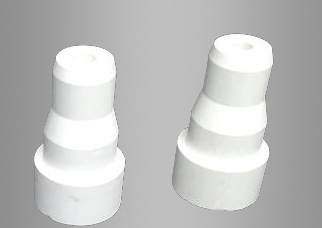

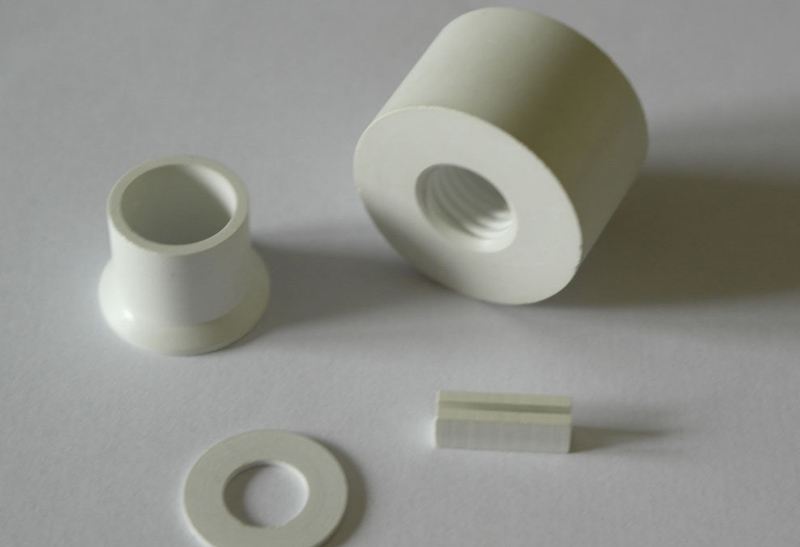

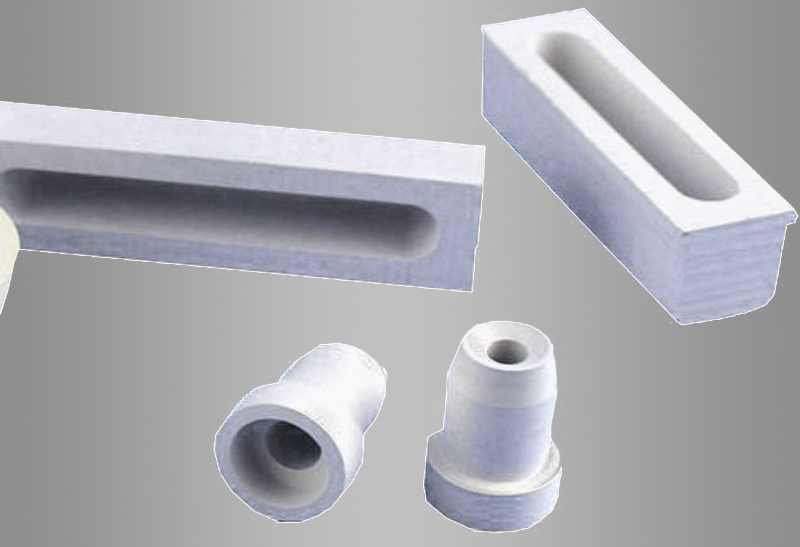

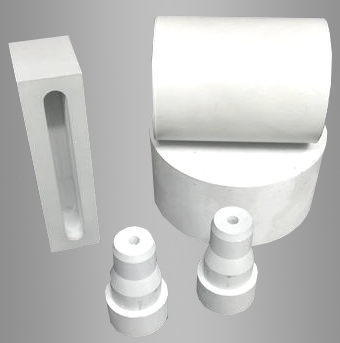

Ceramic products based on boron nitride (BN)

One of the key characteristics of boron nitride is that it provides to any item more thermal resistance, density and stability. Boron nitride is widely used in heavy industry and for chemicals.

Boron nitride ceramics was widely adopted in aircraft and rocket engineering, machinery and glass melting, chemical industry, energy and metallurgy. Production of high temperature hardware often involves crucibles, insulators and electric vacuum tools of boron nitride.

