Products from tungsten-containing alloys

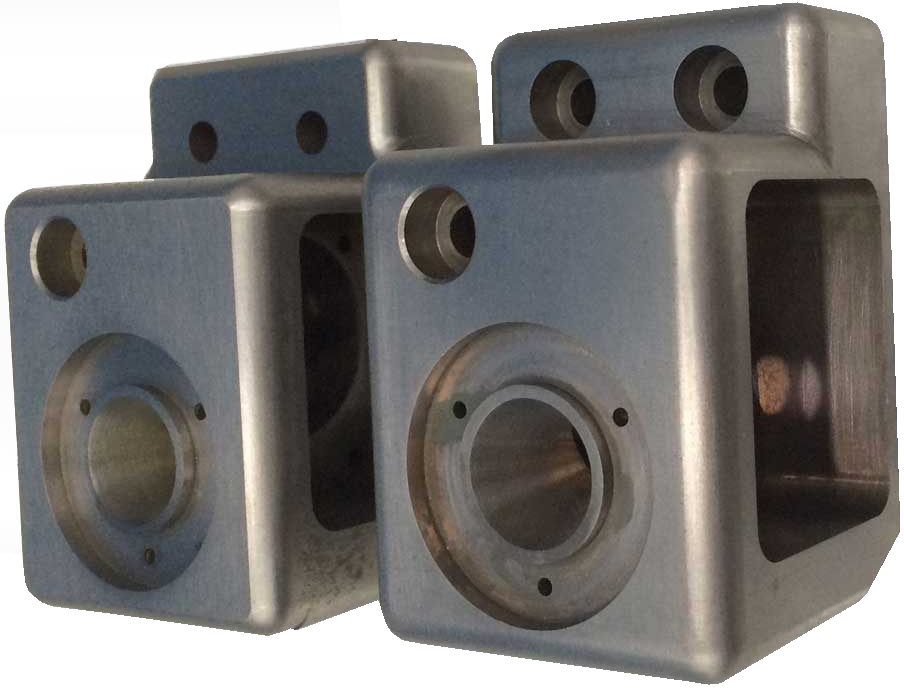

Products from tungsten-containing alloys are widely used in many industries. The main application areas of tungsten alloys are conditioned by their key properties. Tungsten alloys provide high radiation protection due to its high density (tungsten alloys are at least 1,5 times heavier than lead).

This is the reason why tungsten alloys are duly considered as the best material to protect from gamma-radiation in comparison with traditional lead, steel, water and cast iron. Moreover, tungsten has unique combination of qualities and properties enabling to use it at extremely high temperatures. Therefore, products made of tungsten-containing alloys are widely used in many industries.

Alternative ratio or tungsten carbide and cobalt is possible, when so requested by Customer.

