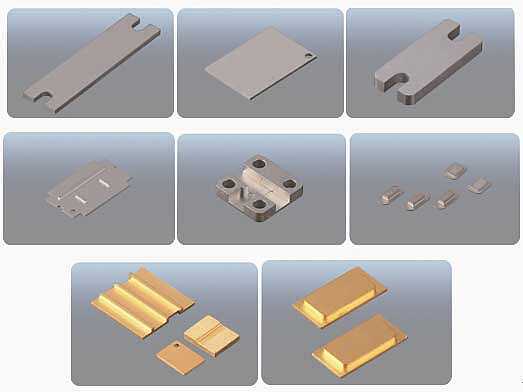

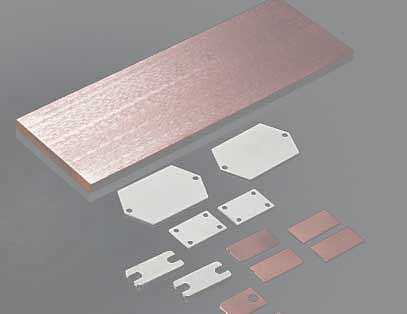

Molybdenum-containing alloys

Thanks to its refractory nature, heat and corrosion resistance tools production and chemical industry. Molybdenum alloys are also widely used in these industries.

Molybdenum-copper alloy comprises characteristics of its components, namely the high thermal conductivity, low thermal expansion coefficient low gassaturation. Being deprived of magnetic properties, its perfect functionality well-known for easy machining etc.

Due to lower (compared to that of tungsten) density molybdenum-copper alloy is easily machined and thus more suitable for mass production.

Molybdenum-copper

|

Class

|

Chem.composition (%), Mo

|

Chem.composition (%), Cu

|

Density, г/cm3 ≥

|

Thermal conductivity, 25°С, W/m·К

|

Thermal expansion coefficient, 25°С, (10-6/К)

|

|

Mo85Cu15 |

85±1 |

residue |

10 |

160-180 |

6.8 |

|

Mo80Cu20 |

80±1 |

residue |

9.9 |

170-190 |

7.7 |

|

Mo70Cu30 |

70±1 |

residue |

9.8 |

180-200 |

9.1 |

|

Mo60Cu40 |

60±1 |

residue |

9.66 |

210-250 |

10.3 |

|

Mo50Cu50 |

50±1 |

residue |

9.54 |

230-270 |

11.5 |

|

Mo40Cu60 |

40±1 |

residue |

9.42 |

280-290 |

11.8 |

The “NPO “GKMP” LLC suppliesa wide range of molybdenum-containing alloy sperCustomer’s drawings and considering Customer’s needs.