A unique combination of thermal, physical and chemical characteristics of boron nitride ceramics make it perfect to meet complex needs and tackle the entire range of production challenges.

Characteristics:

- Thermal capacity

- Non-toxic

- Chemical inertness

- High dielectric strength

- Low dielectric capacity

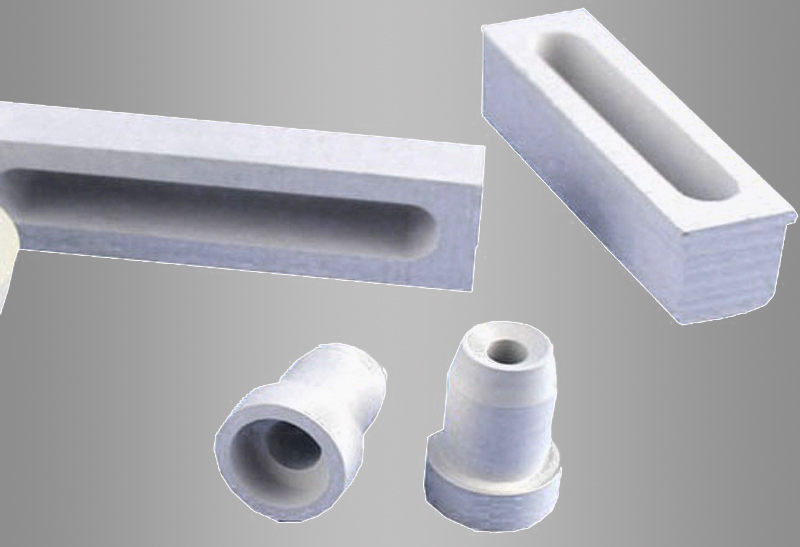

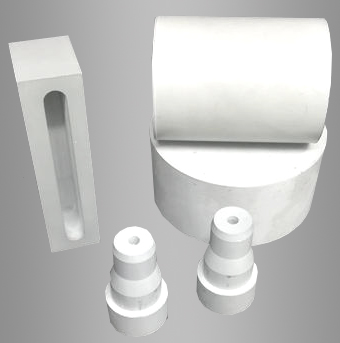

