Tungsten

- The highest melting point among other refractory metals - 3420 °С;

- High density – 19.3 g/cm3;- hardness (HV30 >460);

- Chemical stability: up to 400°Сin oxygen, up to 600°Сin hydrogen, up to 700°Сin ammonium and about 800°Сin carbon oxide;

- Creep resistance and long-term strength (much higher than that of molybdenum, tantalum, niobium at a sample temperature of about 1100 °С);

- Thermal conductivity and red hardness: once the full red heat is reached, the tungsten does not lose any robustness after cooling down;

-

Maximal operating temperature: in oxygen-free shielding and reducing the ambient temperature to 2600°С.

- As jig for high temperature hydrogen and vacuum furnaces;

- For cathode production: as the base for infusible welding electrodes;

- For glass production (fusible electrodes and tungsten stirrer);

- For pressing of hot metals;

- For production of heat resistive parts of space rockets;

- As shrouds to decrease radiation emission flow in nuclear energy etc.

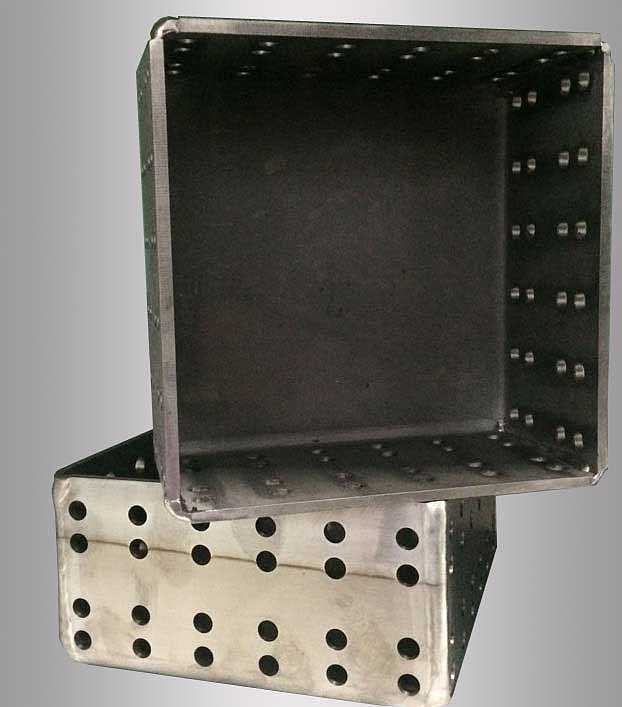

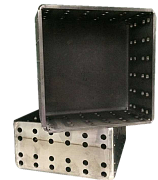

Tungsten crucibles

Technical characteristics:

- High tungsten purity – above 99.95%;

- High density – 18.2 g/cm3;

- Surface roughness - Rz 6.3 max

Tungsten crucible is reliable and durable, has a high strength and elasticity, fit to withstand high temperatures in vacuum and inert gases (up to 2600°С).

Standard dimensions of crucibles:

|

Diameter (mm)

|

Wall thickness (mm)

|

Height (mm)

|

|

30-50 |

8-10 |

<1300 |

|

50-100 |

8-15 |

<1300 |

|

100-150 |

10-15 |

<1300 |

|

150-200 |

12-20 |

<1300 |

|

200-300 |

15-20 |

<1300 |

|

300-400 |

15-30 |

<1300 |

|

400-450 |

15-30 |

<1300 |

|

450-550 |

15-30 |

<1300 |

|

550-650 |

25-35 |

<1300 |

|

650-750 |

25-35 |

<1300 |

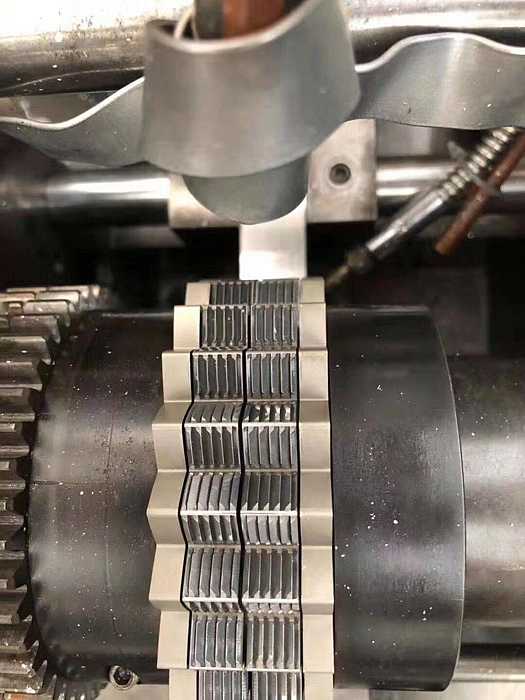

Tungsten crucibles for melting are produced by different methods depending on their application purpose:

- Powder sintering (used for crucibles of any shape and dimensions);

- Turning (complex machining of workpieces);

- Plasma sputtering

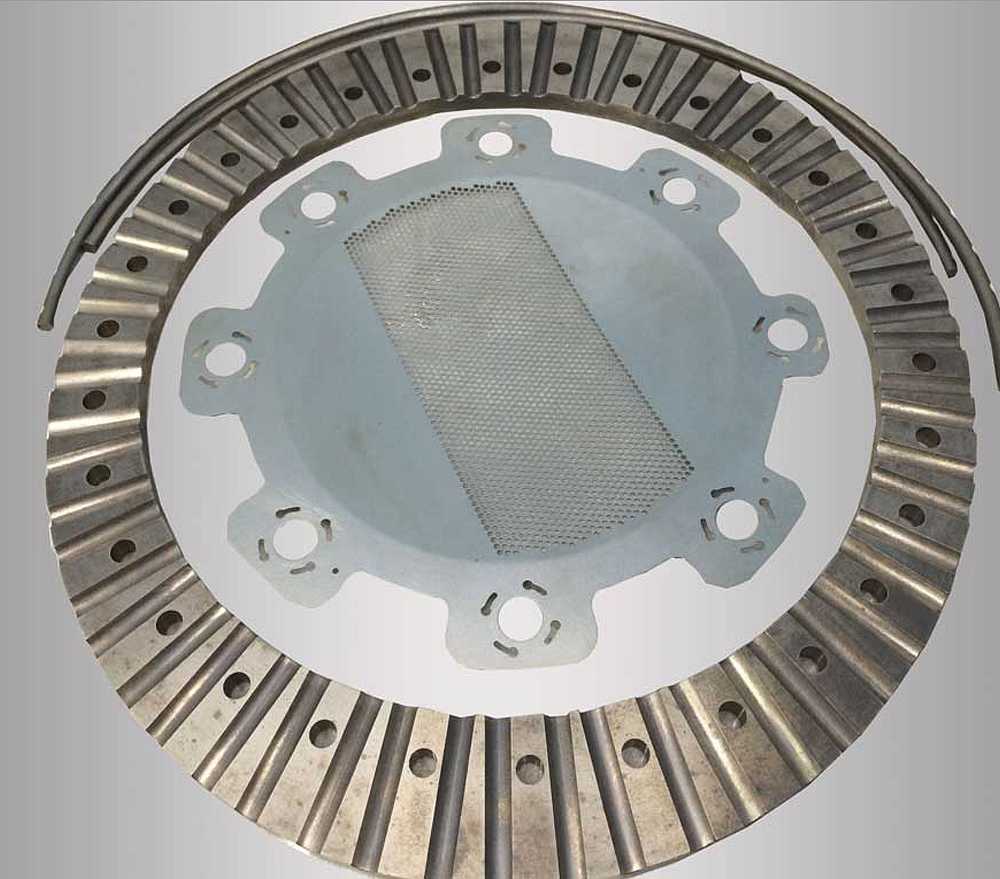

Tungsten screens

| Material |

Tungsten |

| Density, g/cm3 |

19.3 |

| Thermal conductivity, 25°СW/m•К |

167 |

| Thermal expansion coefficient, 25°С (10-6/К) |

4.67 |

Protection shroud can be of any shape and configuration depending on its application purpose.

Our company delivers shrouds manufactured under Customers drawings taking into account any requirements.

