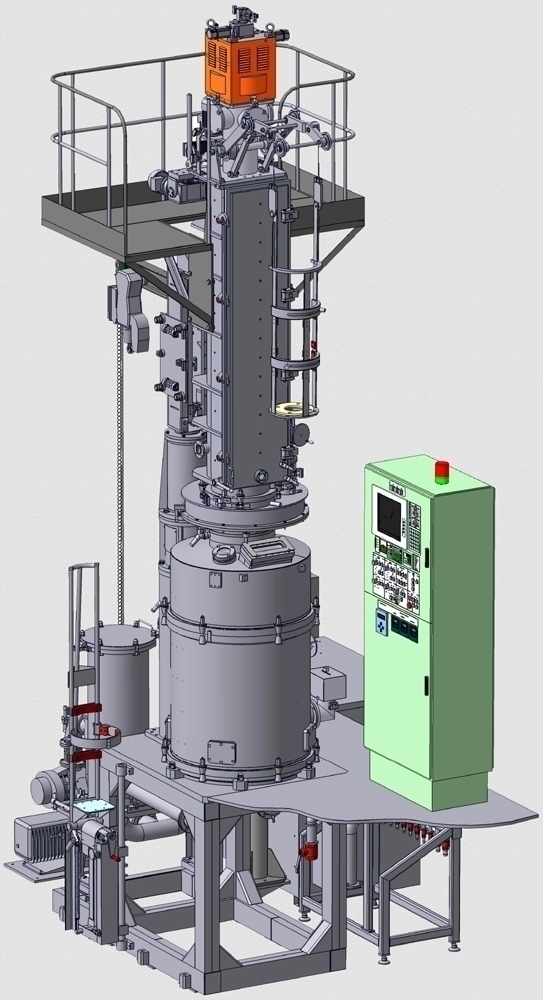

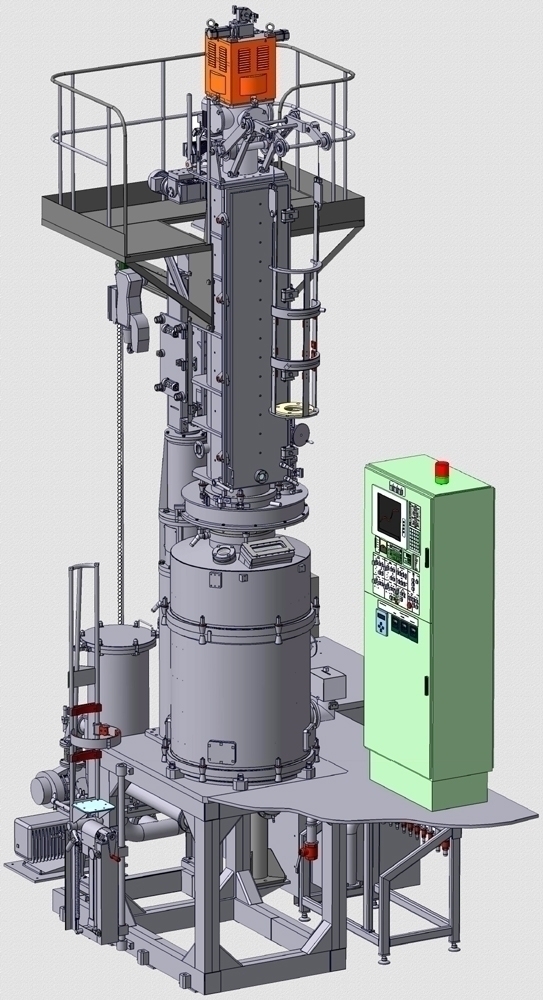

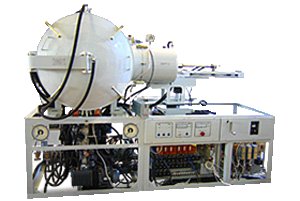

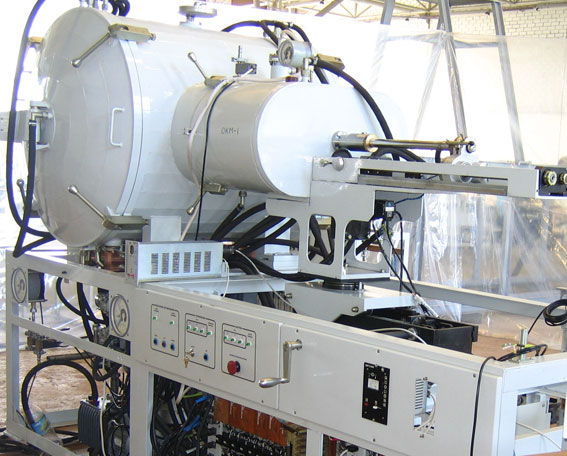

Machines for growing of silicon monocrystals per Czochralski method

In order to grow a semiconductor silicon monocrystal with specific performances a magnet can be used to suppress convection of the melt.

To improve the growing speed of the crystal we propose a water-cooled pit equipped with electromagnetic drive for lifting and plunging. Water-cooled pit increases the crystal growing speed by 1.5-2 times and improves some key characteristics.