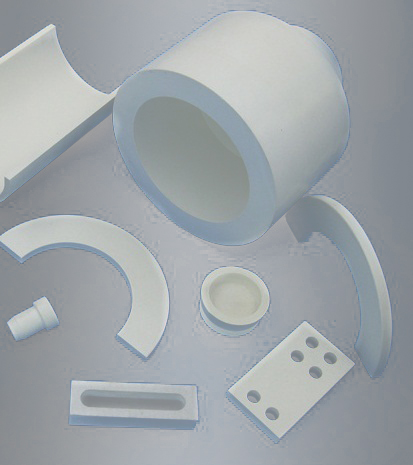

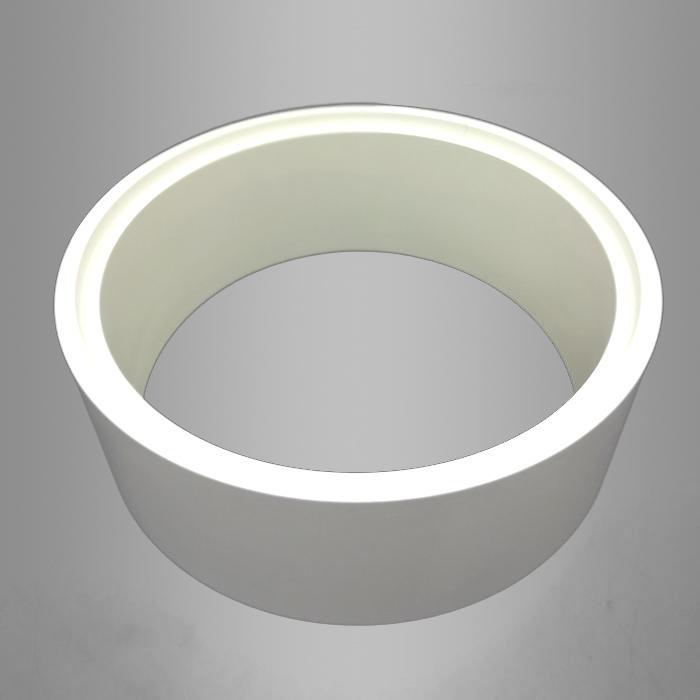

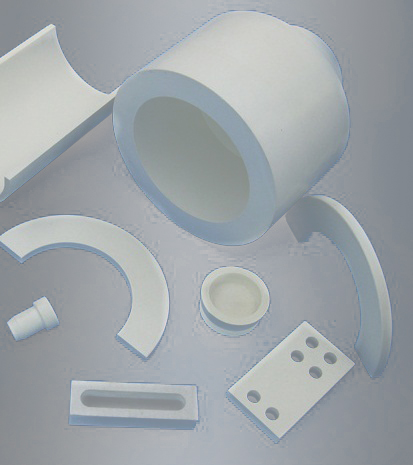

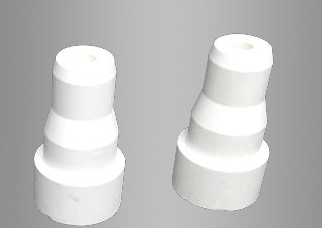

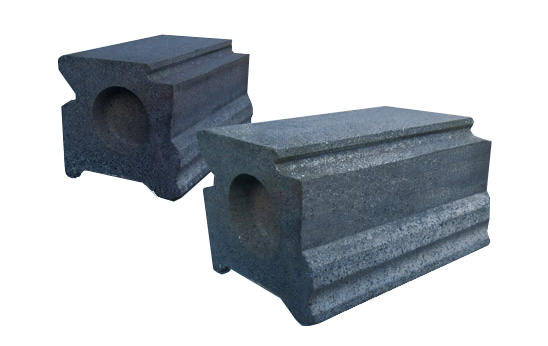

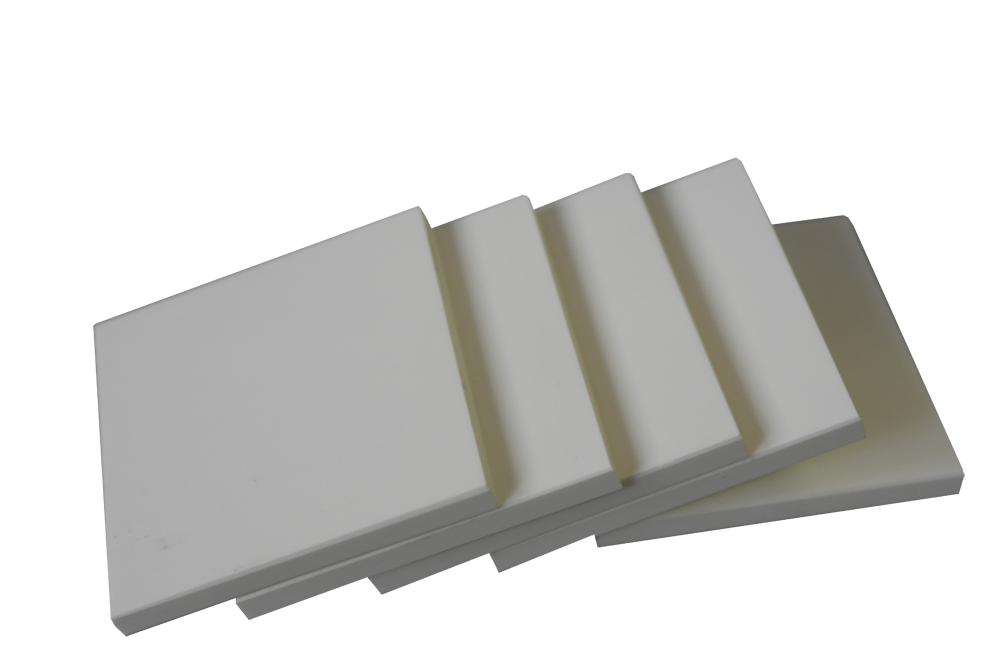

We supply heat resistive ceramics based on hexagonal boron nitride (of different shapes and dimensions per Customer’s needs and requirements).

