Tungsten electric heaters

Tungsten electric heaters

Tungsten heating elements are rightfully considered as the most suitable for metal melting. Tungsten heaters can efficiently operate at the temperature of 3000ºC due to their immunity to oxidizing at high temperatures and have substantial temperature stress (namely resistance to physical damage while heating) and heat resistance (immunity to aggressive environment when heated state). The shape and configuration of a tungsten heater depends on its purpose.

Tungsten heating element is a source of heat of the machine for monocrystal growing. Highmelting temperature and corrosion resistance render tungsten heaters crucial for crystal quality control.

Among definite benefits of tungsten one can name high operating temperature (in comparison with composite materials), ability to maintain high temperatures while prolonged outgassing period (in time). The maximal operating temperature of the tungsten heater directly depends on thickness of its body plates and on chemical composition of the operating medium inside the furnace.

Shapes or heaters available:

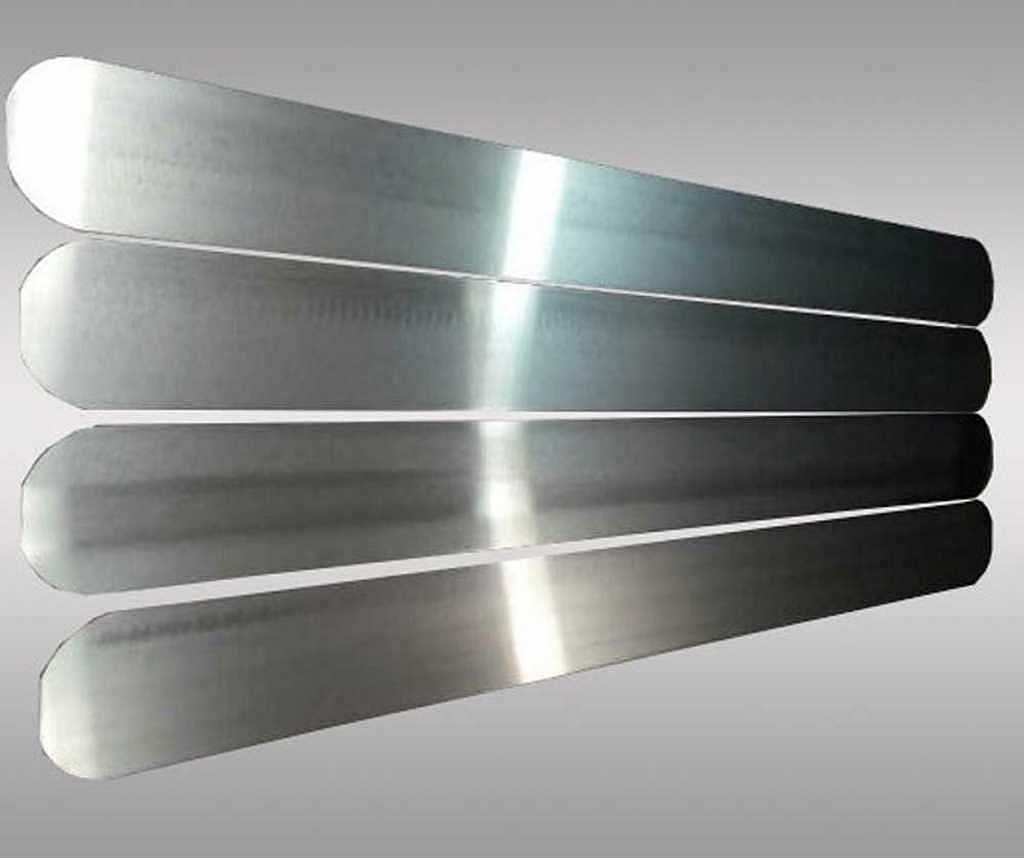

