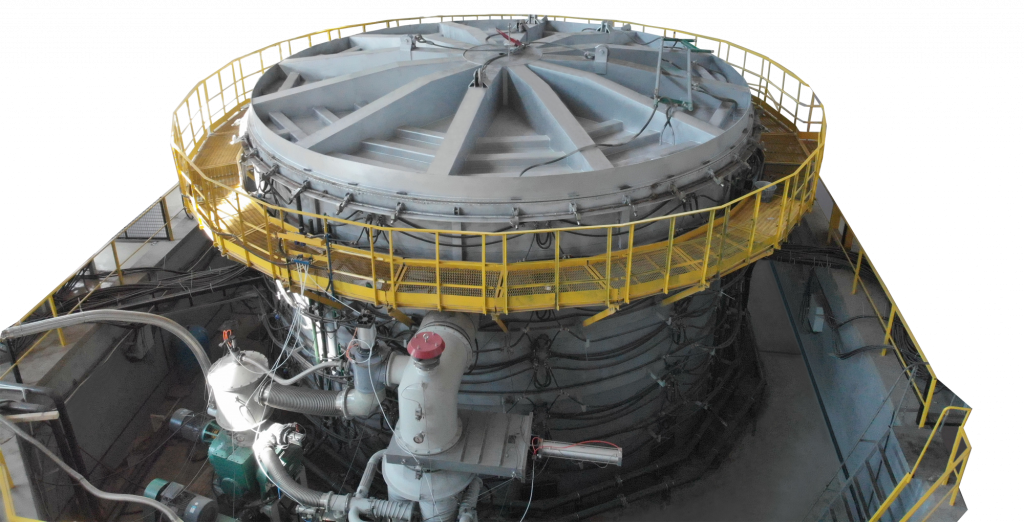

Large-scale vacuum shaft furnace

This cylindric vertical furnace with effective diameter 8m and 4.5m high is designed to perform vacuum annealing of welded structures from martensitic and austenitic steels to release internal stresses.

We produce furnaces for thermal treatment of metals and alloys, metallurgy, chemical and thermal annealing of different materials, vacuum-hydrogen furnaces, as well as auxiliary hardware and general-purpose customized purposes as requested by Customer.

Components:

-

Vacuum chamber housing 8 m in diameter with removable upper cover;

-

Special high temperature facing;

-

Maintenance platform;

-

Vacuum pumping system, based on plunger pumps, Roots-type pumps, booster oil and steam pumps;

-

Pneumatic system;

-

Electric heaters;

-

Water cooling system;

-

Supply and control system.

When producing crucial welded structures, in particular the vacuum chambers, the inner structure is subject to stresses. After few years of intensive use can result in destruction of the structure. In vacuum chamber such consequence may lead to the leakage, and consequently full loss of operation capacity of the chamber.

In order to address this issue, one has designed, manufactured and launched an electric resistance furnace for thermal treatment that enables to perform annealing and tempering of structures and housing modules for vacuum chambers up to 6.5 m in diameter and up to 4 m high.

In order to measure the operating temperature inside the chamber every area is equipped with thermoelectric transformer (thermocouple); one is mounted on top of the cover in order to perform measurements in the central part. The bottom part is equipped with the grids made of heat resistive cast iron to protect the facing from damage.

The vacuum system includes two pumping lines with respect to the furnace for thermal treatment of opposite pieces.

The composition of the hardware in both pumping lines is the same and encompasses a booster oil and vapor pump, forepump (double rotor Roots vacuum pump and plunger vacuum pumps). In order to optimize the loadthe double rotor Roots pump is exposed to, the system is equipped with bypass pumping lines.

The main advantage of vacuum thermal treatment is no oxidizing and carbon residue or any other contamination left on the metal surface, so there is no need to perform sand blasting or other cleaning.

| Maximal heating temperature, oC |

До +1000 |

| Maximal fluctuations of the set temperature within heating zones, oC, not to exceed |

±10 |

| Residual pressure in the heating chamber, Pa (mm Hg) |

6.65-10 2(5*104) |

| Number of heating zones, pcs |

12 |

| Water operating pressure in cooling system, MPa (kgs/cm2) |

0.35 - 0.4 (3.5 - 4.0) |

| Water flowrate of cooling system, m3/h |

30 |

| Operating air pressure in pneumatic system, MPa (kgs/cm2) |

0.4-0.6 (4-6) |

| Air flowrate in pneumatic system, m3/h |

6 |

| Mass of the loaded item, kg, not to exceed |

20000 |

|

Dimensions of the loaded item, mm, not to exceed: width across corners height |

6500 4000 |

| Fixed power, MW, not to exceed |

1.9 |

| Nominal voltage, V |

3N 380 |

| Current frequency, Hz |

50 |

| Furnace operating modes |

manual automated |

|

Overall dimensions of the furnace without electric hardware, mm, not to exceed: Length Width Height |

14050 12500 6100 |

|

Dimensions with electrical equipment, mm, not to exceed: Length Width Height |

16600 15000 6100 |

|

Dimensions of the pit for furnace mounting mm, not to exceed: Length Width Height |

15300 11300 2400 |

| Mass of the furnace, kg, not to exceed |

265000 |