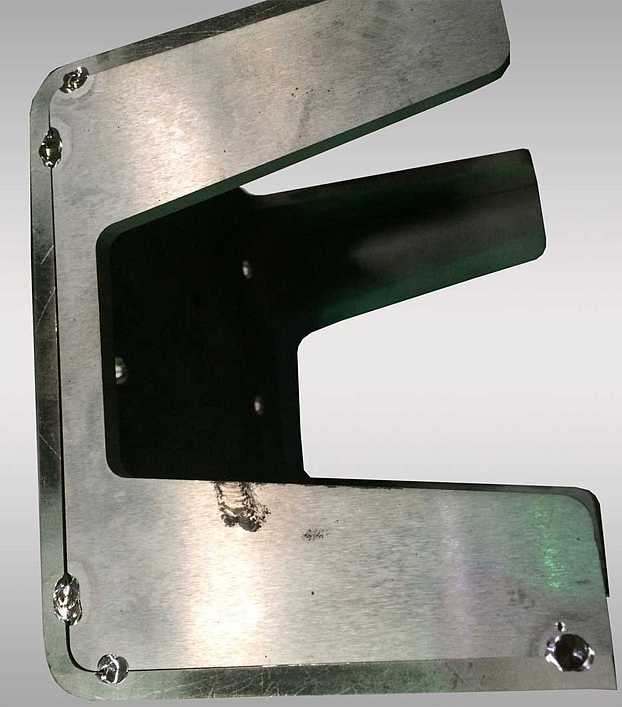

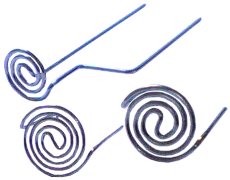

Tungsten electric heaters

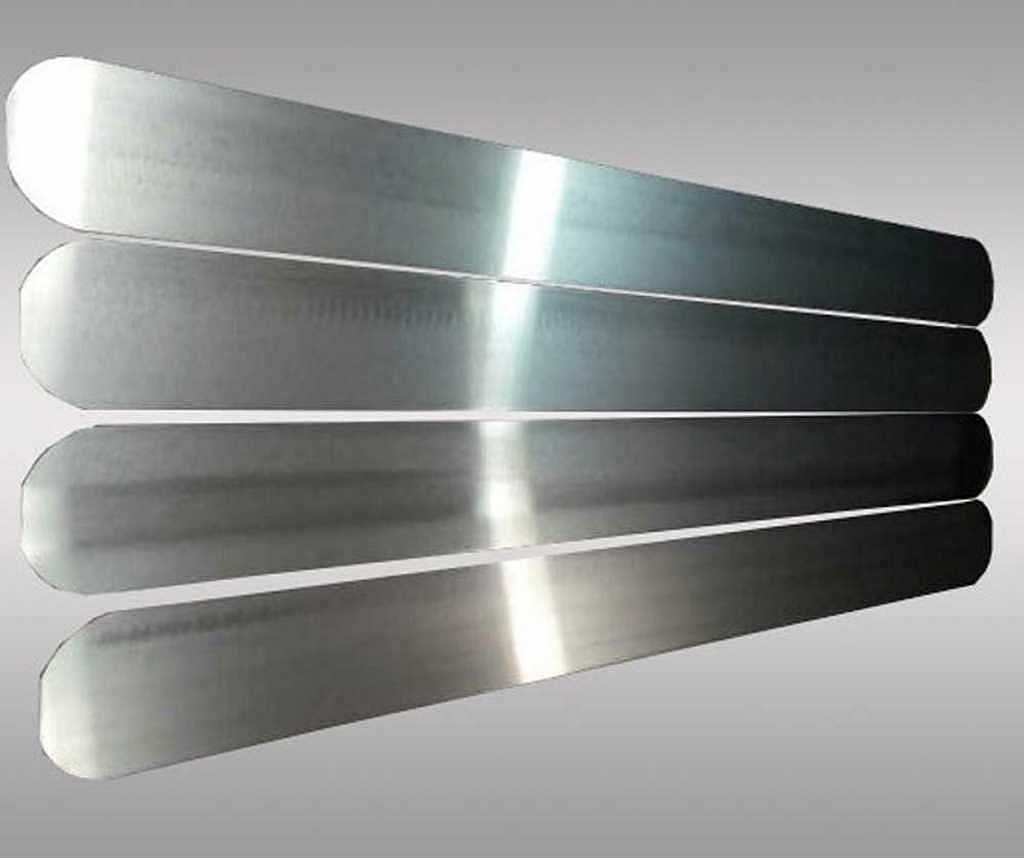

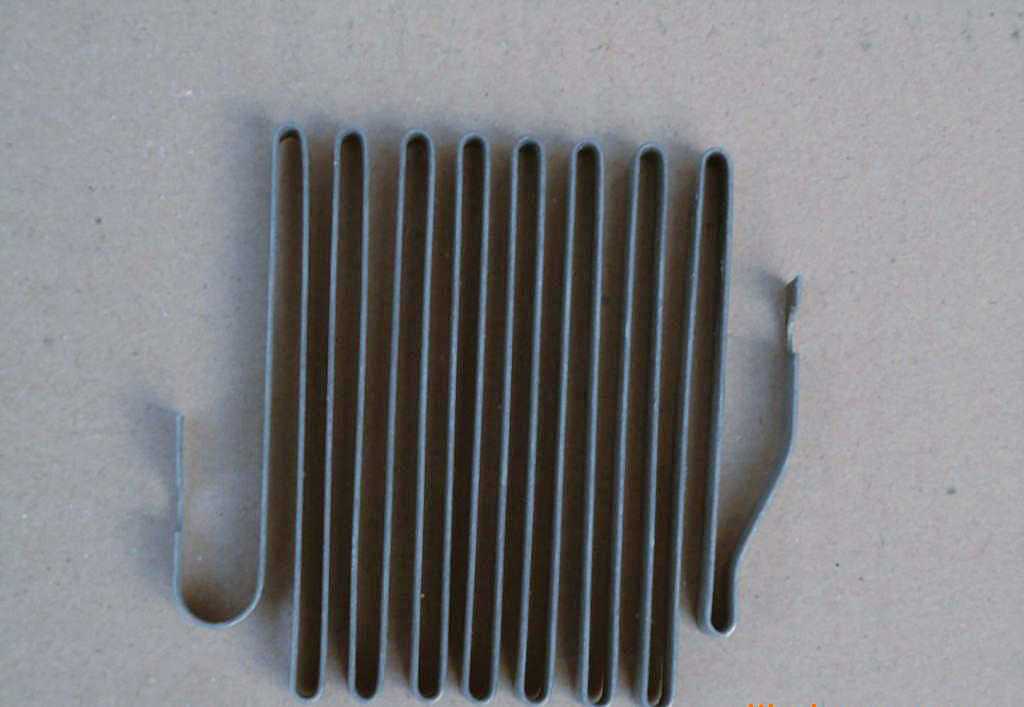

Among definite benefits of tungsten one can name high operating temperature (in comparison with composite materials), ability to maintain high temperatures while prolonged outgassing period (in time). The maximal operating temperature of the tungsten heater directly depends on thickness of its body plates and on chemical composition of the operating medium inside the furnace.