Band

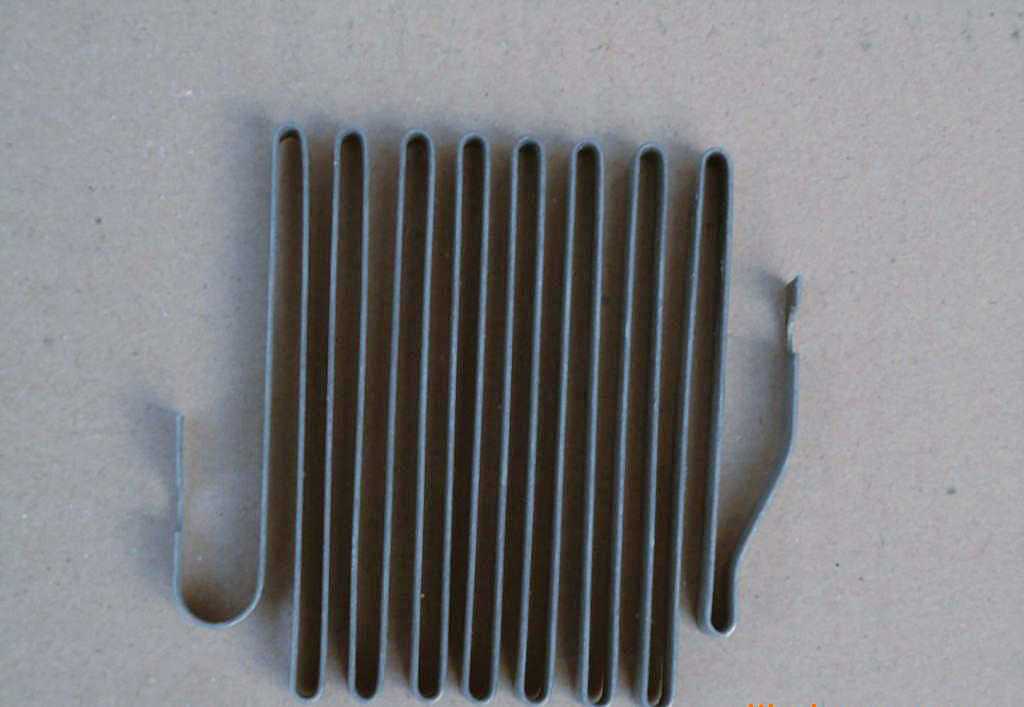

Spiral

Circular

Flat heaters have higher efficiency so basically, they are involved in complex tasks such as heating of hard surfaces (marble, granite etc.). The heating is carried out using resistive wire.

Band heates are commonly known as all-purpose devices used as part of flat surfaces with high thermal conductivity. The heating is based on contact at maximal power of 9W within 1 cm.

Spiral heaters are used for quality thermal exchange within limited space.

Circular heaters are often used to replace standard heating elements to increase service life of industrial hardware.

Tungsten heaters can be provided in any shape or dimensions depending on its anticipated application.

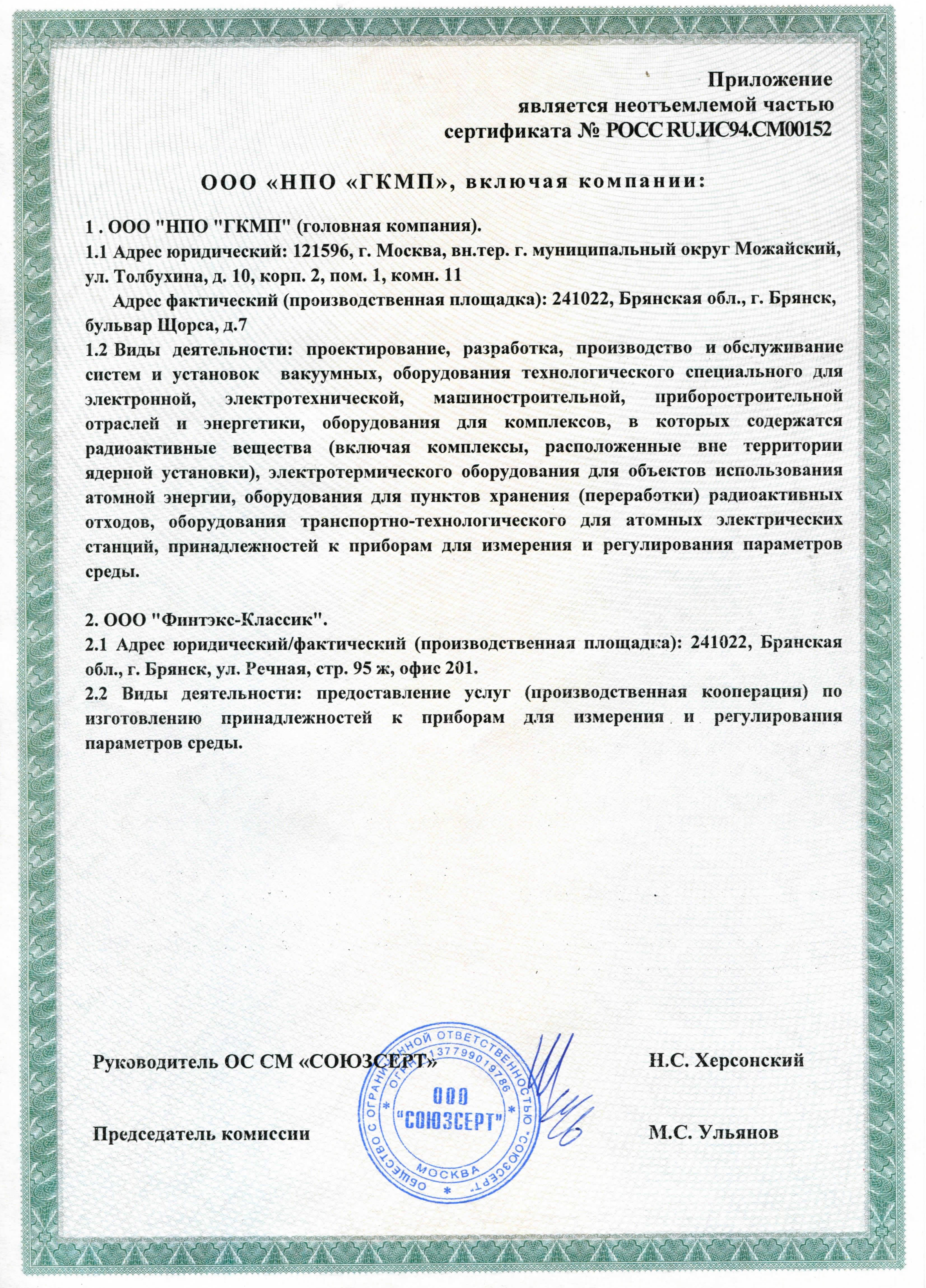

Documents

Получить консультацию

Подробно расскажем о наших товарах, видах и стоимости доставки,

подготовим индивидуальное предложение для оптовых клиентов!

Задать вопрос

Подробно расскажем о наших товарах, видах и стоимости доставки,

подготовим индивидуальное предложение для оптовых клиентов!

Your name E-mail Phone

Your request

Sent