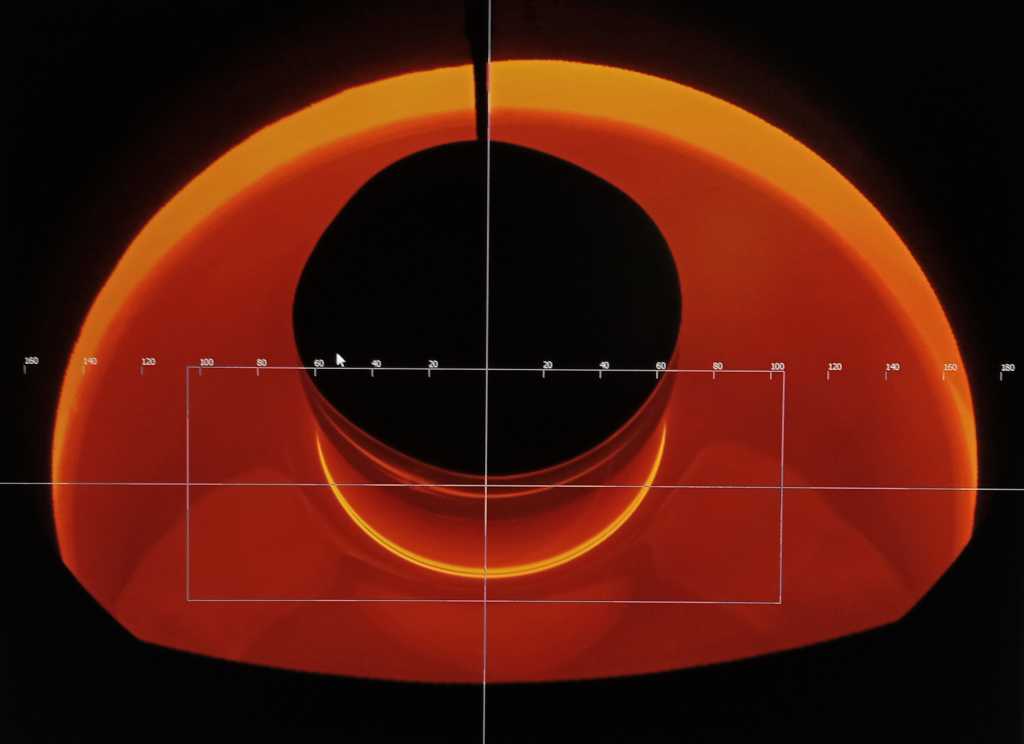

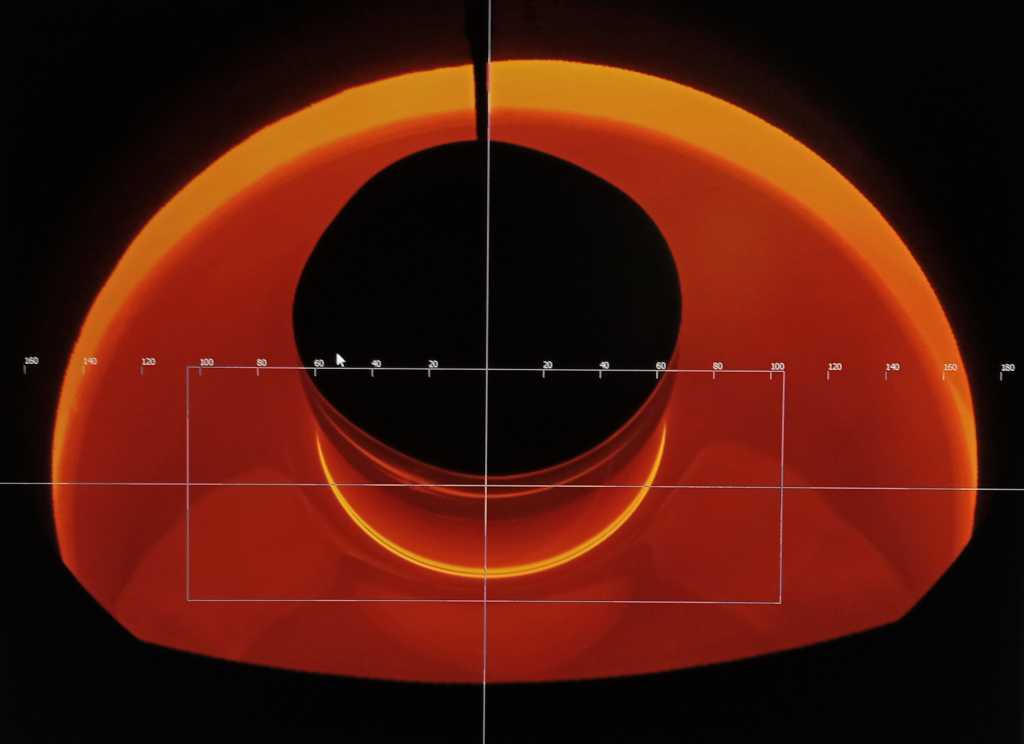

Diameter of the crystal is defined byTV camera. Pyrometers can be mounted to perform temperature control of the heater and/or melt when necessary.

