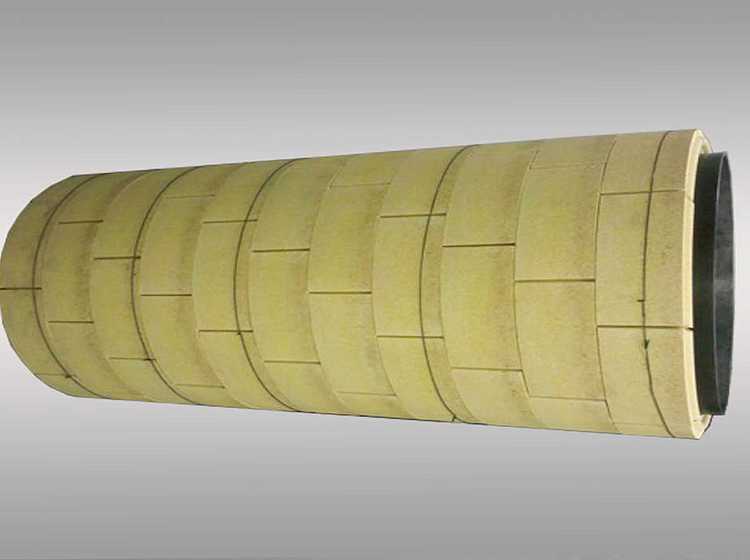

Zirconium dioxide ceramics

Products made of zirconium dioxide technical ceramics are chemically inert (do not react with aggressive agents).

Zirconium dioxide (ZrO2) has a unique set of properties, such as:

- High hardness;

- Perfect corrosion resistance;

- Low thermal conductivity;

- Crack resistance;

- Robustness at high temperatures.

The combination of these properties renders Zirconium dioxide ceramics irreplaceable for numerous industries (from high resistive parts to medicine).

Zirconium dioxide is used to obtain extra heat resistive products, heat resistive enamel, refractory glass, different types of ceramics, ceramic pigments, thermal protective coatings, catalyzers, cutters and abrasive materials. Recently zirconium dioxide is widely used in fiber optics and production of ceramics to be integrated in electronic devices.

Characteristics:

- Maintain robustness at high temperatures (melting point 2715 °С);

- High hardness;

- Corrosion resistance;

- Low thermal conductivity.

Application:

We supply zirconium dioxide products of different design per Customer’s individual drawings.

Basic properties of the material ZrO2 95%+ Y2O3 5%

| Density, g/cm3 |

6.03 |

| Open porosity, % |

0 |

| Vickers hardness |

1150 (HV0.5) |

| Elasticity modulus, GPa |

205 |

| Flexural strength, MPa |

1300 |

| Compressive strength, MPa |

3000 |

| Thermal conductivity at 20-100°С, W/mK |

2.0 |

| Thermal resistance |

280 (△ T °С) |

| Linear thermal expansion coefficient at 20-1000°С, 10-6К-1 |

10-11 |

| Volumetric specific resistance (20°С) |

≥1010 (Ω) |

| Maximal operating temperature |

1000 |

Material can be used with alternative percentage ZrO2 + Y2O3.

It is possible to use calcium oxide or magnesium oxide as stabilizer, if so requested by the Customer.

The “NPO “GKMP” LLC supplies zirconium dioxide products of different design per Customer’s individual drawings.