Electric resistance furnace - a device (equipment) designed for non-contact transfer of thermal energy from a heating element to a heated object in a closed volume.

A distinctive feature of the use of resistance chamber electric furnaces produced by NPO GKMP LLC is a low temperature zone gradient and high purity of the medium inside the chamber.

Chamber electric furnaces are batch furnaces.

Chamber electric furnaces are divided into the following groups:

- According to the design of the chamber:bell-type, shaft.

- On the environment inside the chamber: vacuum, gas-filled.

The main advantages of bell furnaces:

- high effective

- the possibility of processing small batches of products;

- resource saving and energy saving;

- process flexibility;

- the ability to select the optimal processing conditions;

- a wide range of technological applications.

Scope: especially clean processes in the manufacture of electronic equipment, soldering in a protective atmosphere, heat treatment of precision parts, recovery of metal powders, etc.

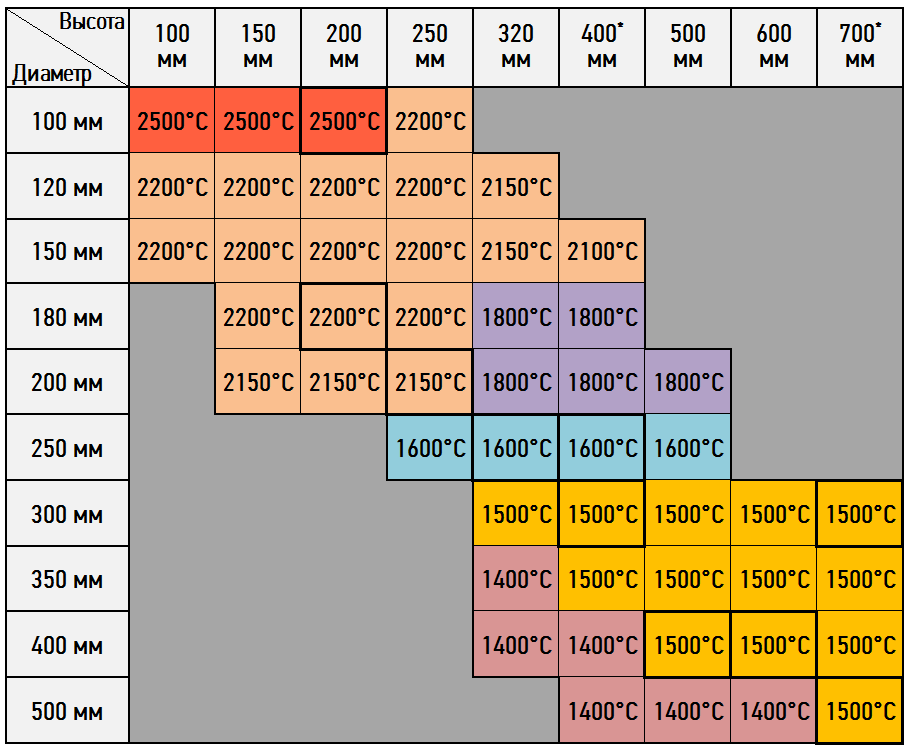

Standard dimensions of the working area and maximum temperatures:

*There are standard versions of two-bell furnaces with a working area height of 380 mm (2.250x380-1200) and one-bell furnaces with a lowering hearth bottom with a working zone height of 710 mm (1.500x710-1300). It is also possible to manufacture furnaces with non-standard design of the working area, with any dimensions and increased maximum operating temperature.

To ensure comfortable operation and maintenance, it is recommended that furnaces with a working zone diameter of 300 mm or more be manufactured with heaters fixed motionless relative to the bell. It is recommended that furnaces with a diameter of more than 300 mm be manufactured with a fixed hood (a lowering hearth). To minimize the gradient of the temperature field of the working space, it is recommended to choose the height of the working area that exceeds the diameter of the working area by 20 ... 40%.

Short form for ordering bell-type furnaces of periodic action:

APVDД N.DDDхHHH–TTTT

APVD, APGV, PEV – registered trademarks of furnaces manufactured by NPO GKMP LLC;

N – is the number of bells (1 or 2);

DDD – maximum diameter of the working area;

HHH – maximum height of the working area;

TTTT – maximum temperature of the working area.

Bell lift-off type furnaces with stationary heating systems

The structural feature of this type of furnace is the stationary position of the heating system, which ensures the best maintainability and convenient maintenance of the heating system with frequent use of equipment. Stationary installed heaters provide the best visual control of the working area when installing cages with products, which allows to increase the percentage of suitable products and make the process as manageable as possible. After the automated lifting, the hood is pulled to the side and the charge of the cage with products is loaded vertically.

