Molybdenum

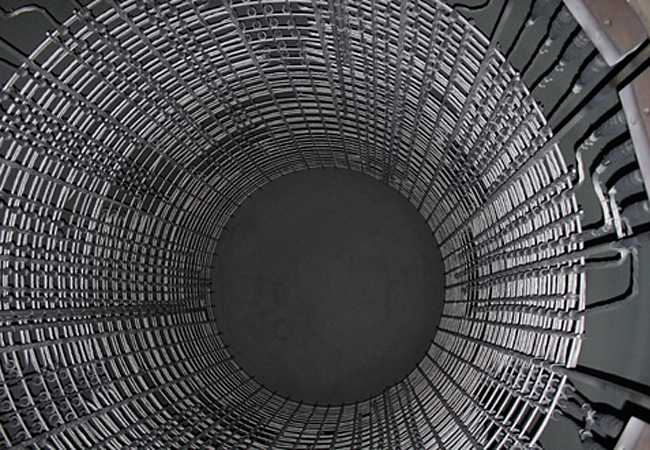

Molybdenum crucibles

Molybdenum is characterized by high elasticity modulus, high thermal resistance and low thermal expansion coefficient, as well as high corrosion resistance in melts and alkali vapors.

Refractory nature and heat strength of molybdenum (melting point is 2620ºC) define future properties of the end product, so molybdenum crucibles proven to be very efficient in vacuum and inert gases. Moreover, electric and chemical corrosionandoxidizing resistance at high temperatures make it possible to use molybdenum in aggressive media.

A crucible is produced as follows: molding by sintering, molding by lathwork, molding by turning. Due to the fact that a crucible should not interact with materials within, only high purity molybdenum is used for production.

Depending on the purpose, the molybdenum crucibles have the most diverse shapes and sizes: cone, ellipse, with a rounded edge, without a bottom, a boat, micro and industrial crucibles, wide crucibles, tall crucibles with a reinforced edge, etc.

Depending of the purpose molybdenum crucibles have different shape and dimensions: cone, ellipsis, chamfer-edgedcrucibles, bottomless, boats, micro-crucibles, widecrucibles, highcrucibleswithreinforcededgeetc.

Characteristics of molybdenum crucibles

|

Diameter, mm

|

Wall thickness, mm

|

Height, mm

|

|

30-50 |

0.3-10 |

<2000 |

|

50-100 |

0.5-15 |

<2000 |

|

100-150 |

1-15 |

<2000 |

|

150-300 |

1-20 |

<2000 |

|

300-400 |

1.5-20 |

<2000 |

|

400-500 |

2-30 |

<2000 |

The “NPO “GKMP” LLC supplies molybdenum crucibles including bowls and baths of different shapes and dimensions per Customer’s Specification.

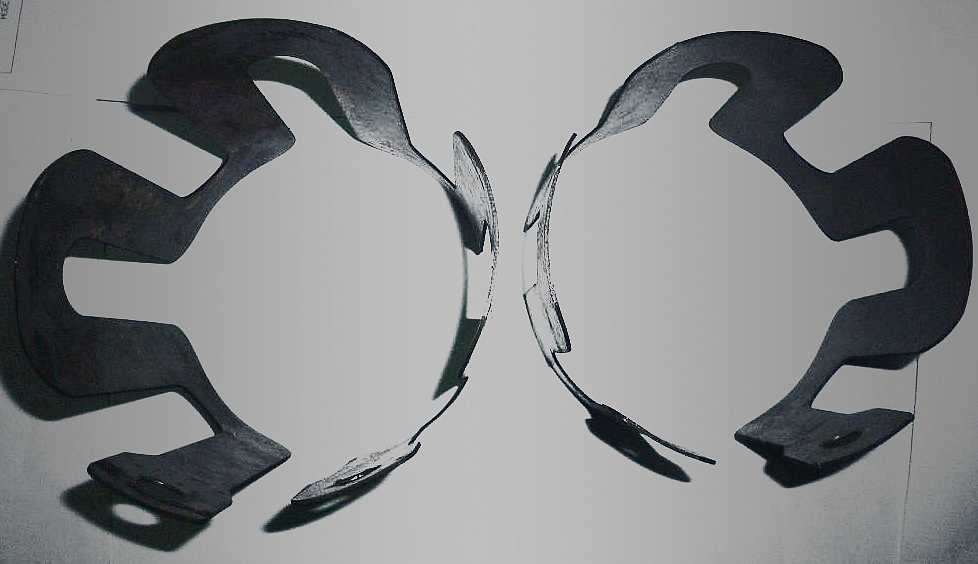

Molybdenum shrouds

Protective molybdenum shrouds have great heat resistance and mechanical strength; they are often used syonymously vacuum or hydrogen medium (at temperature of 1370°С.); its high corrosion resistance make it possible to use in aggressive environment.

The “NPO “GKMP” LLC proposes molybdenum protective shrouds of different shapes, design and complexity per Customer’s individual drawings.

| Material |

Molybdenum |

| Density, g/cm3 |

10.2 |

| Thermal conductivity, 25°СW/m•К |

138 |

| Thermal expansion coefficient, 25°С (10-6/К) |

4.90 |

Protective shrouds from molybdenum can be of any size or shape considering its anticipated purpose.

