Vacuum furnace is a specialized thermal equipment that is designed for thermal treatment in non-oxidizing environment and/or in vacuum. Among definitive advantages of these furnaces one can name no significant deformations, repeatable treatment results, optimal resistance and robustness of the pieces manufactured. Moreover, furnaces enable a wide range of thermal treatment techniques that can be performed using different devices.

We produce industrial and laboratory furnaces. Our product line includes a wide range of standard furnaces, as well as those fit for customized sizes of the working area should Customer so require.

Vacuum furnaces are widely used in aerospace industry, medicine, machinery, car production, metallurgy, electronics, chemicals to sinter ceramics and metallic powder.

Our company is an expert in selection, delivery, design and production of a wide range of vacuum equipment, including furnaces to sinter metallization paste in ceramics, creation of glass and metal alloys, furnaces for tempering and removal of the binder, vacuum furnaces for annealing, tempering furnaces, vacuum retort furnaces, vacuum compression furnaces, vacuum arc furnaces, vacuum chambers, nitration vacuum furnaces, vacuum reduction furnaces, vacuum welding furnaces, lower-loading vacuum furnaces, resistance vacuum furnaces, sintering vacuum furnaces, vacuum melting furnaces, vacuum electron arc furnaces, high welding temperature furnaces, water tempering furnaces etc.

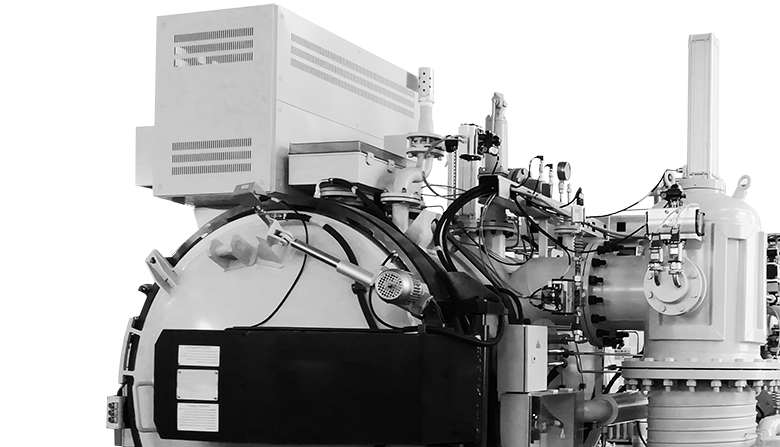

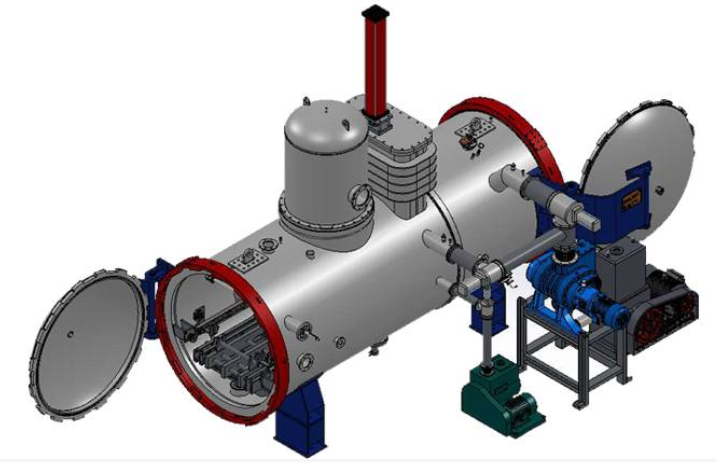

Gas quenching vacuum furnaces

Vacuum furnaces that allow quenching in inert gases are in high demand and considered as the most suitable option from the entire scope of thermal treatment hardware. Such equipmentensures theprocessing of stainless steel, titanium alloys as well as materials subject to higher quality and robustness requirements.

Vacuum furnaces that allow quenching in inert gases are in high demand and considered as the most suitable option from the entire scope of thermal treatment hardware. Such equipmentensures theprocessing of stainless steel, titanium alloys as well as materials subject to higher quality and robustness requirements.

This type of furnace is widely used in production of motors, drives, electric stations etc.;else theyare applied in aircraft construction, machinery and especially in metallurgy. Vacuum furnaces for gas quenching have numerous applications and can enhance capacities of quite any production. Apart from that vacuum furnaces are frequently used for laboratory experiments and to test materials of any kind.

Vacuum furnaces are fit for thermal treatment of metals and alloys.

