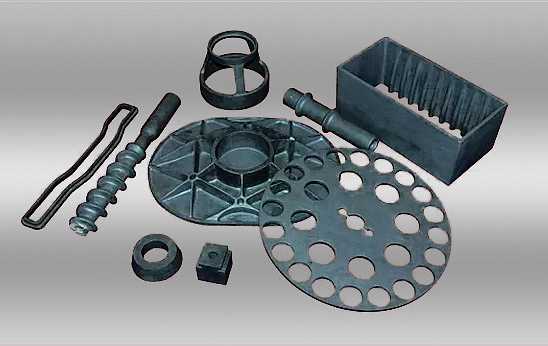

Silicon carbide ceramic products

Silicon carbide (SiC) ceramics ensures high thermal resistance and high operational characteristics. Among the key benefits one can name resistance to temperature gradient, high corrosion resistance and stable dimensions.

Silicon carbide ceramics was widely adopted in automobile production and aerospace as abrasive semiconductor structural high temperature material for production of engine elements and thermal facilities, as well as other electronics.

Application:

- Fittings and structural elements of high temperature furnaces;

- Nozzles for various purposes, burner tops, retort vessels;

- Jackets for thermal couples, heat-resistive tubes;

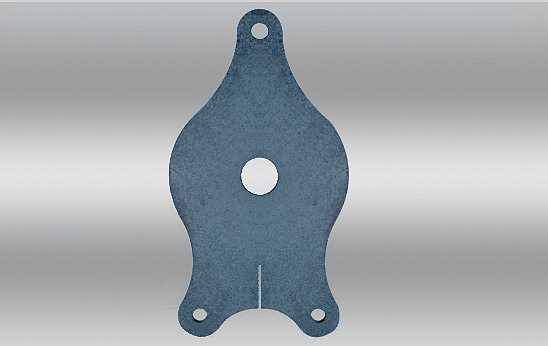

- Crucibles, barrels, casings of different configuration;

- Friction couple;

- Heaters;

- Elements of thermal combustion facilities etc.

Benefits:

- High mechanical robustness;

- High hardness;

- Resistance to thermal shock;

- High durability when exposed to abrasive stress and high temperatures;

- Resistance to corrosion and oxidizing;

- High resistance to exposure of aggressive media;

- High electric conductivity;

- Low thermal expansion coefficient = high thermal resistance, stable geometry;

- High chemical resistance.

The “NPO “GKMP” LLC proposes silicon carbide ceramic parts of different design (SSiC, SiSiC, RSiC and OSiC) per Customer’s requirements.

Silicon infiltrated silicium carbide (SiSiC)

| Operating temperature, 0С |

1380 |

| Density, g/cm3 |

≥3.02 |

| Apparent porosity, % |

≤0.1 |

| Flexural strength, MPa |

250(20°С) 280 (1200°С) |

| Elasticity modulus, GPa |

300(1200°С) 330(20°С) |

| Thermal conductivity, W/m·K |

45(1200°С) |

| Strength |

13 |

| Resistance to acids and alkali |

high |

Sintered silicon carbide (SSiC)

| Free silicon, % |

<0.1 |

| Silicon carbide, % |

≥99 |

| Poured density, g/cm3 |

3.1-3.15 |

| Vickers hardness, НV |

2500 |

| Rockwell hardness, НRA |

94 |

| Open porosity, % |

<0.2 |

| Compressive strength, MPa |

>3000 |

| Flexural strength, MPa |

>400 |

| Elasticity modulus, GPa |

410 |

| Thermal conductivity, W/m·K |

100-120 |

Recrystallized silicon carbide (RSiC)

| α- SiC, % |

98.5 |

| Maximal operating temperature, oC |

1650 |

| Porosity, % |

15 |

| Poured density, g/cm3 |

2.60-2.74 |

| Compressive strength, MPa |

>600 |

| Flexural strength, MPa |

90-100 |

| Young modulus, ГПа |

240 |

| Thermal conductivity, W/m·K |

24 |

Oxide-bonded silicon carbide (OSiC)

| SiC, % |

≥90 |

| Maximal operating temperature, oC |

1550 |

| Open porosity, % |

7-8 |

| Poured density, g/cm3 |

2.75 |

| Compressive strength, MPa |

≥1300 |

| Tensile strength at ambient temperature , MPa |

≥500 |

Nitride-bonded Silicon carbide (NSiC)

| SiC content, % |

≥75 |

| Si3N4 content, % |

≥21 |

| Fe2O3 content, % |

≤0.5 |

| Maximal operating temperature, °С |

1550 |

| Porosity, % |

≤15 |

| Density, g/cm3 |

2.6-2.7 |

| Flexural strength, MPa |

≥180 |

| Flexural strength (20°С), MPa |

≥45 |

| Flexural strength (1200°С), MPa |

≥50 |

| Thermal conductivity (800°С), W/m·K |

≥18 |

| Thermal conductivity (1200°С), W/m·K |

≥14 |

The “NPO “GKMP” LLC proposes silicon carbide ceramic parts of different design (SSiC, SiSiC, RSiC and OSiC) per Customer’s drawing and dimensions required.