The main pump is represented by a single-module vacuum facility, that includes a Roots pump and a sliding vane rotary pump, including the control unit. To maintain required pressure level inside the operating chamber at constant gas flow, the vacuum facility controls the pumping speed by adjusting rotation frequency. A specific dust filter is mounted in front of the machine for self-cleaning to keep continuous processes (up to 400 hours) uninterrupted without significant losses in pumping speed.

All stages of crystal growing – from leakage check to cooling down of the crystal– are completely automatized.

Currently the Russian semiconductor industry normally uses silicon monocrystals 3,4,6 and 8 inches in diameter. In future 12-inch crystals are expected to be used. The “NPO “GKMP” LLC can manufacture facilities for silicon crystal growing of any diameter.

The machines are customized under approved Technical assignment. Any performances can be changed at your convenience.

Benefits of silicon crystal growing machines per Czochralski method produced by the “NPO “GKMP” LLC

- Possible use of magnet that suppresses convection of the melt to grow semiconductor monocrystals.

- Mounted water-cooled pit with electromechanical drive for lifting and plunging. Efficient adsorption of heat is carried out via specific coating of the pit.

- Fully automatized process including the seed placement .

- A specific dust filter is mounted in front of the machine for self-cleansing that ensures continuous processes (up to 400 hours) without significant losses in pumping speed.

- Configuration fit for “sun” and semiconductor silicon.

| Property | Meaning |

|---|---|

| Crystal diameter, mm, not to exceed | 300 |

| Crystal length, mm, not to exceed | 3200 |

| Crucible diameter, inch, not to exceed | 32 |

| Crucible capacity, kg, not to exceed | 450 |

| Seed travel speed, mm/min, growing | 0.1-30 |

| Seed travel speed, mm/min, positioning | 600 |

| Seed rotation frequency, rpm, not to exceed | 25 |

| Travel and seed rotation frequency tolerance, % | ± 0.1 |

| Crucible operating stroke, mm | 450 |

| Crucible travel speed, rpm | 0.01-50 |

| Crucible rotation speed, rpm, not to exceed | 25 |

| Ultimate residual pressure, mmHg (vacuum) | 7.5 •10-4 |

| Cooling water flow rate, m3/h, not to exceed | 16 |

| Inlet cooling water pressure, MPa, not to exceed | 0.2 |

| Argon flow rate, l/min, not to exceed | 60 |

| Automated control system | Yes |

| Adaptive crystal diameter control system | Yes |

|

Automatic seed placement |

Yes |

|

Power supply: voltage, V frequency, Hz |

3-phase 380/220 50 |

| Maximal power of the main heater, kWA, not to exceed |

180 |

| Maximal power of the bottom heater, kWA, not to exceed |

90 |

| Diameter * Growth chamber height, mm |

1200 * 1490 |

| Diameter * Crystal chamber height, mm |

400 * 3600 |

| Mass, kg |

Growing module 7500 |

| Dimensions, mm |

4400*3950*9500 (10700 while unloading) |

Other products

GET YOUR CATALOGUETEST

Why choose us?

- About us

-

Production

-

Vacuum hardware and customized equipment

- Diaphragm compressor

- Electron beam fusion/refining machine for refractory metals (niobium Nb, tantalum Ta)

- Vacuum shut-offs

- Thermal vacuum test facility (TVACF)

- The ITER Port Plug Test Facility (PPTF)

- Thermal vacuum chamber TVC-110

- Vacuum chamber for testing of high-power pulse hydrogen plasma thrusters

- Experimental thermonuclear installation Tokamak T-15MD

- Carbothermal synthesis facility (csf)

- Large-scale vacuum shaft furnace

- Superhigh vacuum rectangular chamber for fundamental studies

- Cryogenic vacuum facility vu-180

- Vacuum chamber ps-45

- High power plasma thruster test facility

- Gas discharge chamber STIS-1C

- Vacuum chamber with sample transfer system

-

Industrial thermal equipment

-

Vacuum furnaces

-

Electric resistance (batch) furnaces

-

Electric conveyor continuous furnaces

-

Thermaldiffusion and thermocompression equipment

-

Vacuum coating systems

-

-

Crystal growing machines

- Hardware for high education and research institutions

- Machines for growing of sapphire and ruby monocrystals per Bridgman-Stockbarger method

- Machines for growing of silicon monocrystals per Czochralski method

- Monocrystal leucosapphire growing facility per Kyropoulous method (Musatov, Goi)

- Machines for growingof leucosapphire monocrystal based on horizontally directed crystallization method

- Machines for growing of gallium (GaAs) and indium arsenides (InAs) monocrystals

- Machines for growing of indium (insb) and gallium atnimonide (gasb) monocrystals per Czochralski method CZ

-

Magnetic coils

-

Items manufactured from refractory metals and alloys

-

Tungsten

-

Molybdenum

-

Ultra-high-temperature ceramics

-

- Metal Hoses

- Road Construction Equipment

-

-

Services

- News

- Job opportunity

- Documents

- Contacts