Our company has a vast experience in selection, delivery, design and production of a wide range of vacuum equipment, including high-quality gas quenching vacuum furnaces.

- Experience – In-the-house production – Comprehensive product line – Guarantee and maintenance – Delivery

Vacuum annealing furnace

Vacuum annealing furnace enables to upgrade some properties of a material and thus improve their quality by creating a more homogeneous structure. This operation is performed by heating and further cooling down of a workpiece. Vacuum furnaces, unlike any other annealing equipment, enable to perform this procedure without having the metal oxidized.

Vacuum annealing significantly increases the elasticity of a material. For example, such process can many times improve the titanium impact viscosity

Furnaces are designed to anneal and stabilize items from instrumental, sealing, speed-cutting, refractory and stainless steels, magnetic materials, non-ferrous alloys etc.

The up-do-date technologies ensures the best quality of thermal treatment and perfectly smooth surface.

We can propose furnaces to fitany non-standard dimensions of the working area per Customer’s specification.

Vacuum furnaces are good for thermal treatment of metals and alloys.

Our company has a vast experience in selection, delivery, design and production of a wide range of vacuum equipment, including high-quality gas quenching vacuum furnaces.

- Experience – In-the-house production – Comprehensive product line – Guarantee and maintenance – Delivery

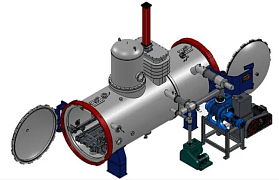

Vacuum tempering furnace (retort furnace)

Vacuum tempering furnace is a specialized hardware that recrystallize alloys and dissolve martensite (special structure peculiar to hardened metals, a microlevel of a needle-shaped or rail type). As a rule, a retort furnace has a sealed retort; heaters are mounted outside the main element. The neutral gas is either supplied inside or discharged, depending on the type of the treatment performed. Such design of the furnace does not involve any thermal insulation of water jacket type.

Vacuum tempering furnace is a specialized hardware that recrystallize alloys and dissolve martensite (special structure peculiar to hardened metals, a microlevel of a needle-shaped or rail type). As a rule, a retort furnace has a sealed retort; heaters are mounted outside the main element. The neutral gas is either supplied inside or discharged, depending on the type of the treatment performed. Such design of the furnace does not involve any thermal insulation of water jacket type.

“NPO “GKMP” LLC offers furnaces to fit non-standard dimensions of the working area per Customer’s specification.

Thanks to its efficiency and competitive price vacuum tempering furnaces are widely used in different industries: such furnaces are frequently used to produce pieces subject to high loads. Furthermore, this type of furnace is engaged in aviation and car construction industry. As for the modern metal casting factories, they simply cannot exist without vacuum tempering furnaces.

Advantages of vacuum tempering furnace

The vacuum tempering furnaces have the following advantages:

- Environmental security;

- Surfaces of the pieces treated are free from any damage and contamination;

- Relatively low power consumption;

- High efficiency;

- Robustness and reliability;

- Equipped with an embedded temperature control device to maintain and adjust proper thermal treatment mode;

- Equipped with information display for convenient process data surveillance;

- Highly automated operations;

- Reliable security system that sends alarm signal in case of emergency;

- Simple and reliable design;

- Easy installation, commissioning and maintenance;

- Competitive price.

Vacuum furnaces are fit for thermal treatment of metals and alloys.

Our company has a vast experience in selection, delivery, design and production of a wide range of vacuum equipment, including high-quality vacuum tempering furnaces.

-Experience – In-the-house production – Comprehensive product line – Guarantee and maintenance – Delivery

Vacuum heat treatment furnaces

Vacuum heat treatment furnaces are the most efficient onesthat enable thermal treatment of pieces made from different metals and alloys. It is thermal vacuum treatment that ensures the best quality of workpieces thus processed. Moreover, the processing cycle is shorter in comparison with other hardware for thermal treatment. Our company is a renowned manufacturer of thermal vacuum furnaces and is ready to offer the wide range of thermal vacuum furnaces with various properties.

Vacuum heat treatment furnaces are the most efficient onesthat enable thermal treatment of pieces made from different metals and alloys. It is thermal vacuum treatment that ensures the best quality of workpieces thus processed. Moreover, the processing cycle is shorter in comparison with other hardware for thermal treatment. Our company is a renowned manufacturer of thermal vacuum furnaces and is ready to offer the wide range of thermal vacuum furnaces with various properties.