Application:

- Crucibles, insulators and high temperature ceramics;

- High temperature lubricants;

- Synthesis of extra-soil substances;

- Production of electric vacuum hardware and semiconductors.

Hot-pressed hexagonal boron nitride (BN)

| Composition | BN˃99% | BN˃98% | BN+SiC+ZrO2 | BN+AlN |

|---|---|---|---|---|

| Binder |

Self-binding |

B2O3 |

AlBO3 |

AlBO3 |

| Density, g/cm3 |

1.9-2.0 |

2.1-2.2 |

2.3-3.0 |

2.5-2.6 |

| Specific resistance (at 25°C), Ω/cm |

>1014 |

˃1013 |

˃1012 |

˃1014 |

|

Maximal operating temperature, Oxidizer, °С |

900 |

900 |

900 |

900 |

|

Maximal operating temperature, Inert gas , °С |

2300 |

2000 |

1700 |

1700 |

|

Maximal operating temperature, High vacuum, °С |

1800 |

1800 |

1700 |

1700 |

| Flexural strength, MPa |

25 |

75 |

100 |

130 |

| Compressive strength, MPa |

100 |

100 |

300 |

250 |

| Thermal expansion coefficient 25-1000°C, 10-6/K |

0-2 |

2.0 |

4.0 |

4.5 |

| Thermal conductivity, W/mK |

50 |

30 |

40 |

60 |

We produce thermal resistive ceramics based on hexagonal boron nitride of different shapes and dimensions per Customer’s needs and requirements.

GET YOUR CATALOGUETEST

Why choose us?

- About us

-

Production

-

Vacuum hardware and customized equipment

- Diaphragm compressor

- Electron beam fusion/refining machine for refractory metals (niobium Nb, tantalum Ta)

- Vacuum shut-offs

- Thermal vacuum test facility (TVACF)

- The ITER Port Plug Test Facility (PPTF)

- Thermal vacuum chamber TVC-110

- Vacuum chamber for testing of high-power pulse hydrogen plasma thrusters

- Experimental thermonuclear installation Tokamak T-15MD

- Carbothermal synthesis facility (csf)

- Large-scale vacuum shaft furnace

- Superhigh vacuum rectangular chamber for fundamental studies

- Cryogenic vacuum facility vu-180

- Vacuum chamber ps-45

- High power plasma thruster test facility

- Gas discharge chamber STIS-1C

- Vacuum chamber with sample transfer system

-

Industrial thermal equipment

-

Vacuum furnaces

-

Electric resistance (batch) furnaces

-

Electric conveyor continuous furnaces

-

Thermaldiffusion and thermocompression equipment

-

Vacuum coating systems

-

-

Crystal growing machines

- Hardware for high education and research institutions

- Machines for growing of sapphire and ruby monocrystals per Bridgman-Stockbarger method

- Machines for growing of silicon monocrystals per Czochralski method

- Monocrystal leucosapphire growing facility per Kyropoulous method (Musatov, Goi)

- Machines for growingof leucosapphire monocrystal based on horizontally directed crystallization method

- Machines for growing of gallium (GaAs) and indium arsenides (InAs) monocrystals

- Machines for growing of indium (insb) and gallium atnimonide (gasb) monocrystals per Czochralski method CZ

-

Magnetic coils

-

Items manufactured from refractory metals and alloys

-

Tungsten

-

Molybdenum

-

Ultra-high-temperature ceramics

-

- Metal Hoses

- Road Construction Equipment

-

-

Services

- News

- Job opportunity

- Documents

- Contacts