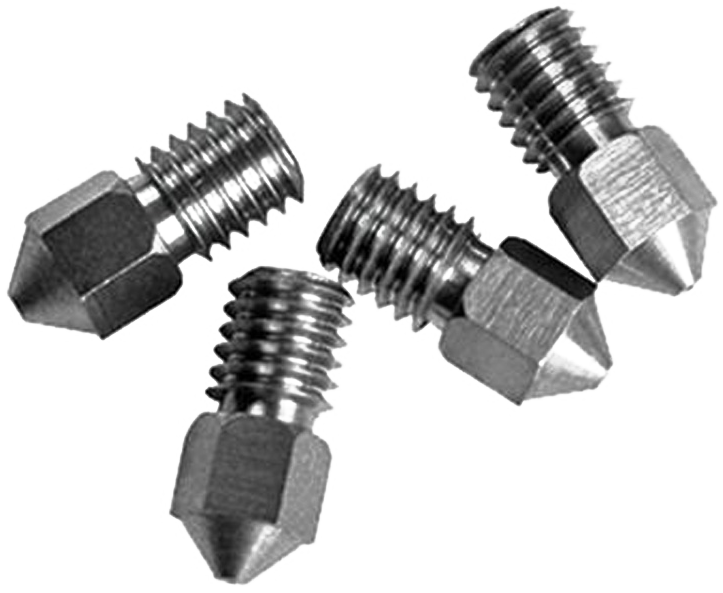

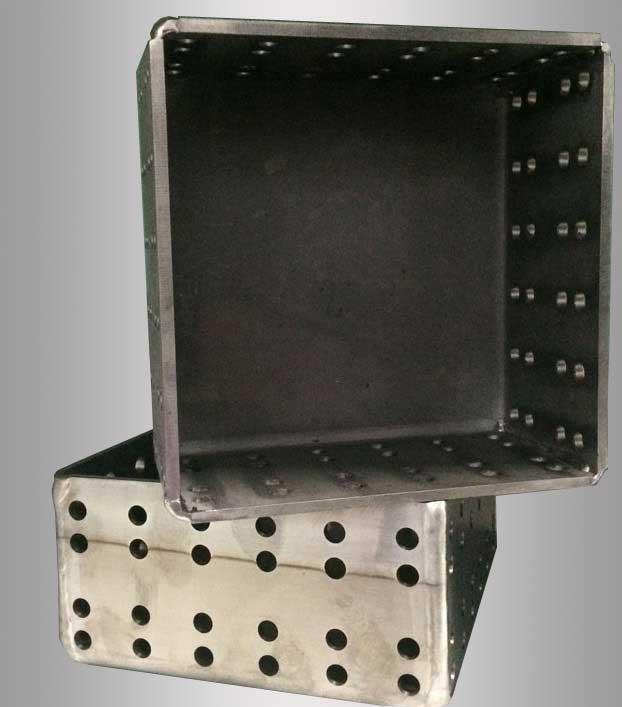

The “NPO “GKMP” LLC ООО supplies pieces from hard tungsten-containing alloys: plates, couplings, shafts etc. per Customer’s drawings, as well as thermocouple rod ВР5/ВР20.

Properties:

- High alloy density

- High radiation resistance

- High durability

- High strength

- Heat strength and heat resistance

- Minimal corrosion sensitivity

- Available cost

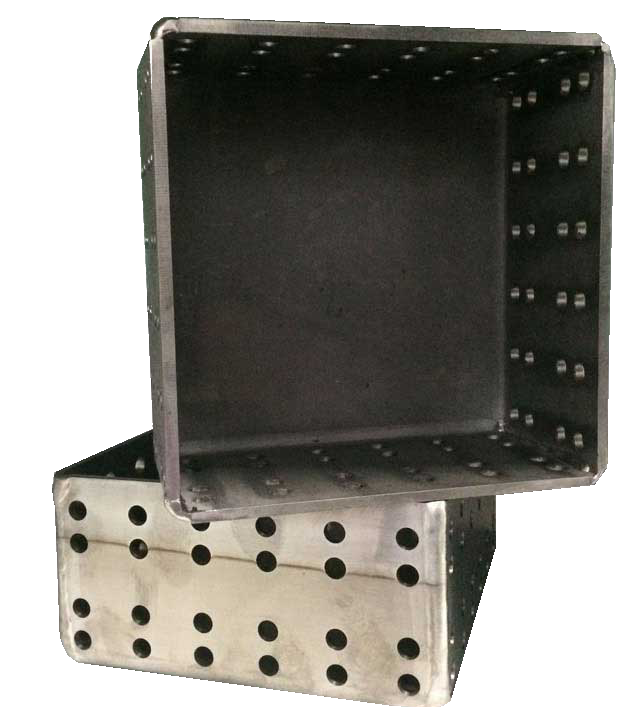

- Parts for radioactivity logging devices;

- Storage vessels for radioactive agents;

- Protective shrouds;

- Collimators;

- Elements of non-destructive control hardware;

- Radiation-measuring and radiation control equipment etc.

Tungsten-copper

| Class | Composition (%), Cu | Composition (%), Impurities ≤ | Composition (%), W | Density, g/cm 3 ≥ | Hardness, НВ kgs/mm2 | Specific resistance, µΩ.cm ≤ | Flexural strength, MPa≥ |

