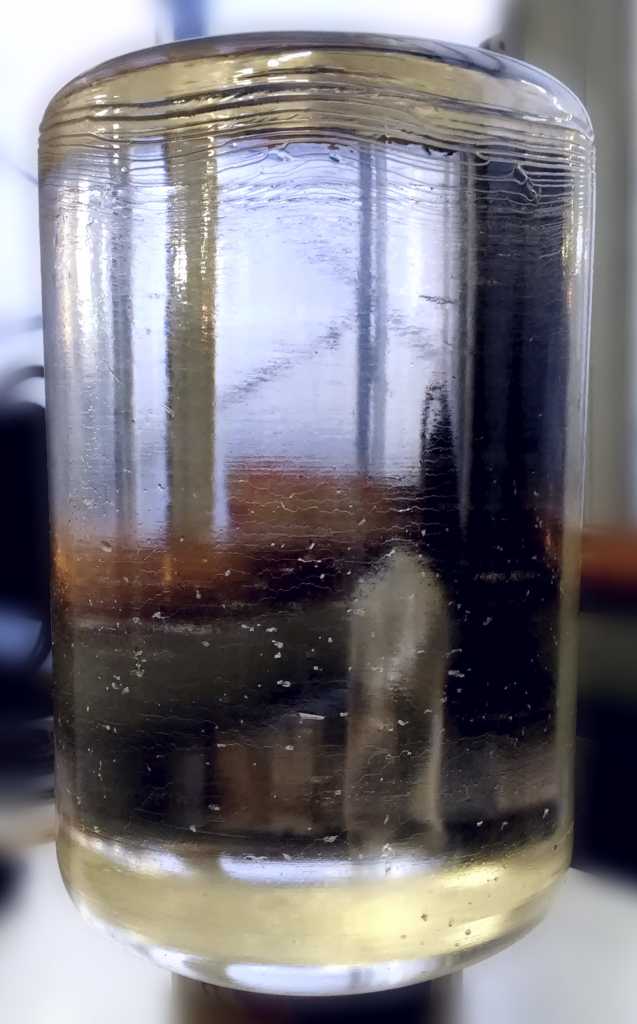

A monocrystal is grown in a crucible, the form and dimensions of which shape those of the final crystal. The seed is placed in the lower part of the crucible; the melting degree serves as a direct indicator of whether it is possible to initiate the growing process of the crystal. The required axial temperature gradient is defined both by the thermal node itself and by the crucible moving towards the cold area thus ensuring the proper heat dissipation and high temperature gradient along the crystal axis.

As long as Bridgman-Stockbarger methodoperates in bottom-up direction, bubbles and impurities are removed from the crystal by the crystallization front. This technique enables to grow crystals at higher speed with less pinhole defect and bubbles.

The crucible with the crystal can be rotated at speed of 5…30 rpm. The rotation is used to balance thermal conditions inside the crucible; at the same time, the centrifugal force pushes impurities and bubbles closer to the walls of the crucible.

Growing of rubies requires well-prepared raw material. To achieve this goal the powder Al2O3 is thoroughly mixed with alloying element Cr2O3. Then the created mixture is pressed in tablets 5…10 mm via tableting machine. This machine can be ordered with the entire facility.

The facility is equipped with the leak proof gas extraction system to relieve the gas from the chamber prior to any opening. The hardware is manufactured on request under approved Technical assignment. Any parameters can be changed at your convenience.

As long as Bridgman-Stockbarger methodoperates in bottom-up direction, bubbles and impurities are removed from the crystal by the crystallization front. This technique enables to grow crystals at higher speed with less pinhole defect and bubbles.

The crucible with the crystal can be rotated at speed of 5…30 rpm. The rotation is used to balance thermal conditions inside the crucible; at the same time, the centrifugal force pushes impurities and bubbles closer to the walls of the crucible.

Growing of rubies requires well-prepared raw material. To achieve this goal the powder Al2O3 is thoroughly mixed with alloying element Cr2O3. Then the created mixture is pressed in tablets 5…10 mm via tableting machine. This machine can be ordered with the entire facility.

The facility is equipped with the leak proof gas extraction system to relieve the gas from the chamber prior to any opening. The hardware is manufactured on request under approved Technical assignment. Any parameters can be changed at your convenience.