Furnaces for heat treatment of metals and alloys

Furnaces for powder metallurgy

Furnaces for metallurgy

Our company is an expert in selection, delivery, design and production of the vast range of vacuum equipment, including high-quality vacuum thermal treatment furnaces.

-Experience – In-the-house production – Comprehensive product line – Guarantee and maintenance – Delivery

Vacuum furnaces for isostatic pressing

Vacuum furnace for pressing is a set-up designed to sinter ceramic and powder products by high pressure. Once processed, the robustness of a material is increased, so as its lifetime. This technique also results in reduced wearing-off of devices while their service life. The hardware is used for annealing and pressing of ceramics, sintered hard alloys and powder mixtures. Sintering is performed under high temperature in deep vacuum.

Vacuum furnace for pressing is a set-up designed to sinter ceramic and powder products by high pressure. Once processed, the robustness of a material is increased, so as its lifetime. This technique also results in reduced wearing-off of devices while their service life. The hardware is used for annealing and pressing of ceramics, sintered hard alloys and powder mixtures. Sintering is performed under high temperature in deep vacuum. The main selection criteria of vacuum furnaces are:

- Efficiency;

- Power;

- Dimensions;

- Size of the chamber;

- Discharge level;

- Operating temperature;

- Heater type.

Hot pressing furnace ensures the treatment of different compositions and types of materials, easy to use and equipped with automated control system that ensures a safe operation and sends a sound signal in case of overheating or lack of water.

Isostatic pressing is performed using the special hardware – an isostatic press. This device distributes isostatic (equally in all directions) pressure through various media that affect the material. Isostatic presses are applied for uniform squeezing of powders in order to get a workpiece or an item. This is the most frequently used type of furnaces for isostatic pressing. Apart from that, furnaces are additionally equipped with auxiliary vacuum, gas and cooling system.

Our company is specialized in selection, delivery, design and production of the vast range of vacuum equipment, including high-quality hot-pressing furnaces.

- Experience – In-the-house production – Comprehensive product line – Guarantee and maintenance – Delivery

Vacuum sintering furnaces

Vacuum sintering furnace is a high temperature equipment designed for thermal treatment of glass workpieces, powder metals and devices produced by metal injection molding. The sintering process involves induced gas circulation with inert properties.

Vacuum sintering furnace is a high temperature equipment designed for thermal treatment of glass workpieces, powder metals and devices produced by metal injection molding. The sintering process involves induced gas circulation with inert properties.Sintering hardware involves different modification of furnaces either with nominal treatment characteristics, or with additional ones. The catalogue enlists products different in dimensions and kitting enabling to select the model best fit for any specific production conditions. One can buy sintering vacuum furnaces at available price on the company’s website depending on required performances and dimensions.

Vacuum furnaces are fit for thermal treatment of metals and alloys.

Our company is specialized in selection, delivery, design and production of the vast range of vacuum equipment, including high-quality sintering furnaces.

-Experience – In-the-house production – Comprehensive product line – Guarantee and maintenance – Delivery

Vacuum oil quench furnaces

Vacuum oil quench furnaces is designed for thermal treatment of pieces that cannot be quenched in inert gases.

Vacuum oil quench furnaces is designed for thermal treatment of pieces that cannot be quenched in inert gases.For example, one can take low-alloyed steel pieces for which the proper cooling speed is essential. Vacuum treatment ensures the highest quality of a piece so this is the reason why vacuum furnaces are widely used in different industries.

Vacuum furnaces are best fit for thermal treatment of metals and alloys.

Our company is specialized in selection, delivery, design and production of the vast range of vacuum equipment, including high-quality furnaces for oil hardening.

-Experience – In-the-house production – Comprehensive product line – Guarantee and maintenance – Delivery

Furnaces for nitriding, carbonization and carbonitriding

Furnaces for nitriding are devices that diffuse nitrogen atoms on outer surfaces of metallic pieces in order to increase their strength. Such technology is used for treatment of aluminum, titanium, molybdenum, low-carbon and low-alloyed steels. Such furnaces have peculiar performances, dimensions and volume of the operating chamber, as well as the power and ultimate pressure level. These parameters are crucial for nitriding of different metallic pieces.

Usually these furnaces are applied in production of cogs, crankshafts and distribution shafts, valve parts, pressure casting elements, swages, fire arm pieces and mold tools.

Our company is an expert in selection, delivery, design and production of the vast range of vacuum equipment, including high-quality furnaces for vacuum nitration.

-Experience – In-the-house production – Comprehensive product line – Guarantee and maintenance – Delivery