|---|---|---|---|---|---|---|---|

| W50/Cu50 |

50±2.0 |

0.5 |

base |

11.85 |

115 |

3.2 |

- |

| W55/Cu45 |

45±2.0 |

0.5 |

base |

12.30 |

125 |

3.5 |

- |

| W60/Cu40 |

40±2.0 |

0.5 |

base |

12.75 |

140 |

3.7 |

- |

| W65/Cu35 |

35±2.0 |

0.5 |

base |

13.30 |

155 |

3.9 |

- |

| W70/Cu30 |

30±2.0 |

0.5 |

base |

13.80 |

175 |

4.1 |

790 |

| W75/Cu25 |

25±2.0 |

0.5 |

base |

14.50 |

195 |

4.5 |

885 |

| W80/Cu20 |

25±2.0 |

0.5 |

base |

15.15 |

220 |

5.0 |

980 |

| W85/Cu15 |

15±2.0 |

0.5 |

base |

15.90 |

240 |

5.0 |

1080 |

| W90/Cu10 |

10±2.0 |

0.5 |

base |

16.75 |

260 |

6.5 |

1160 |

Tungsten-nickel-iron

| Composition (%), Ni | Composition(%), Fe | Density, g/cm3≥ | |

|---|---|---|---|

| W90 |

7 |

3 |

16.85-17.25 |

| W92.5 |

5.25 |

2.25 |

17.15-17.85 |

Tungsten carbide

| Marking | Density, g/cm3 | Hardness, HRA | Flexural strength, MPa |

|---|---|---|---|

| YG6X |

14.8-15.1 |

≥91 |

≥1420 |

| YG6 |

14.7-15.1 |

≥89.5 |

≥1520 |

| YG8 |

14.6-14.9 |

≥89 |

≥1470 |

| YG8.2 |

14.4-15.0 |

≥88 |

≥1450 |

| YG8L |

14.6-15.0 |

≥89 |

≥1450 |

| YG15 |

13.9-14.2 |

≥86.5 |

≥2060 |

| HK12 |

14.2-14.7 |

≥87.5 |

≥2100 |

| KY10 |

14.1-14.5 |

≥87.5 |

≥2060 |

| YG20 |

13.4-13.8 |

≥83.5 |

≥2480 |

| YG20C |

13.4-13.8 |

≥82 |

≥2480 |

| YG20D |

13.4-13.8 |

≥82 |

≥2300 |

| YSN30 |

13.9-14.9 |

≥87 |

≥1900 |

Alternative ratio or tungsten carbide and cobalt is possible, when so requested by Customer.

GET YOUR CATALOGUETEST

Why choose us?

- About us

-

Production

-

Vacuum hardware and customized equipment

- Diaphragm compressor

- Electron beam fusion/refining machine for refractory metals (niobium Nb, tantalum Ta)

- Vacuum shut-offs

- Thermal vacuum test facility (TVACF)

- The ITER Port Plug Test Facility (PPTF)

- Thermal vacuum chamber TVC-110

- Vacuum chamber for testing of high-power pulse hydrogen plasma thrusters

- Experimental thermonuclear installation Tokamak T-15MD

- Carbothermal synthesis facility (csf)

- Large-scale vacuum shaft furnace

- Superhigh vacuum rectangular chamber for fundamental studies

- Cryogenic vacuum facility vu-180

- Vacuum chamber ps-45

- High power plasma thruster test facility

- Gas discharge chamber STIS-1C

- Vacuum chamber with sample transfer system

-

Industrial thermal equipment

-

Vacuum furnaces

-

Electric resistance (batch) furnaces

-

Electric conveyor continuous furnaces

-

Thermaldiffusion and thermocompression equipment

-

Vacuum coating systems

-

-

Crystal growing machines

- Hardware for high education and research institutions

- Machines for growing of sapphire and ruby monocrystals per Bridgman-Stockbarger method

- Machines for growing of silicon monocrystals per Czochralski method

- Monocrystal leucosapphire growing facility per Kyropoulous method (Musatov, Goi)

- Machines for growingof leucosapphire monocrystal based on horizontally directed crystallization method

- Machines for growing of gallium (GaAs) and indium arsenides (InAs) monocrystals

- Machines for growing of indium (insb) and gallium atnimonide (gasb) monocrystals per Czochralski method CZ

-

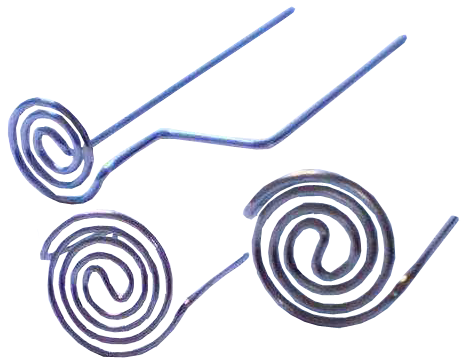

Magnetic coils

-

Items manufactured from refractory metals and alloys

-

Tungsten

-

Molybdenum

-

Ultra-high-temperature ceramics

-

- Metal Hoses

- Road Construction Equipment

-

-

Services

- News

- Job opportunity

- Documents

- Contacts