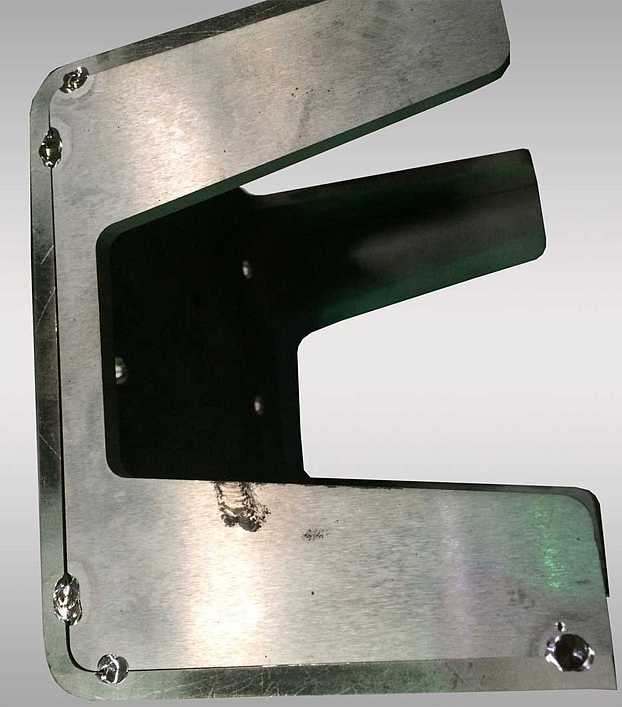

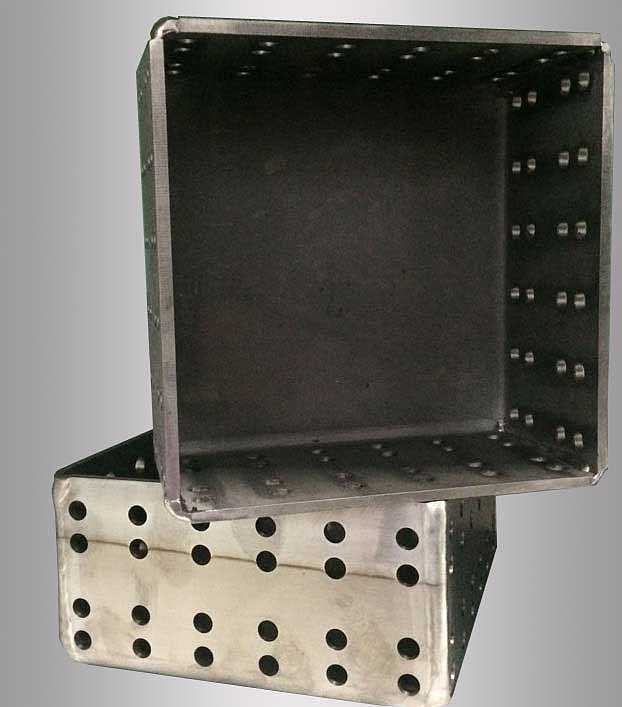

Tungsten boat. Welding of tungsten pieces

Tungsten boat. Welding of tungsten pieces

Tungsten is welded once pre-heated up to 500°С, as at the ambient temperature it becomes fragile. Plasticity of welded seams is higher after additional thermal treatment.

Key benefits of tungsten boats:

- Heat resistance;

- Thermal creep resistance;

- High elasticity modulus;

- Lowthermalexpansioncoefficient;

- Durability and strength;

- Corrosion resistance;

- Chemical inertness, resistance to aggressive agents;

The more industries develop, the more ground is gained by refractory metals and their alloys. Nevertheless, the machining of such materials is not easy due to its strength properties and refractory nature, and requires a lot of effort. Refractory alloys obtained by pressing are quite hard to be machined. Tungsten can be welded only once being pre-heated up to 500ºC, as it is getting fragile at ambient temperature. The plasticity of welded seams is increased after additional thermal treatment.

Our company developed a state-of-the-art tungsten welding technology.

| Material |

Tungsten |

| Density, g/cm3 |

19.3 |

| Thermal conductivity, 25°СW/m•K |

167 |

| Thermal expansion coefficient, 25°С (10-6/К) |

4.67 |

We supply tungsten boats (tungsten vaporizers) of different dimensions and shapes per Customer’s specification.

Documents

Получить консультацию

Подробно расскажем о наших товарах, видах и стоимости доставки,

подготовим индивидуальное предложение для оптовых клиентов!

Задать вопрос

Подробно расскажем о наших товарах, видах и стоимости доставки,

подготовим индивидуальное предложение для оптовых клиентов!

Your name E-mail Phone

Your request

Sent