Benefits of machines for growing of sapphire and ruby monocrystals per Bridgman-Stockbarger method produced by the “NPO “GKMP” LLC

- Growing per any crystallographic axis, including C-axis (0001)

- Automatically driven process, including seed placement

- TV cameras, pyrometers or thermocouples are not required

- Highly qualified operators are not required

- The furnace requires just maintenance: removal of the crystal, furnace cleaning, loading of raw material

| Property | Meaning |

|---|---|

| Crystal diameter, mm, not to exceed | 160 |

| Crystal length, mm | 250 |

| Crystal mass, mm | 24 |

| Internal chamber diameter, mm | 800 |

| Chamber height, mm | 1100 |

| Ultimate vacuum inside chamber, torr | 5*10-5 |

| Internal gas over pressure (Ar, N2, CO2), kg/cm2 | 1.0 |

| Travelspeed (melting sensor), mm/min | 50 |

| Stroke (melting sensor), mm | 720 |

| Crucible. Travel speed (operating), mm/h | 0.1…10(±1%) |

| Crucible. Travel speed (accelerated), mm/min | 50 |

| Crucible. Stroke, mm | 400 |

| Crucible. Rotation speed, rpm | 1…30(±1%) |

| Crucible. Max load to the rod, kg | 300 |

| Heater temperature (operating), ºС | 2200 |

| Heater material | tungsten |

| Internal operating vacuum, torr | 1.0*10-5 |

| Vacuum. ТМН pumping speed (nitrogen), l/s | 700 |

| Vacuum. Fore pumping speed, m3/h | 1.0*10-5 |

| Internal gas over pressure (Ar, N2, СО2), not to exceed kg/cm2 | 1.0 |

| Gas flow rate (Ar, N2, СО2), nl/min | 1...100 |

| Cooling. Inlet water pressure, kg/cm2 | 2...3 |

| Cooling. Water flow rate (overall), m3/h | 4...6 |

| Power circuit and control cabinet power supply | 3*(380±38) |

| Power network frequency, Hz | 50/60 |

| Fixed power, kW | 63 |

| Nominal heater power, kW | 45 |

| Heater power voltage, V | 0-14 |

| Control. Constant power accuracy, % | ±0.1 |

| Control cabinet power, kW not to exceed | 7 |

| Height, mm | 5000 |

| Length, mm | 3000 |

| Width, mm | 2000 |

| Mass, not to exceed, kg | 3000 |

| Mass, not to exceed, kg | 500 |

Other products

Machines for growing of silicon monocrystals per Czochralski method

Monocrystal leucosapphire growing facility per Kyropoulous method (Musatov, Goi)

Machines for growingof leucosapphire monocrystal based on horizontally directed crystallization method

Machines for growing of gallium (GaAs) and indium arsenides (InAs) monocrystals

Machines for growing of indium (insb) and gallium atnimonide (gasb) monocrystals per Czochralski method CZ

Hardware for high education and research institutions

GET YOUR CATALOGUETEST

Please fill in your telephone number and our experts will call you back

Ordering products/services

- About us

-

Production

-

Vacuum hardware and customized equipment

- Diaphragm compressor

- Electron beam fusion/refining machine for refractory metals (niobium Nb, tantalum Ta)

- Vacuum shut-offs

- Thermal vacuum test facility (TVACF)

- The ITER Port Plug Test Facility (PPTF)

- Thermal vacuum chamber TVC-110

- Vacuum chamber for testing of high-power pulse hydrogen plasma thrusters

- Experimental thermonuclear installation Tokamak T-15MD

- Carbothermal synthesis facility (csf)

- Large-scale vacuum shaft furnace

- Superhigh vacuum rectangular chamber for fundamental studies

- Cryogenic vacuum facility vu-180

- Vacuum chamber ps-45

- High power plasma thruster test facility

- Gas discharge chamber STIS-1C

- Vacuum chamber with sample transfer system

-

Industrial thermal equipment

-

Vacuum furnaces

-

Electric resistance (batch) furnaces

-

Electric conveyor continuous furnaces

-

Thermaldiffusion and thermocompression equipment

-

Vacuum coating systems

-

-

Crystal growing machines

- Hardware for high education and research institutions

- Machines for growing of sapphire and ruby monocrystals per Bridgman-Stockbarger method

- Machines for growing of silicon monocrystals per Czochralski method

- Monocrystal leucosapphire growing facility per Kyropoulous method (Musatov, Goi)

- Machines for growingof leucosapphire monocrystal based on horizontally directed crystallization method

- Machines for growing of gallium (GaAs) and indium arsenides (InAs) monocrystals

- Machines for growing of indium (insb) and gallium atnimonide (gasb) monocrystals per Czochralski method CZ

-

Magnetic coils

-

Items manufactured from refractory metals and alloys

-

Tungsten

-

Molybdenum

-

Ultra-high-temperature ceramics

-

- Metal Hoses

- Road Construction Equipment

-

-

Services

- News

- Job opportunity

- Documents

- Contacts

Получить консультацию

Подробно расскажем о наших товарах, видах и стоимости доставки,

подготовим индивидуальное предложение для оптовых клиентов!

Задать вопрос

Подробно расскажем о наших товарах, видах и стоимости доставки,

подготовим индивидуальное предложение для оптовых клиентов!

Your name E-mail Phone

Your request

Sent