The heating elements can be of a cylindrical and strip type, from high-temperature resistance alloys (nichrome, eurofechral, kanthal A1), molybdenum, tungsten, tungsten-rhenium alloy, the installation of an all-welded heater is possible. Such a wide range of materials used allows you to create a furnace with a precise atmosphere, suitable for most industrial processes. The absence of dusty materials in the heating chamber, as well as a special method of surface treatment, allows ultra-pure processes in furnaces.

| Chamber quantity, items |

1 или 2 |

| Type of chambers |

cylindrical, vertically oriented |

|

Inner dimensions of chamber: diameter, mm height, mm |

80-250 100-380 |

|

Temperaturein the working chamber,оС:

control thermocouples ХА (K) or НН (N) control thermocouples PP (S) or PR (B) control thermocouples BP (A1) or BP (C) control with a wide-range pyrometer |

50-1250 50-1600 600-2200 1300-2500 |

| Heating type |

resistive |

| Permissible mass with parts, kg |

1-35 |

| Available oxygen removal methods |

nitrogen or inert gas purge, fore-vacuum pumping, multi-stage |

| Range of heating / cooling speeds, ° C / min |

3-25 |

| Working gases |

hydrogen, helium, nitrogen, argon, methane, formgas |

| Number of inputs for working gases |

2-6 |

| Available operations with working gases |

mixing moisturizing |

| Minimum percentage of each gas when mixed, % |

5 |

| Range of automatic adjustment of the flow rate of each gas, l / min |

30-600 |

| Ability to use as a vacuum or gas vacuum furnace |

yes |

| Types of pumping systems |

oil (rotary vane + diffusion pumps), oil-free (dry scroll + turbomolecular pumps) |

| The uniformity of temperature in the working space without loading the electric furnace with automatic control of maintaining the temperature in the steady state, ° C, is not worse |

±5±0,005t |

| Stability of maintaining the operating temperature in the working area when controlling heating in automatic mode, ° C, not worse |

±3±0,0015t |

| Heaters power consumption, kVA |

15-50 |

|

Total dimensions, mm, no more than:

length: width high |

2300 1500 2500 |

| Weight, kg, no more than |

2750 |

Large-volume bell lift type furnaces

This type of furnace is designed for serial or large-scale production, as well as for processing large products. A design feature of this type of furnace is a monoblock assembled heating unit, mounted on the walls and cover of the hood, so that the heating unit rises with the hood. Two powerful screw hoists provide a smooth rise and lowering of each hood. Thanks to the precision execution of the mechanical assembly of the lifting mechanism, any jerking, seizing and vibration are practically eliminated.

After raising the hood, horizontal loading of the cages with products under the hood is possible, which is especially true with a large mass of parts. With this configuration, a phased installation of the cage and parts in the cage is possible, which significantly increases the number of products.

As a rule, such furnaces are made by double-bell with alternating heating caps. Heating elements can be of a cylindrical and wire type, from high-temperature alloys of resistance (nichrome, eurofechral, kanthal A1), molybdenum, less often from tungsten. It is possible to install an all-welded heater of complex design made of tungsten or molybdenum. The large volume of the chamber allows the manufacture of furnaces of this design with multi-zone heating.

| Chamber quantity, items |

2 |

| Type of chambers |

cylindrical, vertically oriented |

| Inner dimensions of chamber: diameter, mm height, mm |

250-400 300-700 |

|

Operating temperature range in the heating chamber, oC: control by thermocouples PP(S) or PR(B) control by thermocouples BP(A1) or BP(C) |

50-1250 50-1600 600-2000 |

| Heating type |

resistive |

| Permissible mass with parts, kg |

10-80 |

| Available oxygen removal methods |

purging with nitrogen or inert gas, evacuation pumping, multi-stage |

| Range of heating / cooling speeds, ° C / min |

3-25 |

| Working gases |

hydrogen, helium, nitrogen, argon, methane, formgas |

| Number of inputs for working gases |

2-6 |

| Available operations with working gases |

mixing, moisturizing |

| Minimum percentage of each gas when mixed, % |

5 |

| Range of automatic adjustment of the flow rate of each gas, l / min |

50-1200 |

| Ability to use as a vacuum or gas vacuum furnace |

yes |

| Types of pumping systems |

oil (rotary vane + diffusion pumps), oil-free (dry scroll + turbomolecular pumps) |

| The uniformity of temperature in the working space without loading the electric furnace with automatic control of maintaining the temperature in the steady state, ° C, is not worse |

