Сonveyor belt furnaces

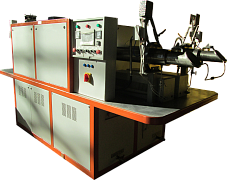

Conveyor belt electric furnace - electric resistance furnace of a continuous type with a continuously or periodically moving conveyor.

The main advantage of conveyor electric furnaces is the ability to process large volumes of products in a protective or protective-reducing atmosphere. This type of furnace is perfectly suited for serial and mass production. LLC NPO GKMP produces conveyor furnaces with a direct and curved (humpback) type of channel.

Conveyor electric furnaces leaky, with a partially controlled atmosphere, continuous operation.

The main advantages of conveyor furnaces:

- the possibility of continuous operation in several shifts;

- processing of large batches of products in a continuous process;

- the possibility of implementing several technological operations in one cycle;

- simplicity in service and repair;

- modular design.

Scope: mass production of ceramic substrates, metal recovery, sintering of the same type of products, etc.

Pusher-type furnaces

Functionality: It is used for annealing of parts, sintering of an electroplating in the protective and reducing environment of hydrogen at the set temperature.

Functionality: It is used for annealing of parts, sintering of an electroplating in the protective and reducing environment of hydrogen at the set temperature.

Type of furnace: two-bell pusher type hydrogen furnace — a continuous furnace through which heated products are transported by pushing them through the heating chambers using an electric pusher.

Main advantages:

- the possibility of heat treatment of small batches of products;

- high percentage of suitable products, reproducibility of the process;

- the flexibility of the process, the ability to select the optimal modes;

- resourcesaving.

|

The number of working positions (heating chambers), pcs |

2 |

|

The working space of the chamber (muffle), mm, not less than: diameter length |

100 1000 |

|

Working environment inside the furnace nitrogen hydrogen |

(-15-20оС ) (-50оС ) |

|

Gas consumption, m3 / h, no more nitrogen hydrogen |

0.5 0.5 |

| Nitrogen pressure at the system input, kPa, no less than |

5 |

| Hydrogen pressure at the system input, kPa, no less than |

3 |

| Cooling water flow, m3/h, no more than |

1.5 |

| Water pressure at the water-cooling system input, Pa (kg*s/sm2), no less than |

0.3*106 (3) |

| Maximum working environment temperature, °С |

1400 |

| Maximum time limit in accordance with maximum temperature, min |

5 - 20 30 - 60 |

| Temperature maintenance precision, not worse than, °С |

±10 |

| Electrical power consumption, no more than, kW |

40 |

| Heating type |

resistive |

| Heater material |

molybdenum |

Total dimensions, mm, no more than length width high |

3400/3700 1300/1400 1750 |

| Weight, kg, no more than |

3000 |