Vacuum furnaces for isostatic pressing

Vacuum furnaces for isostatic pressing

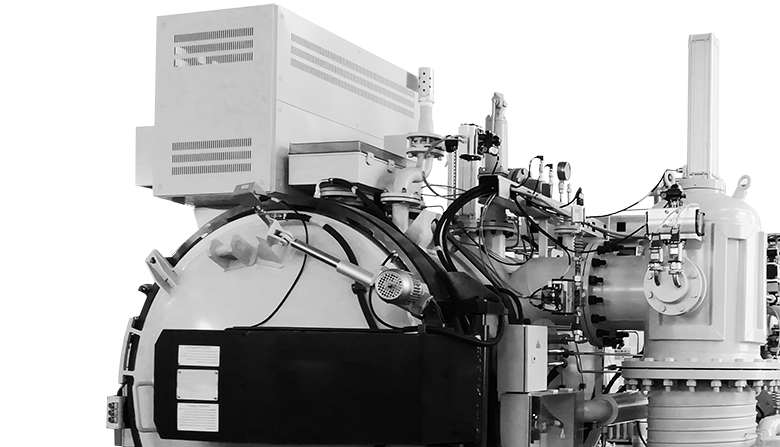

Vacuum furnace for pressing is a set-up designed to sinter ceramic and powder products by high pressure. Once processed, the robustness of a material is increased, so as its lifetime. This technique also results in reduced wearing-off of devices while their service life. The hardware is used for annealing and pressing of ceramics, sintered hard alloys and powder mixtures. Sintering is performed under high temperature in deep vacuum.

Vacuum furnace for pressing is a set-up designed to sinter ceramic and powder products by high pressure. Once processed, the robustness of a material is increased, so as its lifetime. This technique also results in reduced wearing-off of devices while their service life. The hardware is used for annealing and pressing of ceramics, sintered hard alloys and powder mixtures. Sintering is performed under high temperature in deep vacuum. The main selection criteria of vacuum furnaces are:

- Efficiency;

- Power;

- Dimensions;

- Size of the chamber;

- Discharge level;

- Operating temperature;

- Heater type.

Hot pressing furnace ensures the treatment of different compositions and types of materials, easy to use and equipped with automated control system that ensures a safe operation and sends a sound signal in case of overheating or lack of water.

Isostatic pressing is performed using the special hardware – an isostatic press. This device distributes isostatic (equally in all directions) pressure through various media that affect the material. Isostatic presses are applied for uniform squeezing of powders in order to get a workpiece or an item. This is the most frequently used type of furnaces for isostatic pressing. Apart from that, furnaces are additionally equipped with auxiliary vacuum, gas and cooling system.

Our company is specialized in selection, delivery, design and production of the vast range of vacuum equipment, including high-quality hot-pressing furnaces.

- Experience – In-the-house production – Comprehensive product line – Guarantee and maintenance – Delivery

Documents

Ordering products/services

Получить консультацию

Подробно расскажем о наших товарах, видах и стоимости доставки,

подготовим индивидуальное предложение для оптовых клиентов!

Your name E-mail Phone

Your request

Задать вопрос

Подробно расскажем о наших товарах, видах и стоимости доставки,

подготовим индивидуальное предложение для оптовых клиентов!

Your name E-mail Phone

Your request

Sent