±7±0,005t |

| Stability of maintaining the operating temperature in the working area when controlling heating in automatic mode, ° C, not worse |

±5±0,0015t |

| Heaters power consumption, kVA |

35-100 |

|

Total dimensions, mm, no more than: length: width high |

2600 1600 2850 |

| Weight, kg, no more than |

3750 |

Electric vacuum bell-type furnace sequiped with moving hearth bottom

This type of furnace is designed for processing large-sized products, putting and uoutputting of which is provided using special putting mechanisms, as well as for serial and large-scale production. A structural feature of this type of furnace is a fixed bell, inside of which screen insulation and a heating unit are fixed on the walls and the cover of the hood. Two powerful screw lifts provide a smooth rise and lowering of the hearth bottom, without jerking vibration and jamming.

After lowering the hearth bottom, horizontal putting of the cage with products under the hood is possible, which is especially true for a large mass of parts. With this configuration, a phased installation of the batch is possible, which significantly increases the number of products. After putting, the batch with the details rises with the hearth bottom into the working area of the heating chamber.

As a rule, such furnaces are made with one-bell. Heating elements are often collapsible, assembled from bars of cylindrical section, from high-temperature alloys of resistance (nichrome, eurofechral, kanthal A1), molybdenum, tungsten. The location of the cap allows for convenient replacement of failed elements and maintenance, without disassembling the main cap. It is possible to install an all-welded heater of complex design made of tungsten or molybdenum. The large volume of the chamber allows the manufacture of furnaces of this design with multi-zone heating. Due to the collapsible design, such furnaces are convenient to transport and assemble at the place of operation.

| Chamber quantity, items |

1 |

| Type of chambers |

cylindrical, vertically oriented |

|

Inner dimensions of chamber:

diameter, mm height, mm |

350-600 400-710 |

|

Operating temperature range in the heating chamber, oC: control by thermocouples PP(S) or PR(B) control by thermocouples BP(A1) or BP(C) |

50-1250 50-1600 600-2100 |

| Heating type |

resistive |

| Permissible mass with parts, kg |

50-200 |

| Available oxygen removal methods |

purging with nitrogen or inert gas, evacuation pumping, multi-stage |

| Range of heating / cooling speeds, ° C / min |

3-25 |

| Working gases |

hydrogen, helium, nitrogen, argon, methane, formgas |

| Number of inputs for working gases |

2-6 |

| Available operations with working gases |

mixing, moisturizing |

| Minimum percentage of each gas when mixed, % |

5 |

| Range of automatic adjustment of the flow rate of each gas, l / min |

50-2400 |

| Ability to use as a vacuum or gas vacuum furnace |

yes |

| Types of pumping systems |

oil (rotary vane + diffusion pumps), oil-free (dry scroll + turbomolecular pumps) |

| The uniformity of temperature in the working space without loading the electric furnace with automatic control of maintaining the temperature in the steady state, ° C, is not worse |

±10±0,005t |

| Stability of maintaining the operating temperature in the working area when controlling heating in automatic mode, ° C, not worse |

±5±0,0015t |

| Heaters power consumption, kVA |

50-250 |

|

Total dimensions, mm, no more than:

length width (depth) height |

3200 2600 3600 |

| Weight, kg, no more than |

4800 |

Small-size electric vacuum bell-type furnaces equiped with moving hearth bottom

This type of furnace is designed for precision processing of small batches of products, products of non-standard shapes, as well as for laboratory and scientific research. A structural feature of this type of furnace is a fixed bell, inside of which screen insulation and a heating unit are fixed on the walls and the cover of the hood. A special hearth movement mechanism provides a smooth rise and lowering of the hearth, without jerking vibration and jamming.

After lowering the hearth bottom, horizontal putting of the batch with products under the hood is possible at a level convenient for the operator, which provides additional control and increases safety during operation. After inputting, the batch with the details rises with the hearth bottom into the working area of the heating chamber.

