Thermal treatment

Our company proposes a wide range of thermal treatment of metal pieces of various shapes and design performed in chamber furnaces and in batch-type resistance furnaces.

Thermal treatment alters metal properties in order to meet specific production needs.

Most commonly thermal treatment improves stability of workpieces subject to extreme loads and require impact strength.

Types of metal processing

Gas cementing

Max. temperature, ОС

950

Max. Operating volume, mm

700

Max. length, mm

1700

High temperature (800-950°C) and continuous exposure time (from few hours to few full days) enable carbon to penetrate the outer layer of the metal and thus generate iron carbides that improve robustness and durability of a piece. Gas cementing has a number of benefits compared with other method of chemical and thermal treatment. Firstofall, itensures homogenous carbon saturation on the entire piece surface enabling to obtain higher hardness and durability without any cracks or pores whatsoever. Secondly, this method decreases treatment time and energy costs alike.

Quenching, annealing, quenching in periodic furnaces

Max. temperature, ОС

950

Max. operating pressure

800

Width, mm

Height, mm

500

Length, mm

2000

These processes improve metal properties, namely strength, hardness and impact strength. Annealing relieves stress in metal and improve its plasticity. One of the key benefits of annealing in batch-type furnaces is more accurate control of temperature and heating time. These efforts ensure production of better quality and more reliable pieces with required characteristics. Moreover,batch-type furnace can be more convenient and efficient than other annealing facilities.

Quenching, annealing, quenching in shaft and chamber-type furnaces

Max. temperature, ОС

950

Max. operating pressure

1200

Diameter, mm

Length, mm

1900

Apart from that, production capacities may benefit from shaft and chamber furnaces for metal treatment. Such furnaces may heat up metal to reach high temperatures and then cool it down. Metal is treated in shaft and chamber furnaces at high temperatures enabling to reach high hardness and strength of metal. Shaftfurnacesareusedtotreatlargevolumeofmetal, and chamber furnaces – for more accurate treatment of small pieces.

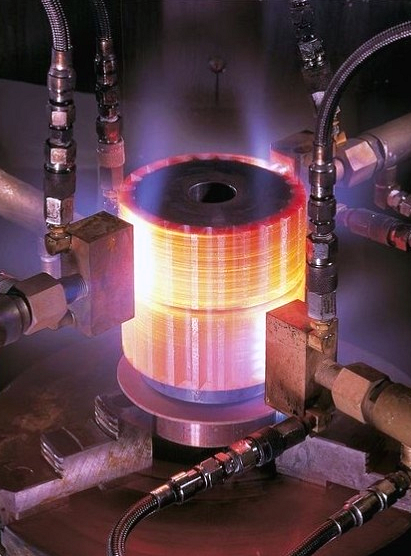

UHF-brazing, milling, quenching

Power generator, kw

100

MHz

0066

For production purposes, UHF-brazing is used to connect pieces from different metals and alloys. This brazing technique enables to produce a stiff and leak-proof connection that is highly resistive to corrosion and mechanical stress. UHF-brazing involves specific facilities that ensure accurate control of heating temperature and brazing time. The final product demonstrated high quality and reliability that does not require additional treatment. This type of thermal treatment enables to produce high quality and robust couplings fit to withstand high stresses and temperature.

Project implementation

- Acceptance

- Rating

- Analysis

- The deal

- Preparation

- The process

- Delivery

Acceptance and evaluation: at this stage all materials and hardware necessary for further implementation of the project are accepted. Moreover, quality and conformity assessment is made to make sure that the project is in line with requirements.

Analysis and transaction: this stage covers analysis of all data and materials, as well as transactions and agreements to be entered into between suppliers and contractors.

Preparation and production flow: this stage includes preparation of all required documents and schedules related to the project. The released product or services rendered shall be in accordance with the requirements of the project.

Commissioning and completion of the project: at the last stage the project is handed over to the customer, the works performed are subject to quality inspection, possible defects are rectified, if any. After that the project is considered completed and ready for use.

Types of furnaces

Shaft furnace

Highly efficient for treatment of large pieces. The furnace is used for annealing, tempering, quenching, stabilization of non-ferrous metals.

Vacuum furnace

Ensures highly accurate treatment of copper, construction steel, titanium alloys

Batch-type bell furnace

This type of furnace is fit for homogeneous heating, leak proofness and quick replacement of treated pieces. As long as there are no dusty materials inside the chamber, and considering the new method to treat surfaces enable to perform extra-high purity processes.