The “NPO “GKMP” LLC supplies protective shrouds from molybden umpire Customer’s drawings.

Molybdenum heaters

Molybdenum heaters are commonly used as part of high temperature furnaces: vacuum and hydrogenated acrylonitrile inductions intering furnaces with operating temperature above 2000°С, as long as they are peculiar with their operational reliability and high heat resistance. Heaters are irreplaceable for glass melting, sintering of powder materials, growing monocrystals etc.

The price of a molybdenum heater is conditioned by the complexity of its configuration, dimensions and additional requirements of the Customer.

The “NPO “GKMP” LLC supplies heaters of any configuration and sizeper Customer’s drawings.

Types of available heating elements by shape:

The “NPO “GKMP” LLC supplies molybdenum heaters of any size and kitting considering the purpose and anticipated application per Customer’s drawings.

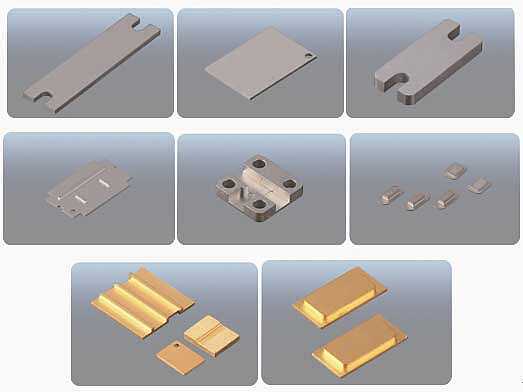

Other products and pieces from molybdenum

Molybdenum is several times surpassed by tungsten in mechanical strength, but is more machinable under pressure. Moreover, thanks to lower (compared with tungsten) density, molybdenum-based alloys have greater specific robustness (attemperaturebelow1370°С). Thepriceformolybdenummaybelowerthanthat of tungsten.

Molybdenum products and parts are quite widely used and highly demanded in various industries:

The “NPO “GKMP” Llc supplemental information foil, sheet, rod, circle, O-rings, beam,studs, tubes, ncluding those madeper Customer’s specification and needs.

|

Type, mm

|

Thickness, mm

|

Width, mm

|

Length, mm

|

|

foil |

>0.3 |

800 |

2000 |

|

molybdenum alloy sheet |

1-3 |

350 |

700 |

|

Type, mm

|

Diameter, mm

|

Length, mm

|

|

rod (max) |

110 |

2000 |

|

circle (max) |

20-600 |

6-45 |

O-rings, stems and studs

|

Diameter, mm

|

Wall thickness, mm

|

Lenght, mm

|

|

30-150 |

5-10 |

<1300 |

|

150-300 |

10-50 |

<1300 |

|

300-400 |

50-60 |

<1300 |

|

400-600 |

50-100 |

<1300 |

|

600-700 |

50-200 |

<1300 |

The “NPO “GKMP” LLC supplies an wide range of molybdenum products and piecesper Customer’s drawings.

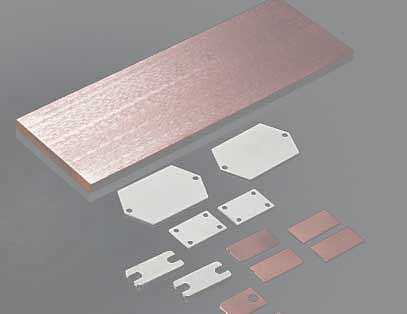

Molybdenum-containing alloys

Thanks to its refractory nature, heat and corrosion resistance tools production and chemical industry. Molybdenum alloys are also widely used in these industries.

Molybdenum-copper alloy comprises characteristics of its components, namely the high thermal conductivity, low thermal expansion coefficient low gassaturation. Being deprived of magnetic properties, its perfect functionality well-known for easy machining etc.

Due to lower (compared to that of tungsten) density molybdenum-copper alloy is easily machined and thus more suitable for mass production.

Molybdenum-copper

|

Class

|

Chem.composition (%), Mo

|

Chem.composition (%), Cu

|

Density, г/cm3 ≥

|

Thermal conductivity, 25°С, W/m·К

|

Thermal expansion coefficient, 25°С, (10-6/К)

|

|

Mo85Cu15 |

85±1 |

residue |

10 |

160-180 |

6.8 |

|

Mo80Cu20 |

80±1 |

residue |

9.9 |

170-190 |

7.7 |

|

Mo70Cu30 |

70±1 |

residue |

9.8 |

180-200 |

9.1 |

|

Mo60Cu40 |

60±1 |

residue |

9.66 |

210-250 |

10.3 |

|

Mo50Cu50 |

50±1 |

residue |

9.54 |

230-270 |

11.5 |

|

Mo40Cu60 |

40±1 |

residue |

9.42 |

280-290 |

11.8 |

The “NPO “GKMP” LLC suppliesa wide range of molybdenum-containing alloy sperCustomer’s drawings and considering Customer’s needs.