Such furnaces are made one-bell type. Heating elements can be of a cylindrical and strip type, from high-temperature resistance alloys (nichrome, eurofechral, kanthal A1), molybdenum, tungsten, tungsten-rhenium alloy. It is possible to create a furnace with a precision atmosphere, suitable for high-precision and extremely clean processes. Often, these furnaces are made in a modular design.

| Chamber quantity, items |

1 |

| Type of chambers |

cylindrical, vertically oriented |

|

Inner dimensions of chamber: diameter, mm height, mm |

60-250 80-450 |

|

Operating temperature range in the heating chamber, оС: control thermocouples ХА (K) or НН (N) control thermocouples PP (S) or PR (B) control thermocouples BP (A1) or BP (C) control with a wide-range pyrometer |

50-1250 50-1600 600-2200 1300-2500 |

| Heating type |

resistive |

| Permissible mass with parts, kg |

1-20 |

| Available oxygen removal methods |

purging with nitrogen or inert gas, evacuation pumping, multi-stage |

| Range of heating / cooling speeds, ° C / min |

3-25 |

| Working gases |

hydrogen, helium, nitrogen, argon, methane, formgas |

| Number of inputs for working gases |

2-6 |

| Available operations with working gases |

mixing, moisturizing |

| Minimum percentage of each gas when mixed, % |

5 |

| Range of automatic adjustment of the flow rate of each gas, l / min |

25-60 |

| Ability to use as a vacuum or gas vacuum furnace |

yes |

| Types of pumping systems |

oil (rotary vane + diffusion pumps), oil-free (dry scroll + turbomolecular pumps) |

| The uniformity of temperature in the working space without loading the electric furnace with automatic control of maintaining the temperature in the steady state, ° C, is not worse |

±5±0,003t |

| Stability of maintaining the operating temperature in the working area when controlling heating in automatic mode, ° C, not worse |

±2±0,0015t |

| Heaters power consumption,kVA |

20-50 |

|

Total dimensions, mm, no more than: length width (depth) height |

2200 1800 2400 |

| Weight, kg, no more than |

2850 |

Shaft and chamber furnaces

Shaft furnace - chamber-type resistance electric furnace with a sealed chamber and a removable cover and vertical loading. Chamber electric furnace - electric resistance furnace with a sealed chamber and a hinged or sliding cover and horizontal loading.

A structural feature of this type of furnace is the stationary position of the chamber and heaters in conjunction with a movable cover or door. The volume of the working zone of the produced furnaces of this type exceeds 150 m3, and the degree of vacuum maintained reaches 6.5 • 10-2 Pa. It is also possible high-vacuum pumping inlet controlled atmosphere.

This type of furnace provides ease of use and the ability to process parts of particularly large dimensions. At the same time, the furnaces have optimal maintainability. This type of furnace is suitable for multi-zone execution, which helps to minimize the temperature gradient inside the chamber. The use of modern heat-insulating materials minimizes heat loss and, as a consequence, reduces powerconsumption.

Heating elements can be of almost any shape from any high-temperature resistance alloy (nichrome, eurofechral, kanthal A1), molybdenum and tungsten alloys. The structure of the heater is usually collapsible, which allows you to replace the part of the heater that requires replacement during maintenance, without affecting the rest of the elements.

The main advantages of shaft and chamber furnaces:

Scope: annealing, tempering, normalization of large-sized products and structures made of stainless and stainless steels, gas quenching, cementation, nitriding, etc.

| Chamber quantity, items |

1 |

| Form of the chamber |

цилиндрическая или прямоугольная |

|

Inner dimensions of chamber minimum, mm: maximum, mm: |

120-200 24000 и более |

| Operating temperature range in the heating chamber, оС

control thermocouples ХА (K) or НН (N) control thermocouples PP (S) or PR (B) control thermocouples BP (A1) or BP (C) |

100-1250 100-1600 600-2150 |

| Heating type |

resistive |

| Permissible mass with parts, kg |

1-25000 |

| Available oxygen removal methods |

forevacuum pumping |

| Range of heating / cooling speeds, ° C / min |

1-20 |

| Working gases |

nitrogen, argon, methane, ammonia, formgas, other gases as agreed |

| Number of inputs for working gases |

1-12 |

| Available operations with working gases |

mixing, moisturizing |

| Minimum percentage of each gas when mixed, % |

5 |

| Range of automatic adjustment of the flow rate of each gas, l / min |

30-12000 and more |

| Ability to use as a vacuum or gas vacuum furnace |

yes |

| Ability to use as a convection chamber |

yes |

| Types of pumping systems |

oil (rotary vane + diffusion pumps), oil-free (dry scroll + turbomolecular pumps) |

| The uniformity of temperature in the working space without loading the electric furnace with automatic control of maintaining the temperature in the steady state, ° C, is not worse |

±7±0,005t |

| Stability of maintaining the operating temperature in the working area when controlling heating in automatic mode, ° C, not worse |

±5±0,0015t |