Band

Spiral

Circular

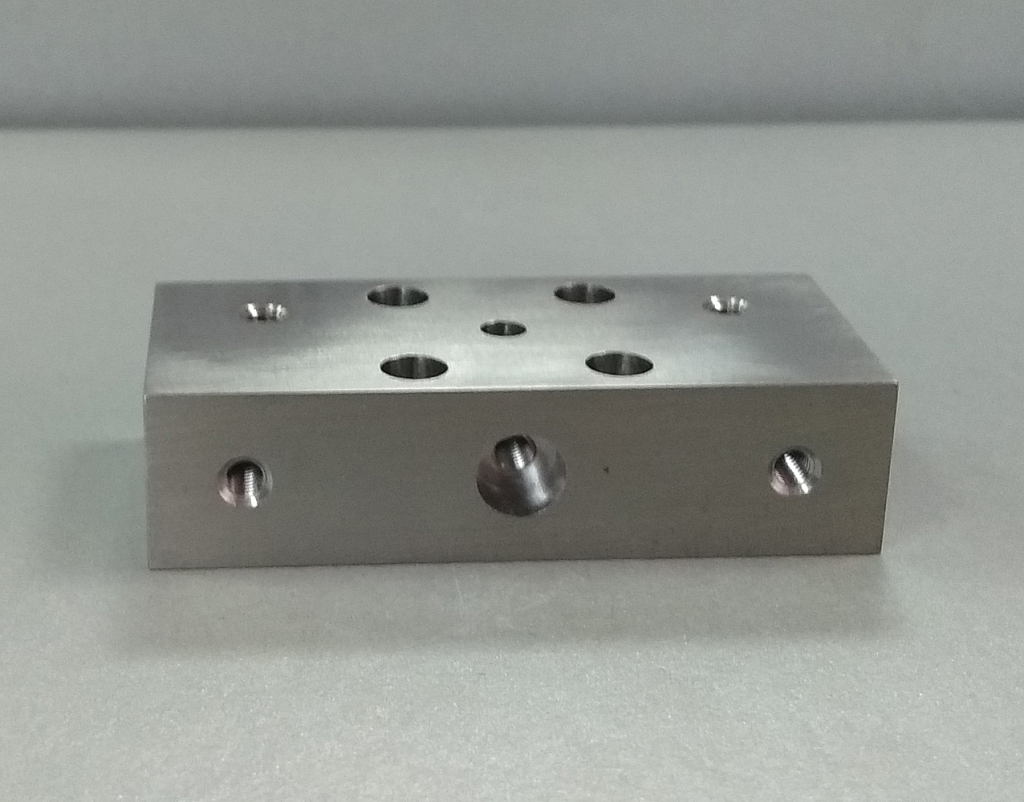

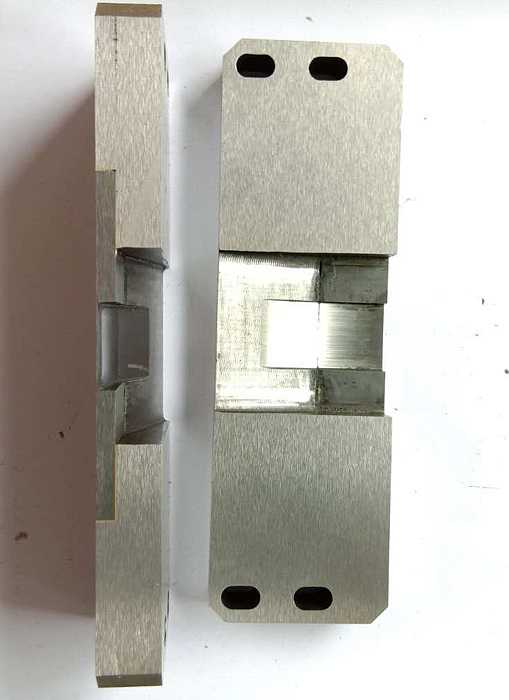

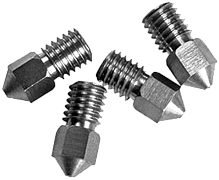

Metalwork, tungsten bolts and washers

- High heat resistance;

- High heat strength;

- Durability;

- Corrosion resistance;

-

Highthermalstabilityvalues.

| Material |

Tungsten |

| Density, g/cm3 |

19.3 |

| Thermal conductivity, 25°СW/m•K |

167 |

| Thermal expansion coefficient, 25°С (10-6/К) |

4.67 |

We supply washers, bolts, metalwork, nuts and other tungsten micropieces of any dimension and configuration per customer’s Specification.

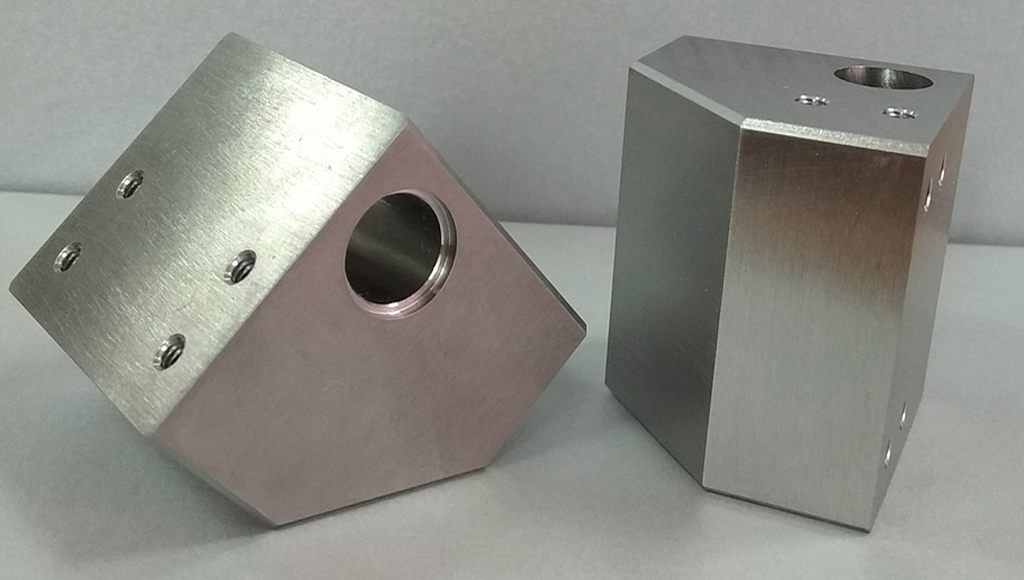

Other technological jigs

-

Seed holders;

