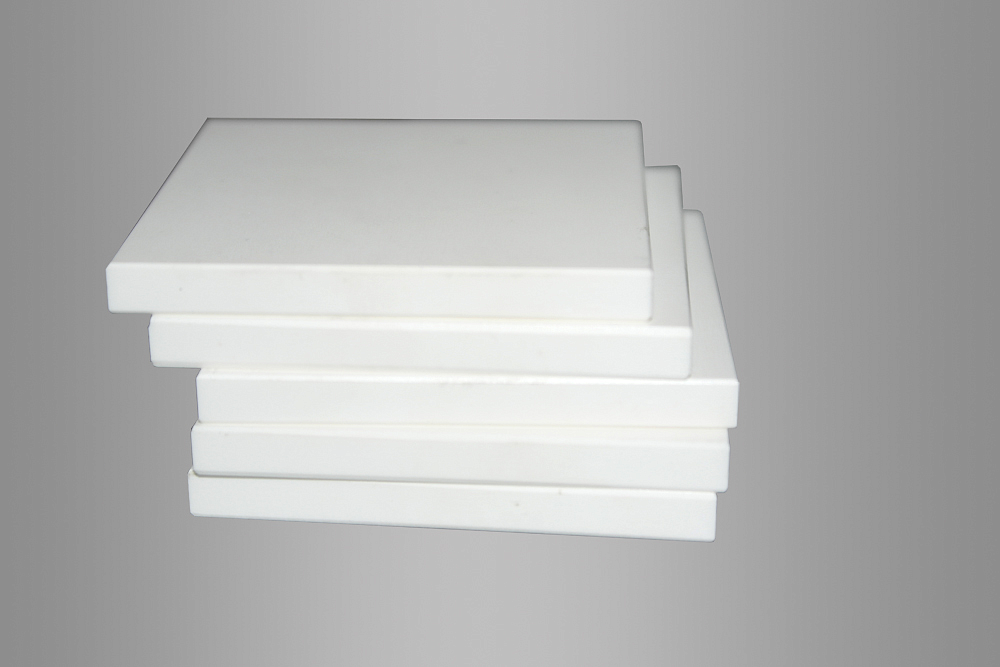

ZTA based ceramics

ZTA based ceramics

ZTA is a combination of alumina and 10-20% zirconium

ZTA properties:

- Additional hardness and viscosity compared to that of aluminum oxide;

- Better price that that of zirconium dioxide;

- High corrosion resistance;

- High fracture viscosity;

- High flexural strength.

Application:

- Insulators, sensors, piston bushings and pump components;

- Liquid supply system components;

- LED chip carriers.

The main characteristics of the material:

| ZrO, % |

20 |

| Al2O3+ZrO2, % |

30 |

| Density, g/cm3 |

≥4.00 |

| Water absorbed, % |

0 |

| Hardness, HV(GPa) |

1650 |

| Flexural strength, MPa |

400-500 |

| Compression strength, MPa |

2800 |

| Fracture viscosity, MPa m3/2 |

9.8 |

| Elasticity modulus, GPa |

310 |

| Maximal operating temperature, оС |

1450 |

| Sintering temperature, оС |

1650 |

| Thermal expansion coefficient, X10-6/oC |

8.2 |

| Thermal conductivity, W/m • K(25-300°С) |

9.8 |

- The “NPO “GKMP” LLC supplies ZTA products of different design per Customer’s individual drawings.

- Maximal operating temperature of ZTA products - 1450°С. ZTA is often used to produce insulators, sensors and pump components, fluid supply system components, casing and LED chips carriers.

Documents

Получить консультацию

Подробно расскажем о наших товарах, видах и стоимости доставки,

подготовим индивидуальное предложение для оптовых клиентов!

Задать вопрос

Подробно расскажем о наших товарах, видах и стоимости доставки,

подготовим индивидуальное предложение для оптовых клиентов!

Your name E-mail Phone

Your request

Sent