Ultra-high-temperature ceramics

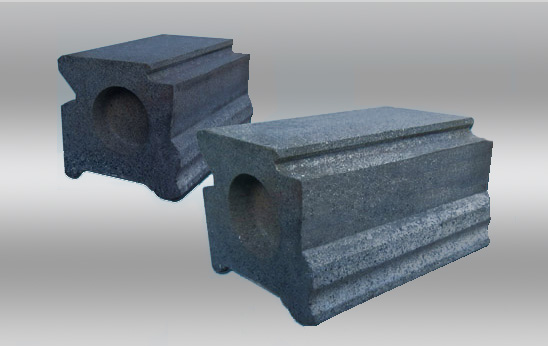

High temperature ceramics draws attention of manufacturers due to specific properties and a broad range of application in different industries that require high temperatures.

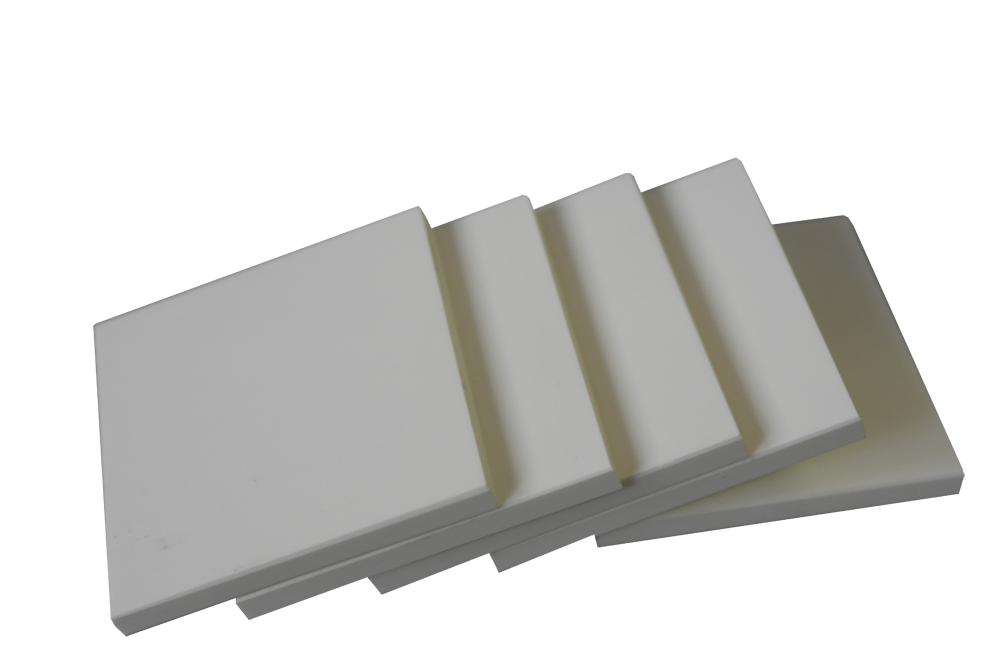

Benefits of high-temperature ceramic products

No harmful substances are emitted while heating making them safe for health and environment.

Ensures stable dimensions and shape of products at different temperatures, which is crucial for different industries.

Not electrically conductive, that renders them very useful for electronics.

Resistive to aggressive media and corrosion, that renders them perfect for use in chemical industry.

Can with stand extremely high temperatures without any deformation or degradation whatever.

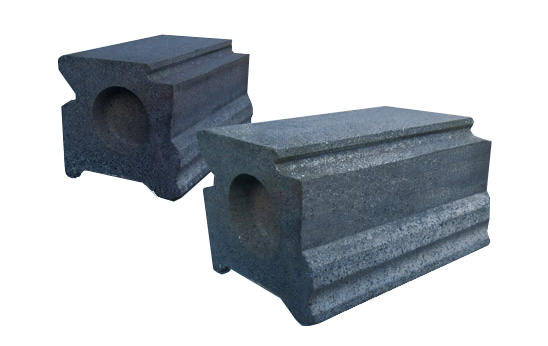

Physical properties, hardness factor and stability at high temperatures put high temperature ceramics high for high temperature treatment of materials both in vacuum or without one.

Nevertheless, resistance to oxidation limited by 500ºC is considered one of the crucial disadvantages of this type. Contact with air can substantially affect its high temperature properties. This is the reason why high temperature ceramics is used in nodes isolated from air.

Silicon carbide, due to its unique combination of physical anthropologists including power electronics, machinery, metallurgy, chemical and food production oil and gas production expenses.

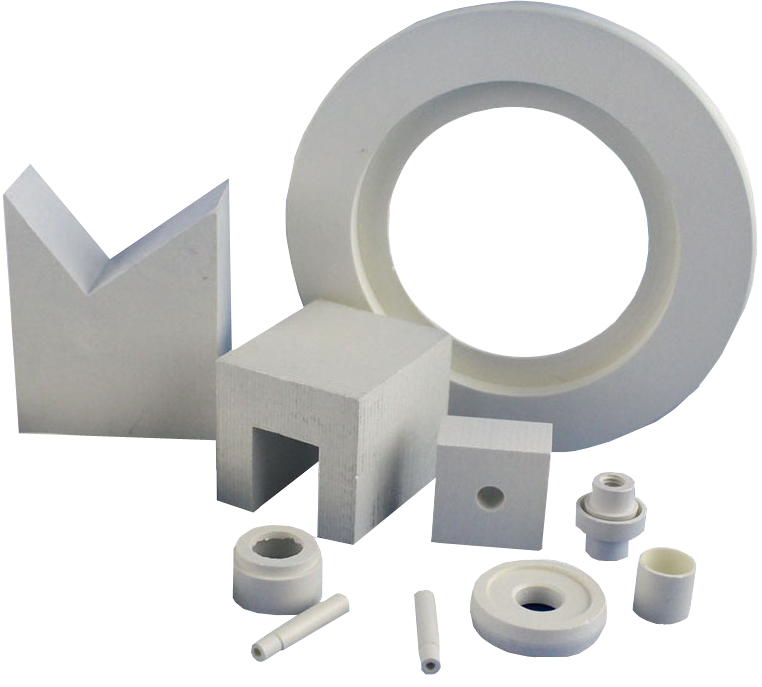

Zirconium dioxide is used to produce extra heat resistive units, heat resistive enamel, refractory glass, different types of ceramics, ceramic pigments, hard electrolytes, thermal protection coatings, catalyzers, artificial gems, cutting tools and abrasive materials.

In recent years zirconium dioxide is widely used in fiber optics and production of ceramics designed for electronics.

Boron nitride was widely adopted in heavy industry and chemical industry, as well as in several branches of electronics.

Application of aluminum oxide ceramics is rather wide thanks to its substantial hardness, heat resistance and good insulation properties of material. High temperature ceramics of different modifications of Al203 is in high demand in different industries of oil production and chemicals, as well as in others.

Advanced ZTA-based ceramics based (combination of Al2O3 and ZrO2) is mostly used to produce insulators, sensors, piston-bushings and pump components, water supply system components, housings and LED chips.

Application of high temperature ceramics in a technical process are still an object of study and new initiatives concerning its possible use.

Why choose us? Items manufactured from refractory metals and alloys

GET YOUR CATALOGUETEST