-

Crucible supports;

-

Roller paths, roller conveyors;

-

Guide rails, rolls, shafts;

-

Drain bushings;

-

Baskets, grids, drip plates;

-

Covers, muffles, retort vessels;

-

Other items of different steel brands used for structures.

| Material |

Tungsten |

| Density, g/cm3 |

19.3 |

| Thermal conductivity, 25°СW/m•K |

167 |

| Thermal expansion coefficient, 25°С (10-6/К) |

4.67 |

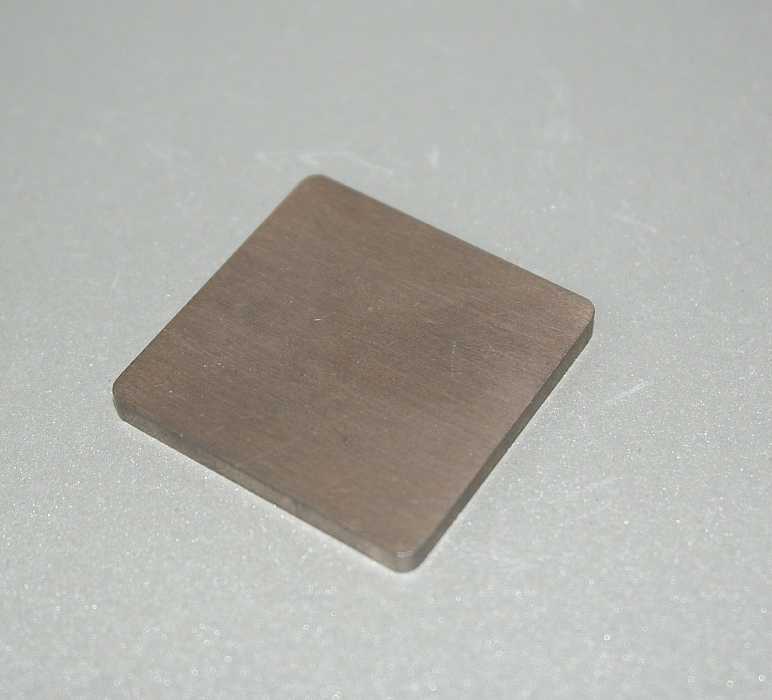

Tungsten boat. Welding of tungsten pieces

- Heat resistance;

- Thermal creep resistance;

- High elasticity modulus;

- Lowthermalexpansioncoefficient;

- Durability and strength;

- Corrosion resistance;

- Chemical inertness, resistance to aggressive agents;

| Material |

Tungsten |

| Density, g/cm3 |

19.3 |

| Thermal conductivity, 25°СW/m•K |

167 |

| Thermal expansion coefficient, 25°С (10-6/К) |

4.67 |

We supply tungsten boats (tungsten vaporizers) of different dimensions and shapes per Customer’s specification.

Products from tungsten-containing alloys

Properties:

-

High alloy density;

- High radiation resistance;

- High durability;

- High strength;

- Heat strength and heat resistance;

- Minimalcorrosionsensitivity;

- Available cost.

Application:

-

Parts for radioactivity logging devices;

- Storage vessels for radioactive agents;

- Protective shrouds;

- Collimators;

- Elements of non-destructive control hardware;

- Radiation-measuring and radiation control equipment etc.

Tungsten-copper

| Class | Composition (%), Cu | Composition (%), Impurities ≤ | Composition (%), W | Density, g/cm 3 ≥ | Hardness, НВ kgs/mm2 | Specific resistance, µΩ.cm ≤ | Flexural strength, MPa≥ |

| W50/Cu50 |

50±2.0 |

0.5 |

base |

11.85 |

115 |

3.2 |

- |

| W55/Cu45 |

45±2.0 |

0.5 |

base |

12.30 |

125 |

3.5 |

- |

| W60/Cu40 |

40±2.0 |

0.5 |

base |

12.75 |

140 |

3.7 |

- |

| W65/Cu35 |

35±2.0 |

0.5 |

base |

13.30 |

155 |

3.9 |

- |

| W70/Cu30 |

30±2.0 |

0.5 |

base |

13.80 |

175 |

4.1 |

790 |

| W75/Cu25 |

25±2.0 |

0.5 |

base |

14.50 |

195 |

4.5 |

885 |

| W80/Cu20 |

25±2.0 |

0.5 |

base |

15.15 |

220 |

5.0 |

980 |

| W85/Cu15 |

15±2.0 |

0.5 |

base |

15.90 |

240 |

5.0 |

1080 |

| W90/Cu10 |

10±2.0 |

0.5 |

base |

16.75 |

260 |

6.5 |

1160 |

Tungsten-nickel-iron

| Composition (%), Ni | Composition(%), Fe | Density, g/cm3≥ | |

| W90 |

7 |

3 |

16.85-17.25 |

| W92.5 |

5.25 |

2.25 |

17.15-17.85 |

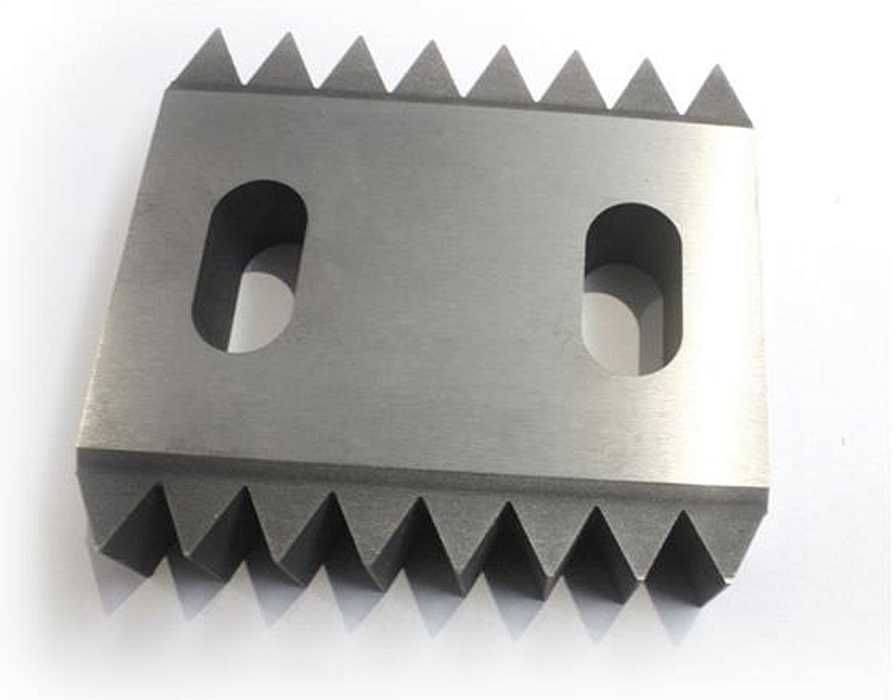

Tungsten carbide

| Marking | Density, g/cm3 | Hardness, HRA | Flexural strength, MPa |

| YG6X |

14.8-15.1 |

≥91 |

≥1420 |

| YG6 |

14.7-15.1 |

≥89.5 |

≥1520 |

| YG8 |

14.6-14.9 |

≥89 |

≥1470 |

| YG8.2 |

14.4-15.0 |

≥88 |

≥1450 |

| YG8L |

14.6-15.0 |

≥89 |

≥1450 |

| YG15 |

13.9-14.2 |

≥86.5 |

≥2060 |

| HK12 |

14.2-14.7 |

≥87.5 |

≥2100 |

| KY10 |

14.1-14.5 |

≥87.5 |

≥2060 |

| YG20 |

13.4-13.8 |

≥83.5 |

≥2480 |

| YG20C |

13.4-13.8 |

≥82 |

≥2480 |

| YG20D |

13.4-13.8 |

≥82 |

≥2300 |

| YSN30 |

13.9-14.9 |

≥87 |

≥1900 |

Alternative ratio or tungsten carbide and cobalt is possible, when so requested by Customer.